Ecological aluminum-alloy board with electric heating devices

An electric heating device and aluminum alloy plate technology, which is applied in the field of architectural decoration, can solve the problems of high energy consumption, low thermal conductivity, and no heating of the floor, and achieve the effects of avoiding excessive heating, high thermal conductivity, and easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

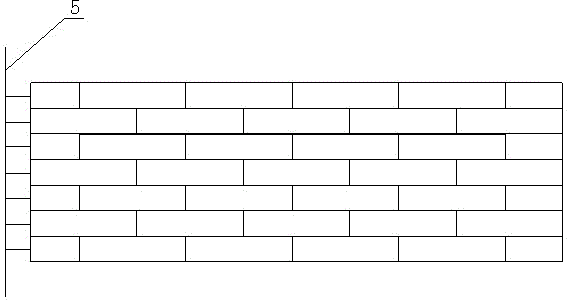

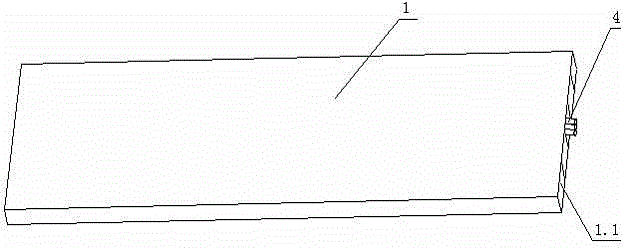

[0022] see Figure 1 to Figure 3 , the present invention relates to an ecological aluminum alloy plate with electric heating device, this ecological aluminum alloy plate uses ecological aluminum, it is formed by splicing several aluminum alloy plates 1, two adjacent aluminum alloy plates 1 are spliced left and right to form a row Aluminum alloy plates, multiple rows of aluminum alloy plates are laminated up and down to form the entire aluminum alloy floor or wall panel.

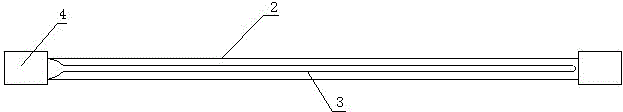

[0023] Wherein the single aluminum alloy plate 1 is provided with an aluminum plate cavity 1.1, and an electric heating device is installed in the aluminum plate cavity 1.1, and the electric heating device includes a power cord 2 and a heating wire 3, and the power cord 2, the heating wire 3 is arranged in parallel with the aluminum alloy plate 1, the heating wire 3 is a resistance wire, one end of the heating wire 3 is connected to one terminal of the power line 2, and the other end is connected to the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com