Construction method for blowdown system of converter vaporization flue

A technology of vaporization flue and sewage system, which is applied in the manufacture of converters, etc., can solve the problems of reducing the efficiency of vaporization flue sewage, hindering workers' enthusiasm for work, and inconvenient maintenance, so as to reduce faults, facilitate the distribution of pipeline valves, and improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

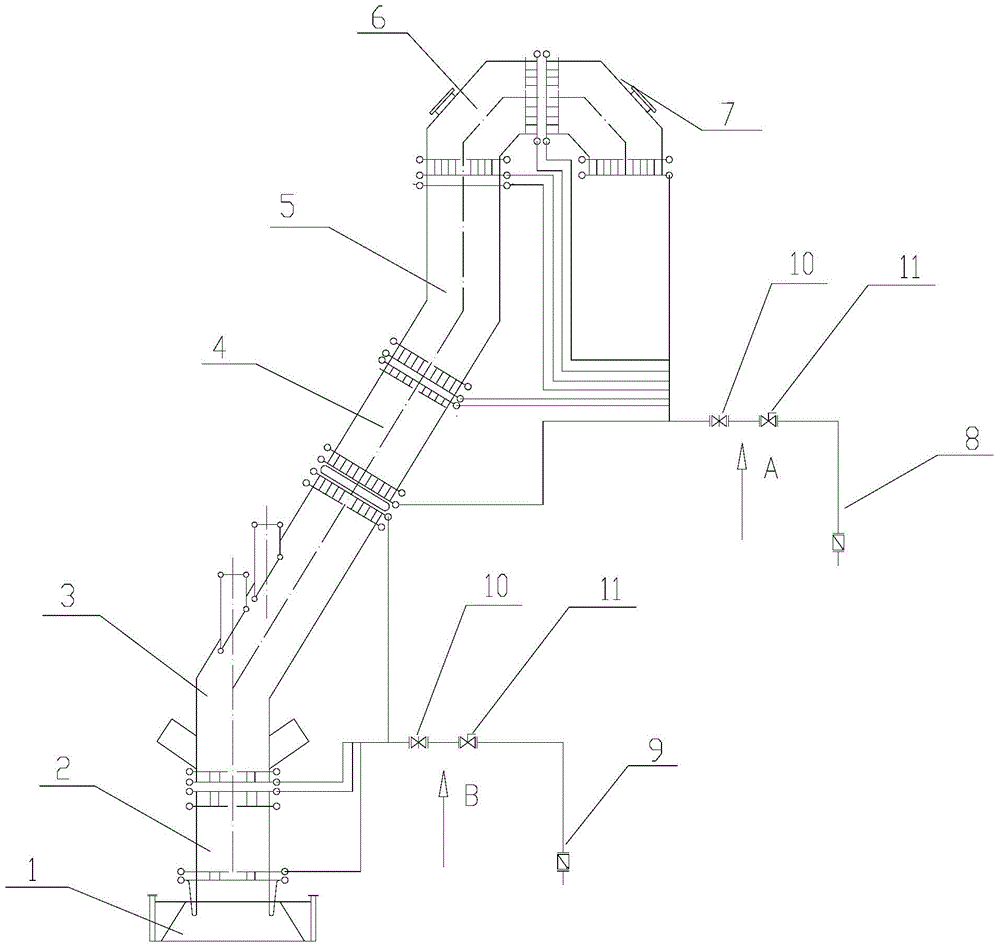

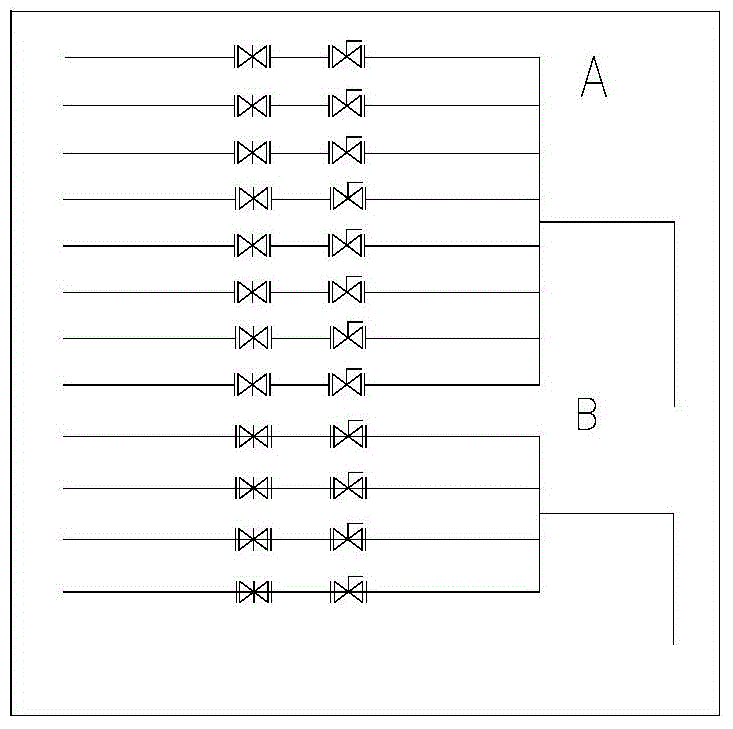

[0023] This embodiment provides a construction method for the blowdown system of the converter vaporization flue, the structure of the blowdown system of the converter vaporization flue is as follows figure 1 As shown, the converter vaporization flue has a fixed section, a moving section, a middle section, a middle section, a middle section and a final section arranged in sequence from bottom to top, the fixed section is vertically arranged, and the lower part of the moving section is the vertical section I And the upper part is the inclined part I, the inclined part I is inclined and has an acute angle with the horizontal direction, the middle section is inclined and the angle of inclination is the same as that of the inclined part I, the upper part of the second middle section is the vertical part II and the lower part is the inclined part II, inclined The inclination angle of part II is the same as that of inclined part I, and the third middle section is inclined, and the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com