Fixing device for round-bar stretching sample with gap and measurement method for diameter at gap

A technology for tensile specimens and fixtures, applied in the field of mechanical testing of metal and non-metallic materials, can solve the problems of unmeasured diameter, unmeasured, and reduced accuracy, so as to achieve accurate and reliable test data, improve measurement accuracy, and meet test accuracy effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

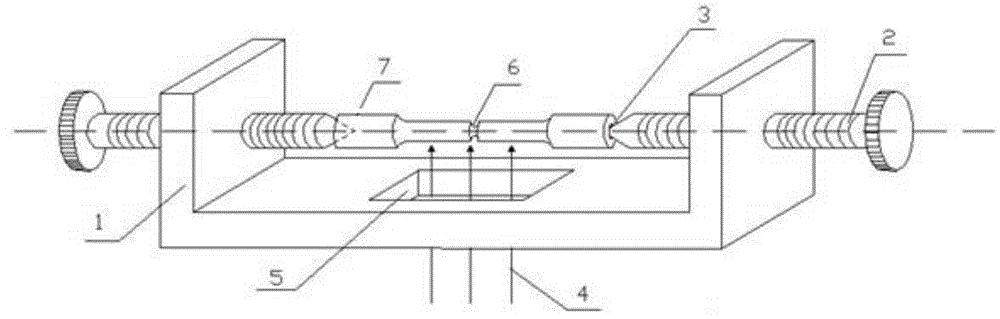

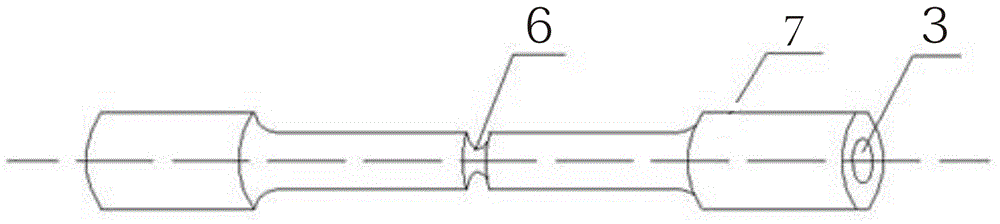

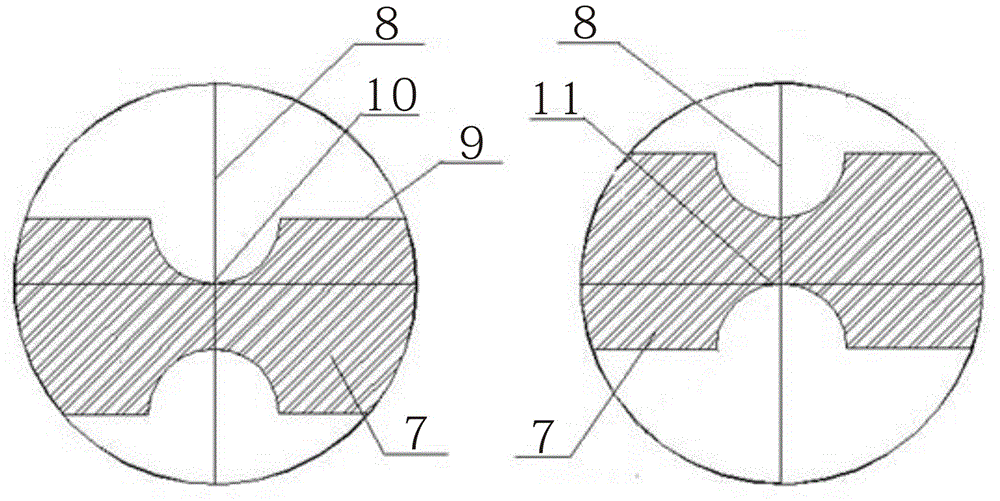

[0028] exist image 3 In the process, the sample fixing device is placed on the projector sample stage, the projection light 4 passes through the light hole 5, and the projection at the notch of the tensile sample 7 with a notched round rod can be seen on the screen of the projector, and the focal length is adjusted to make the image Clear, refer to the crosshair 8 of the projector, adjust the sample fixing device to adjust the image of the straight line section 9 of the sample to the level, rotate the micrometer head of the projector, make the upper diameter end 10 of the notch of the sample coincide with the horizontal line of the crosshair, and turn the projector display The value is cleared, continue to rotate the micrometer head of the projector, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com