Hand-operated pulley for substation

A technology of substations and pulleys, which is applied in the direction of electrical components, portable lifting devices, switchgear, etc., can solve the problems of affecting work efficiency, increasing the tension of the pull rope body, and not being easy to disassemble, etc., to achieve increased work efficiency, simple and compact structure, Effects that are cheap to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

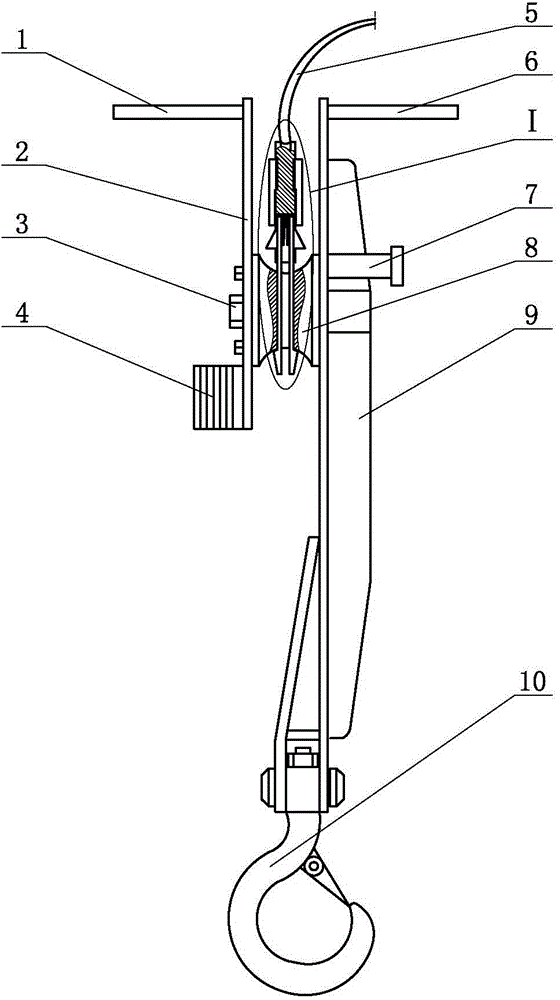

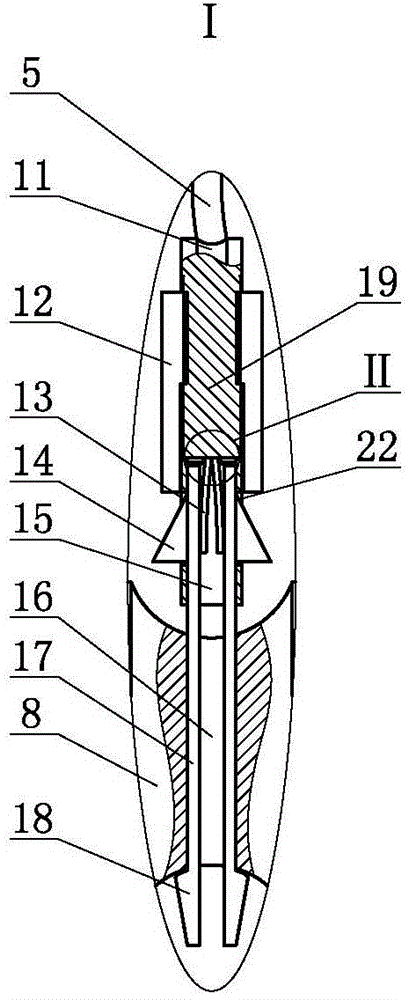

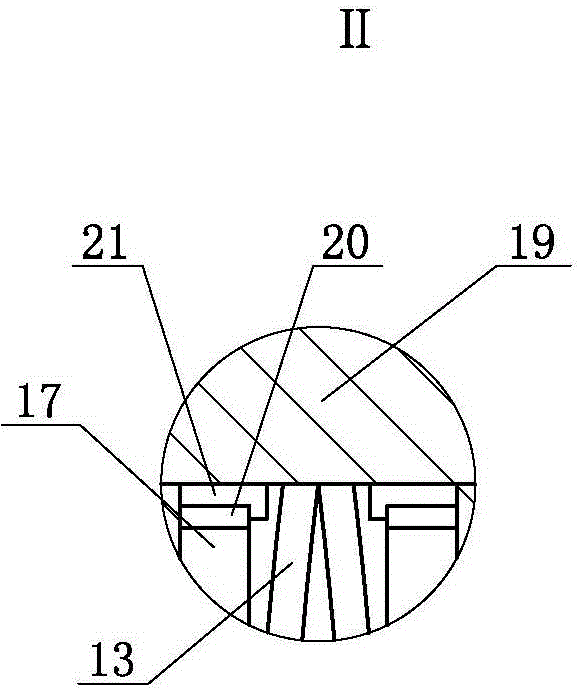

[0009] Substation hand block, such as figure 1 Shown, comprise tackle support 9, the middle part of tackle support 9 one side is fixed support shaft 3, and pulley 8 is installed on support shaft 3, and rocker 1 is housed on the pulley 8, and safety hook 10, pulley 8 are installed on the lower end of tackle support 9. Provide a through hole 16 on the top, and two straight rods 17 are arranged in the through hole 16, and the active force is evenly distributed on the two straight rods 17, and the two straight rods 17 interact, and the width of the straight rods 17 after being brought together is the same as that of the through holes 16. Corresponding inner diameters keep compact. The two ends of each straight rod 17 are outside the through hole 16, the lower end of the straight rod 17 is provided with a wedge-shaped head 18, the tip of the wedge-shaped head 18 is downward, and the wedge-shaped head 18 is convenient to enter the through-hole 16 from top to bottom in the direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com