Ultrasonic spraying device for atomizing viscous liquid and suspension liquid

A spray device and ultrasonic technology, applied in the field of ultrasonic spray devices and liquid spray devices, can solve the problems of low atomization amount, easy blockage of microporous metal sheet micropores, limited amplitude of metal sheet, etc., achieve broad application prospects, improve fog The effect of atomization ability and atomization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

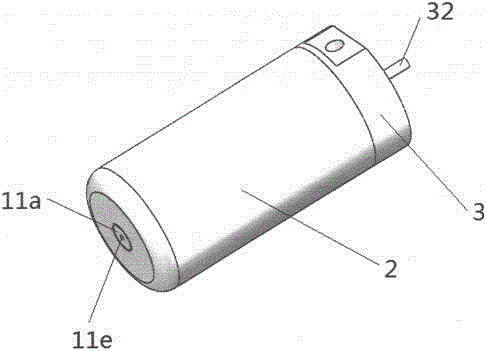

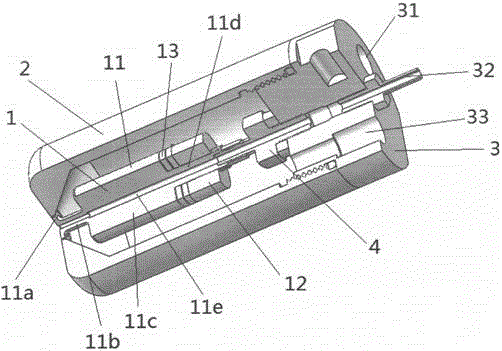

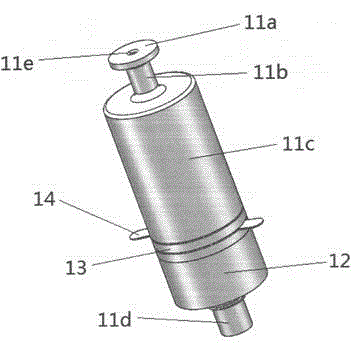

[0016] Such as figure 1 and figure 2 As shown, the present invention discloses an ultrasonic spray device for atomizing viscous liquids and suspensions, which includes a rear seat 3 , a transducer 1 and a housing 2 . The transducer 1 is fixed on the back seat 3 through a connecting rod 4, the shell 2 is covered outside the transducer 1 and connected to the front side of the back seat 3, and the rear side of the back seat 3 is respectively connected with electrical ports 31, Liquid inlet port 32 and air inlet port 33. The inner front half of the housing 2 is a conical cylindrical structure, and the second half is a cylindrical structure. There is a circular hole outlet at the center of the front end of the housing 2, and the atomizing end 11a of the transducer front end 11 is located at the outlet of the circular hole. . The position of the central axis of the transducer 1 runs through a straight through hole 11e with a diameter of 1.2 mm. During operation, the liquid ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com