Soft stab-proof/bulletproof material

A stab-proof and bullet-proof technology, applied in protective equipment, offensive equipment, personnel protection equipment, etc., can solve the problems of decreased wearing comfort, poor softness of protective clothing, and increased weight of protective clothing, so as to achieve increased consumption and excellent anti-corrosion Anti-ballistic performance and the effect of reducing penetration force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

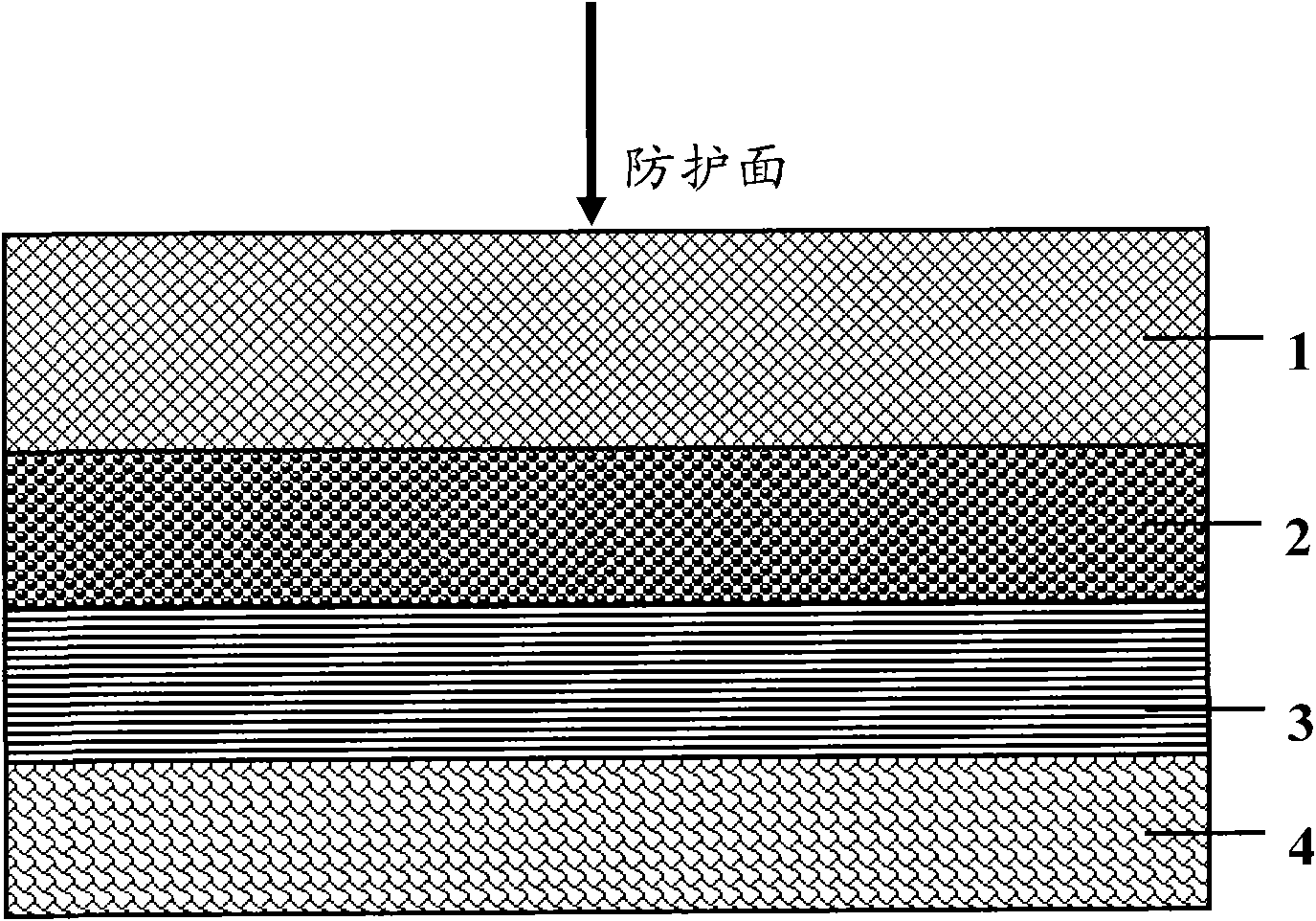

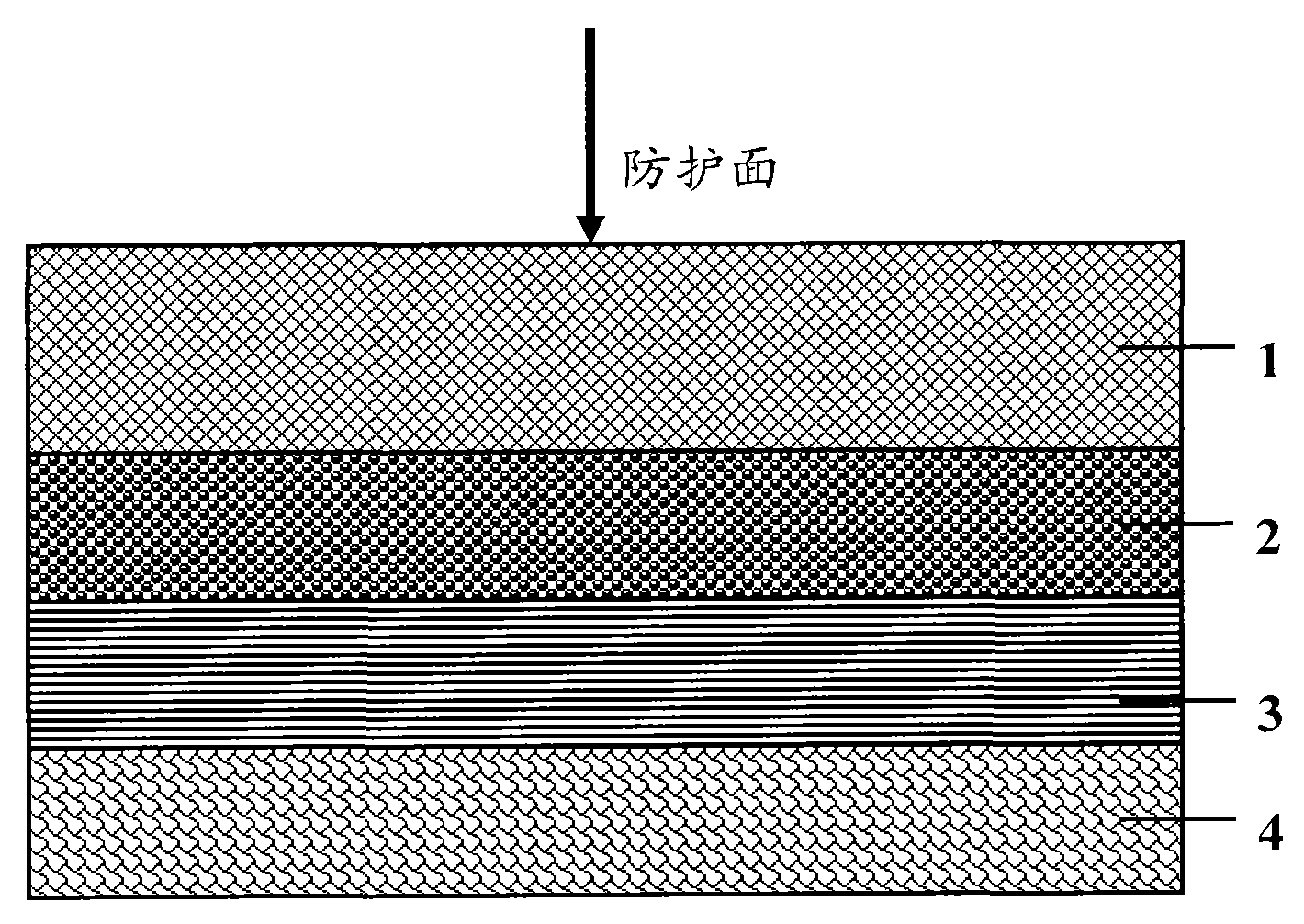

[0023] see figure 1 , the soft anti-stab and ballistic material of the present embodiment, from the outer layer (upper layer) to the inner layer (lower layer) sequentially includes: bulletproof fiber fabric layer 1, shear thickening liquid composite fiber fabric layer 2, thermoplastic resin composite fiber fabric layer 3 and shear thickening liquid syntactic foam layer4. There is no bonding between the four parts, and the layers can move relative to each other.

[0024] The bulletproof fiber fabric layer 1 is made up of at least one layer of aramid fiber (Kevlar) plain weave cloth, preferably 2-20 layers.

[0025] The fiber fabric layer 2 coated with the shear thickening liquid is composed of multiple layers of aramid fiber (Kevlar) plain weave cloth with a concentration of 10wt.% nano-silica shear thickening liquid, preferably 2-10 layers. The preparation of the composite fabric of the shear thickening liquid uses ethanol as the diluent to dilute the shear thickening liquid...

Embodiment 2

[0029] The main difference between this example and Example 1 is that the bulletproof fiber fabric layer 1 is formed by laminating and compounding 2-20 layers of fiber fabrics. , one or more of ultra-high molecular weight polyethylene fiber cloth (UHMWPE) and its UD, poly-p-phenylene benzobisoxazole fiber (PBO) fiber cloth and its UD, and high-performance nylon fiber cloth.

Embodiment 3

[0031] The difference between this example and Example 1 is mainly that the shear thickening liquid composite fiber fabric layer 2, wherein the fiber fabric is laminated and compounded by 21 layers of fiber fabric, the fiber fabric is selected from Kevlar fiber cloth, ultra-high molecular weight polyester One or more of vinyl fiber cloth, PBO fiber cloth, high-performance nylon fiber cloth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com