Manual mesh stretching handle easy to operate

A technology of handle and stretch net, applied in the field of manual stretch net handle, can solve problems such as inconvenient operation, and achieve the effects of safe operation, strong stability, and easy handling and movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An easy-to-operate hand-stretched net handle comprises two fixed ends and a pulling part, the pulling part is located between the two fixed ends, and the surface of the pulling part is covered with a layer of flexible material. There is a 90° arc between the pulling part and the fixed end of the handle. The handle is made of stainless steel, and the flexible material is made of rubber.

Embodiment 2

[0020] An easy-to-operate hand-stretched net handle comprises two fixed ends and a pulling part, the pulling part is located between the two fixed ends, and the surface of the pulling part is covered with a layer of plastic material. There is a 90° arc between the pulling part and the fixed end of the handle. The handle is made of copper material.

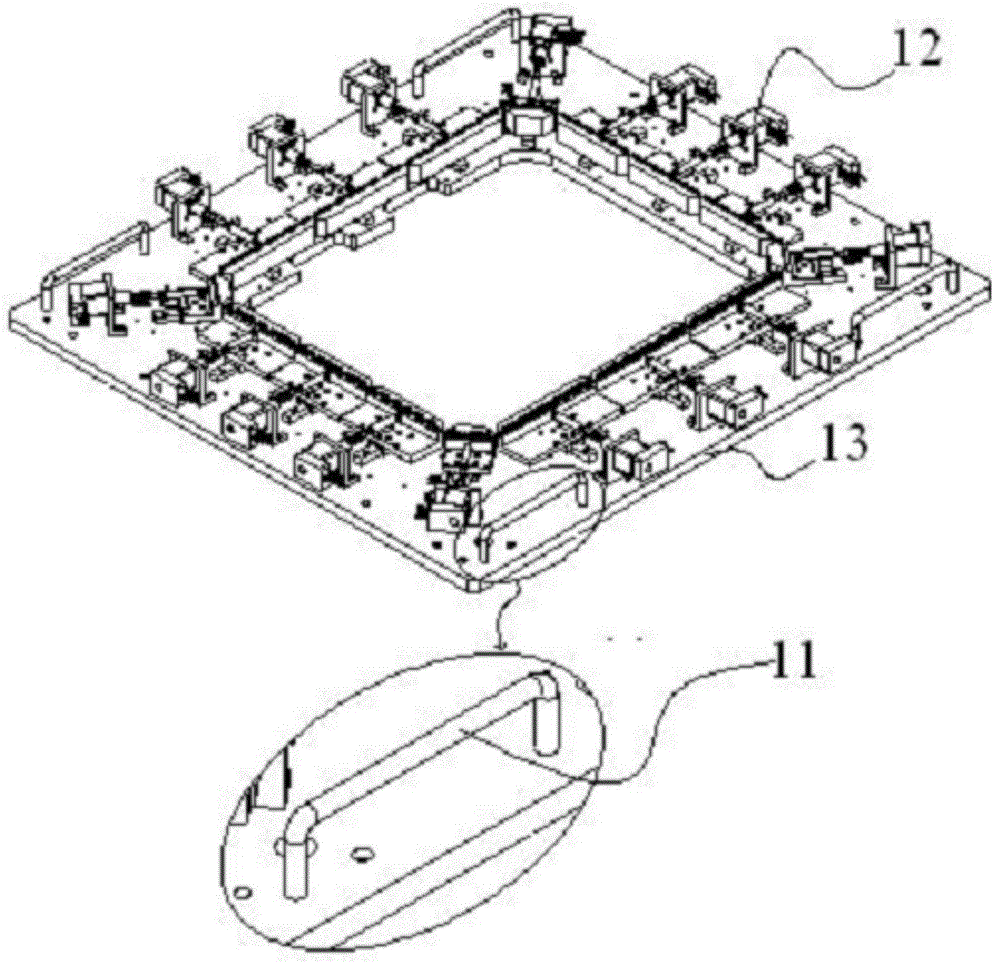

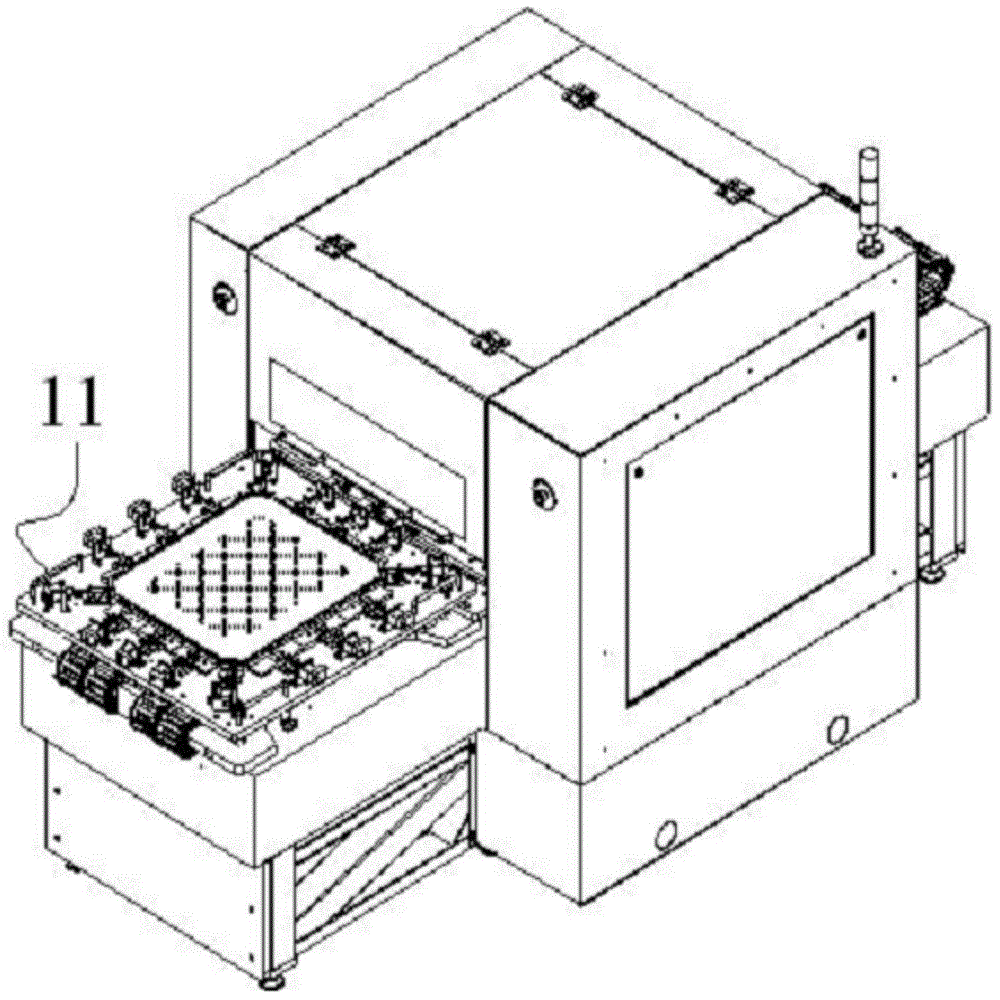

[0021] Such as figure 1 As shown, a hand-stretching handle that is easy to operate, the stretching mechanism is composed of several stretching equipment 12, a fixed base 13 and other related fixing mechanisms, and a handle 11 for moving the stretching mechanism is fixed on the base 13 .

[0022] There are 4 handles on the base 13 in the present embodiment, and the handle 11 is fixed near the edge of the base 13 of the stretching net mechanism, and the specific positions are as follows: figure 1 As shown; the handle 11 is made of hard stainless steel metal material; in order to prevent hand injury, the surface of the handle is wr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com