Positioning device for dry-type motor rotor hot jacket

A technology of motor rotor and positioning device, which is applied in the manufacture of stator/rotor body, etc., which can solve problems such as shaking, inconvenient locking of motor rotor, inconvenient positioning and locking of motor rotor, etc., and achieves the effect of occupying less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

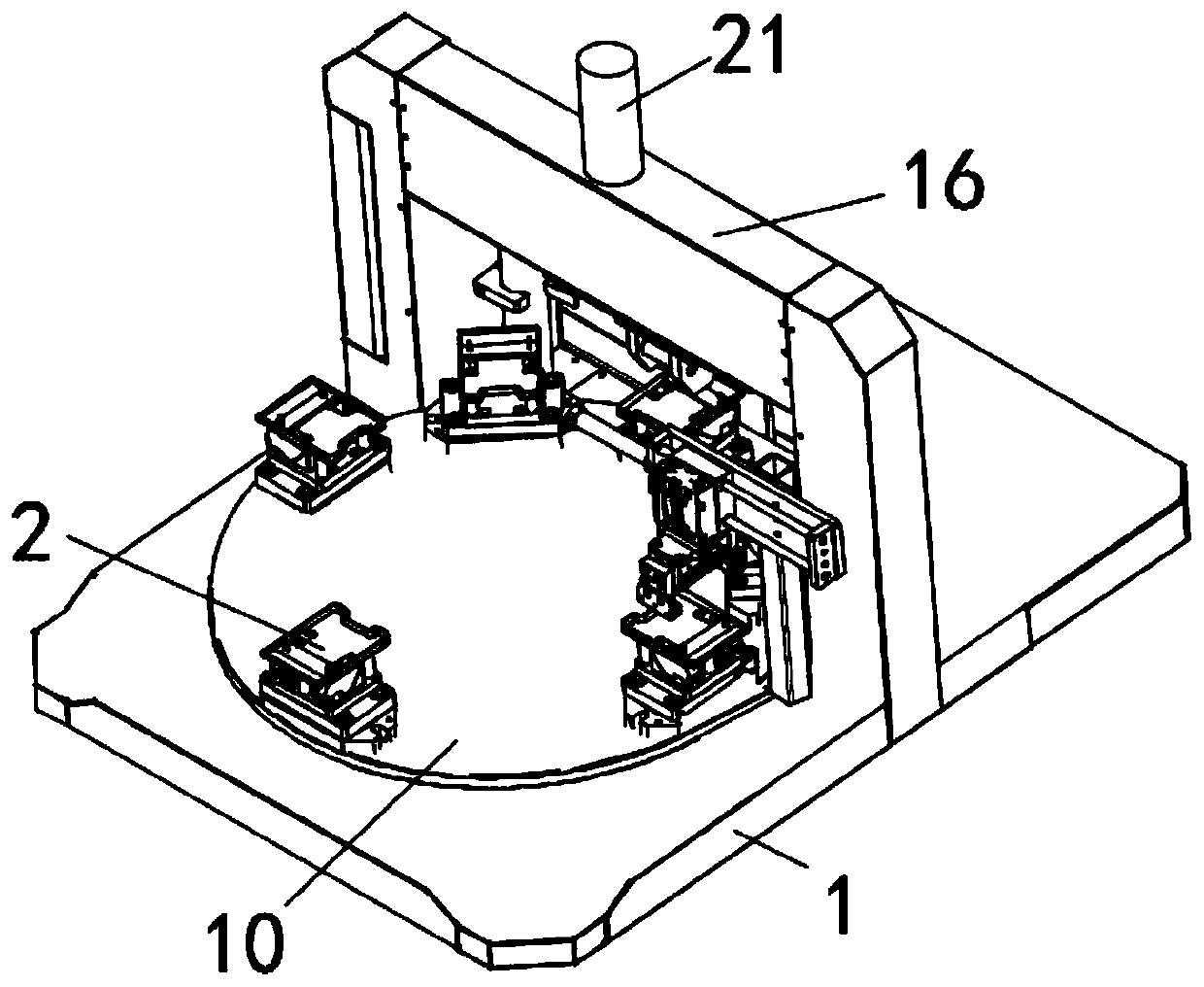

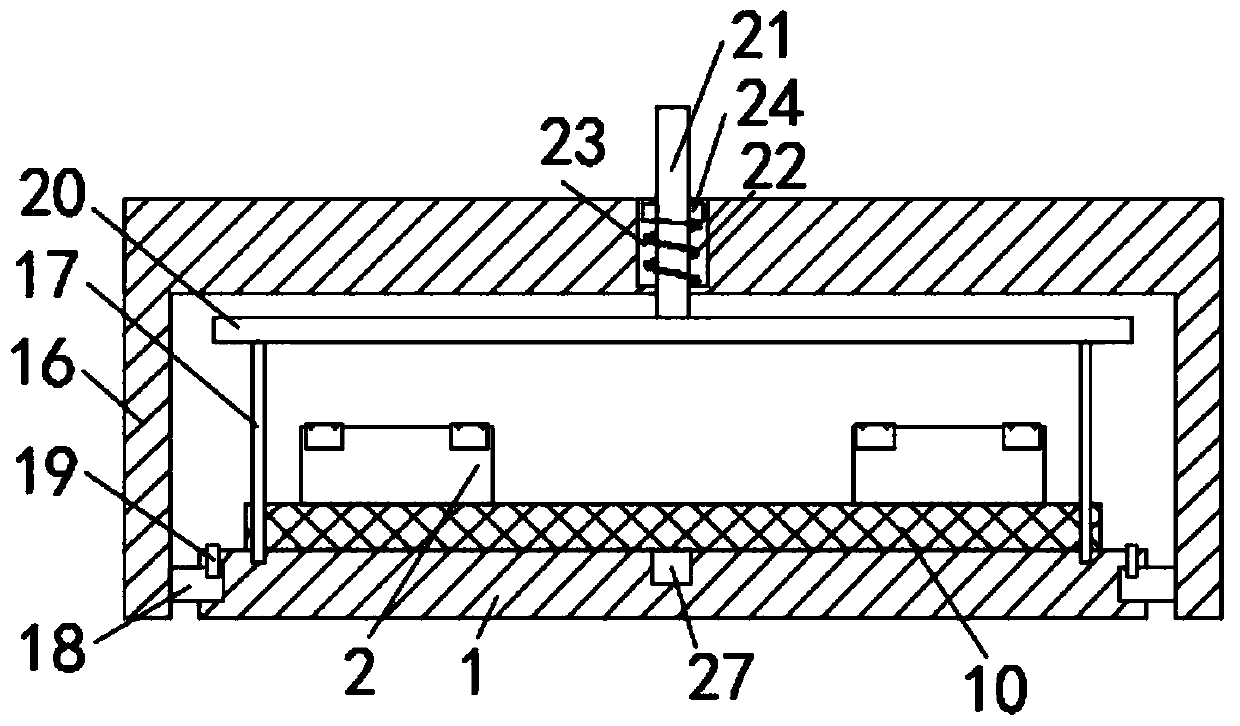

[0040] A positioning device for dry-type motor rotor shrink fit, including a bottom plate 1 and at least one set of positioning components 2 rotationally connected on the bottom plate 1; the positioning component 2 includes a fixed clamping plate 3, a moving clamping plate 4 and a bearing plate 5;

[0041] The lower end of the fixed clamping plate 3 is vertically fixedly connected with a fixed plate 6, and the fixed plate 6 is rotatably connected to the upper surface of the bottom plate 1;

[0042] The movable clamping plate 4 is connected above the fixed plate 6 through an adjustment mechanism;

[0043] The carrying plate 5 is symmetrically fixedly connected to the left and right side walls of the fixed clamping plate 3, and the carrying plate 5 is located between the movable clamping plate 4 and the fixed clamping plate 3, and the lower end of the carrying plate 5 faces upwards to provide an accommodating space 7. The upper end surface of the bearing plate 5 is provided with...

Embodiment 2

[0052] A dry-type motor rotor 28 shrink-fit positioning device, including a bottom plate 1 and at least one set of positioning components 2 rotatably connected on the bottom plate 1; the positioning component 2 includes a fixed clamping plate 3, a moving clamping plate 4 and a bearing plate 5;

[0053] The lower end of the fixed clamping plate 3 is vertically fixedly connected with a fixed plate 6, and the fixed plate 6 is rotatably connected to the upper surface of the bottom plate 1;

[0054] The movable clamping plate 4 is connected above the fixed plate 6 through an adjustment mechanism;

[0055] The carrying plate 5 is symmetrically fixedly connected to the left and right side walls of the fixed clamping plate 3, and the carrying plate 5 is located between the movable clamping plate 4 and the fixed clamping plate 3, and the lower end of the carrying plate 5 faces upwards to provide an accommodating space 7. The upper end surface of the bearing plate 5 is provided with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com