High-strength hoisting pulley

A lifting pulley, high-strength technology, applied in the direction of belts/chains/gears, portable lifting devices, load hanging components, etc., can solve the problems of easy casting defects, high scrap rate, and poor thickness of groove parts, etc., to achieve The effect of avoiding casting defects, reasonable structure and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

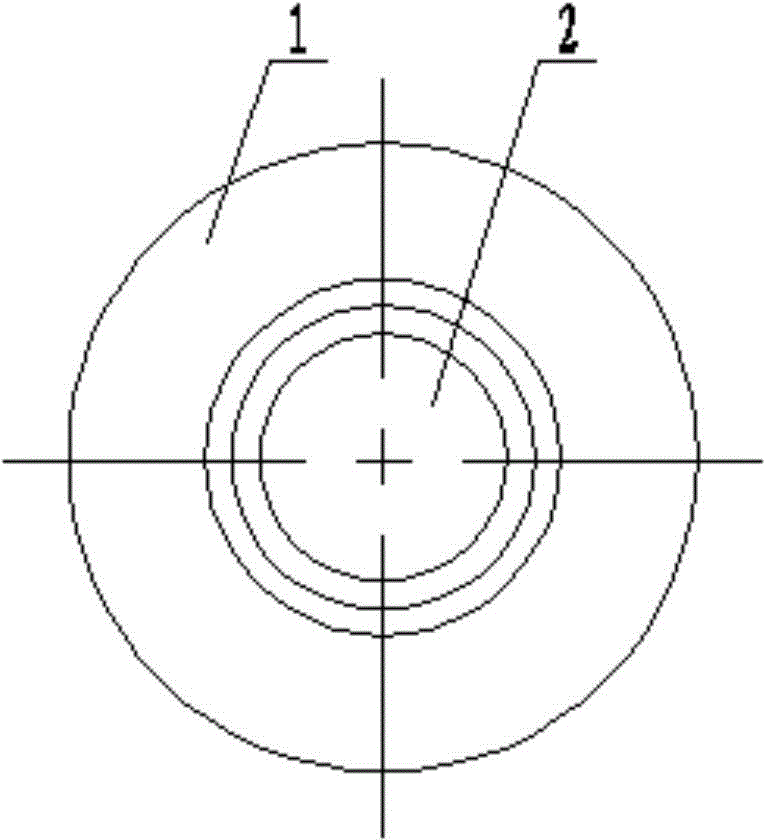

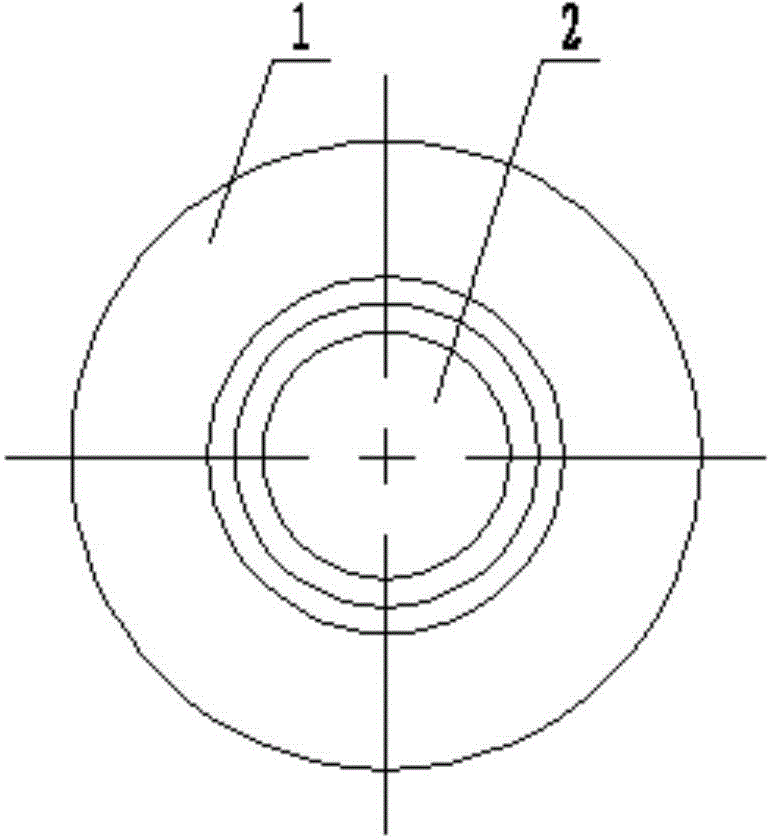

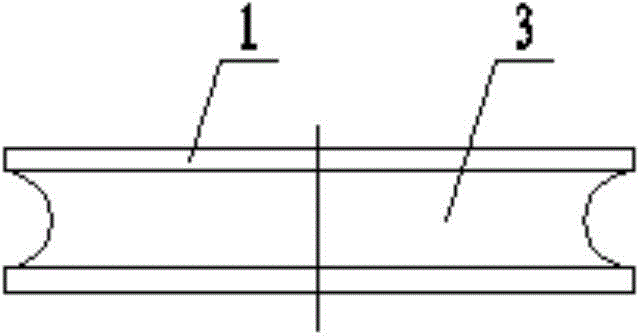

[0013] A high-strength hoisting pulley comprises a disc 1, a through hole 2 is formed on the axis of the disc, and an annular guide groove 3 is formed on the side wall of the disc. The innovation of the present invention is that: the front and back of the disc are smooth plate structures, and the disc is a Q345B manganese steel disc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com