Novel body armor

A new type of body armor, which is applied in protective equipment, offensive equipment, personnel protection equipment, etc., can solve the problems of restricting the development of aramid bulletproof materials and the delay of aramid bulletproof materials, and achieves light weight, light target weight, and improved performance. The effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] First, weigh 1000g of acrylate adhesive and 10g of cross-linking agent triglycidyl isocyanurate (TGIC), add the cross-linking agent evenly into the glue, and mix the glue well for later use.

[0018] The aramid fiber is wound in parallel on the winding machine, and then the fiber is immersed in the above glue solution, and the yarn is spread by a specific spinning equipment. In this example, the above-mentioned adhesive is used. After dipping the glue, spread the glue evenly with a squeegee, and dry it under the electric resistance wire at 50°C. Orthogonal compounding of the cloth sample fibers results in two interlaced cloth samples. The corresponding product structure is [0° / 90°], and the surface density of the cloth sample is 200g / m 2 . Cut the fabric sample into a 400mm×400mm square fabric sample, remove the PE film, stack the two layers of the fabric sample in the direction of [0° / 90°, 0° / 90°], put the laminated fabric sample into the mold, and use 50t press, pr...

Embodiment 2

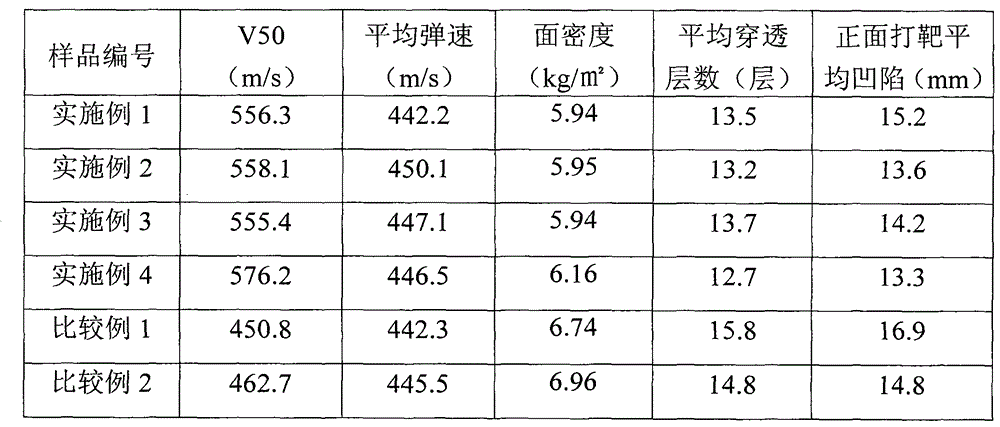

[0020] Change the cross-linking agent in Example 1 to 60g, and change the surface density of the cloth sample to 200g / m 2 All the other conditions are the same as in Example 1. Adopt Type 54 7.62mm pistol, Type 51 7.62 pistol bullet (lead core), according to GA141-2010 bulletproof level 2 test, the results are shown in Table 1.

Embodiment 3

[0022] In Example 1, the structure is changed to 20 layers of [0° / 90°] cloth samples + 2 layers of [0° / 90° / 0° / 90°] bulletproof sheets + 3 layers of [0° / 90°] cloth samples Made bulletproof chips, 51 type 7.62 pistol bullets (lead core), according to GA141-2010 bulletproof level 2 test, the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com