Dipping and scalding machine for poultry meat slaughtering and processing production line

An assembly line and poultry meat technology, applied in poultry processing, slaughtering, meat processing, etc., can solve the problems of uneven scalding, adding water, uncontrollable scalding time and temperature, etc., and achieve the effect of easy hair removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

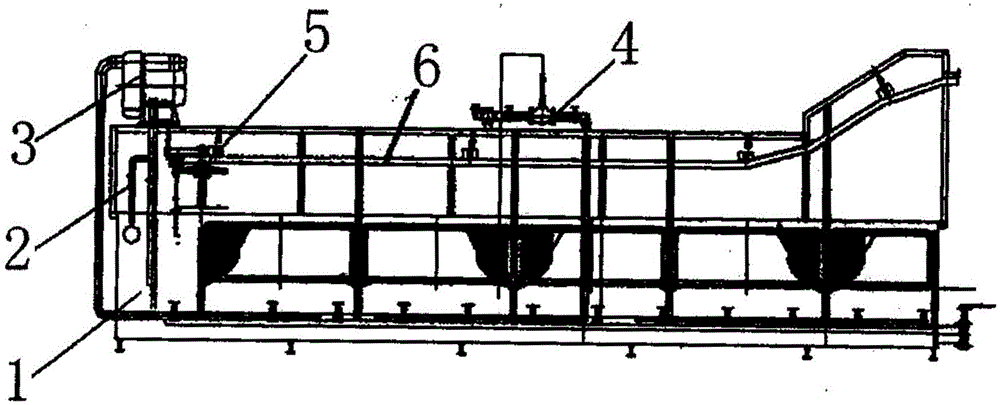

[0009] Such as figure 1 As shown, the present invention is provided with an automatic water supply control system 2 at the inner end of the pool body 1, the air blower assembly 3 is arranged on the top of one end of the pool body 1, and a temperature regulating valve 4 is arranged on the upper middle part of the pool body 1, and the conveying The guide rail 5 is provided at the upper inner end of the pool body 1 through the guide support wheel 6. With the above arrangement, hot water is added to the pool body 1 of the present invention through the automatic water supply control system 2, and the air blower assembly 3 makes the hot water in the pool body 1 boil, and circulates the poultry hair hanging on the conveying rail 5 Soaking, with high production efficiency, sanitation and tidy, easy to operate and use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com