Electric screw driver with adjustable rotating speed

An electric screwdriver, speed technology, applied in the direction of transmission components, motor tools, transmission devices, etc., can solve the problems of inability to adjust the speed, complex structure, easy to produce impact, etc., achieve good torque conversion effect, compact structure, and easy to carry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] This embodiment is an electric screwdriver with adjustable rotational speed.

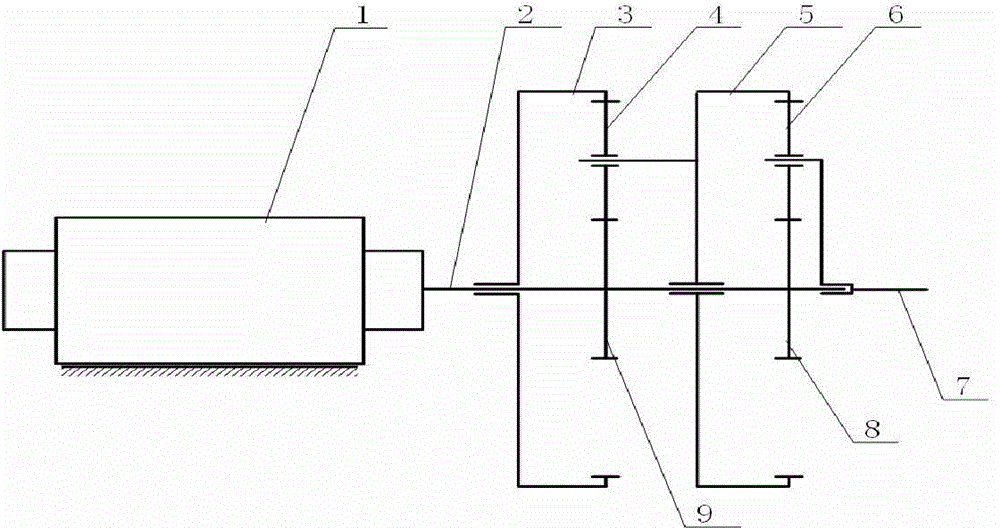

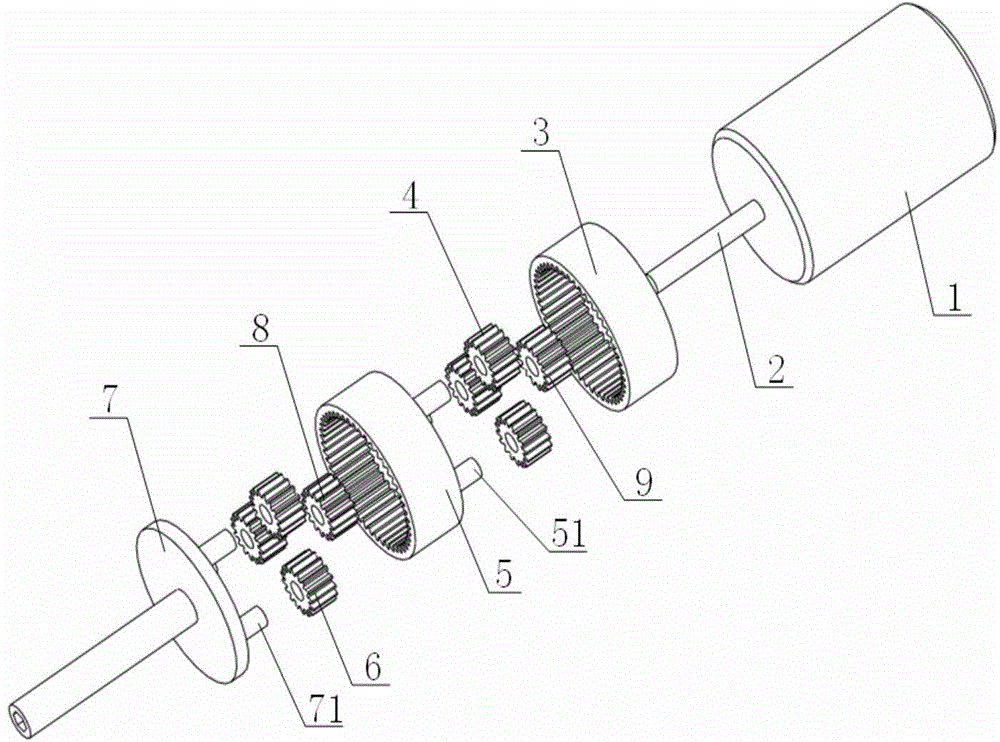

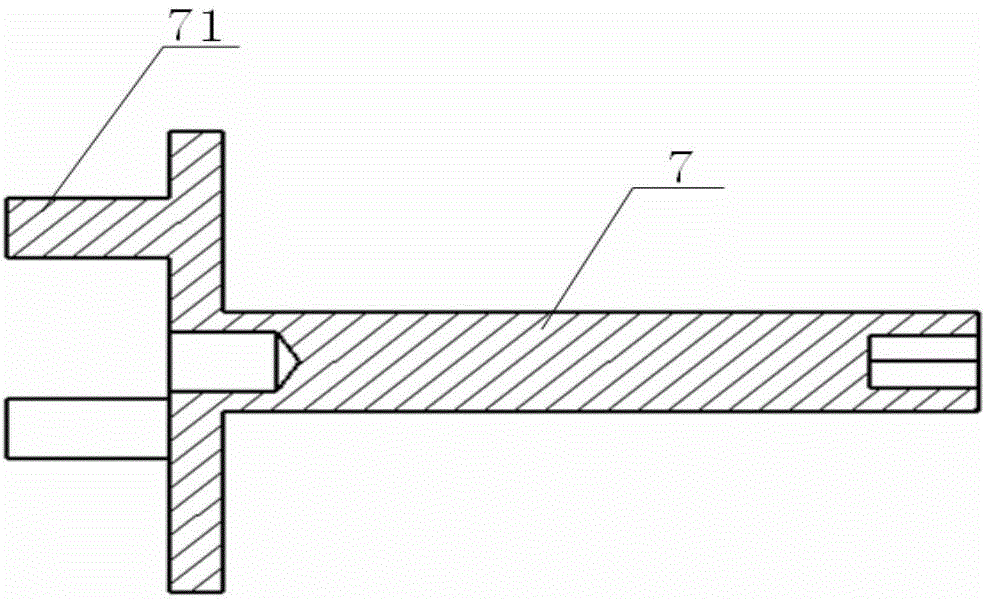

[0018] see figure 1 , figure 2 , image 3 , The electric screwdriver with adjustable speed of the present invention is composed of a motor, a combined gear train reducer, and a cutter rod drive shaft. The combined gear train reducer is fixed in the middle part of the electric screwdriver, the motor is located at the side end of the combined gear train reducer, and the knife rod drives The shaft is fixed on the other side end of the combined gear train reducer and is fixedly connected with the cutter bar. The combined gear train reducer is composed of a first-stage planetary gear train and a second-stage planetary gear train, including a first driving gear 9, a first sun gear 3, a first planetary gear 4, a second driving gear 8, a second sun gear 5, The first planetary gear shaft 51, the second planetary gear 6; the first sun gear 3 and the second sun gear 5 are both ring gears; the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com