Leakage detection method for central air conditioner copper tube

A technology for leak detection and central air conditioning, applied in the field of pipe leak detection, can solve the problems of large volume and difficult to balance pressure changes, and achieve the effects of accurate and reliable data, good stability, and convenient leak detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

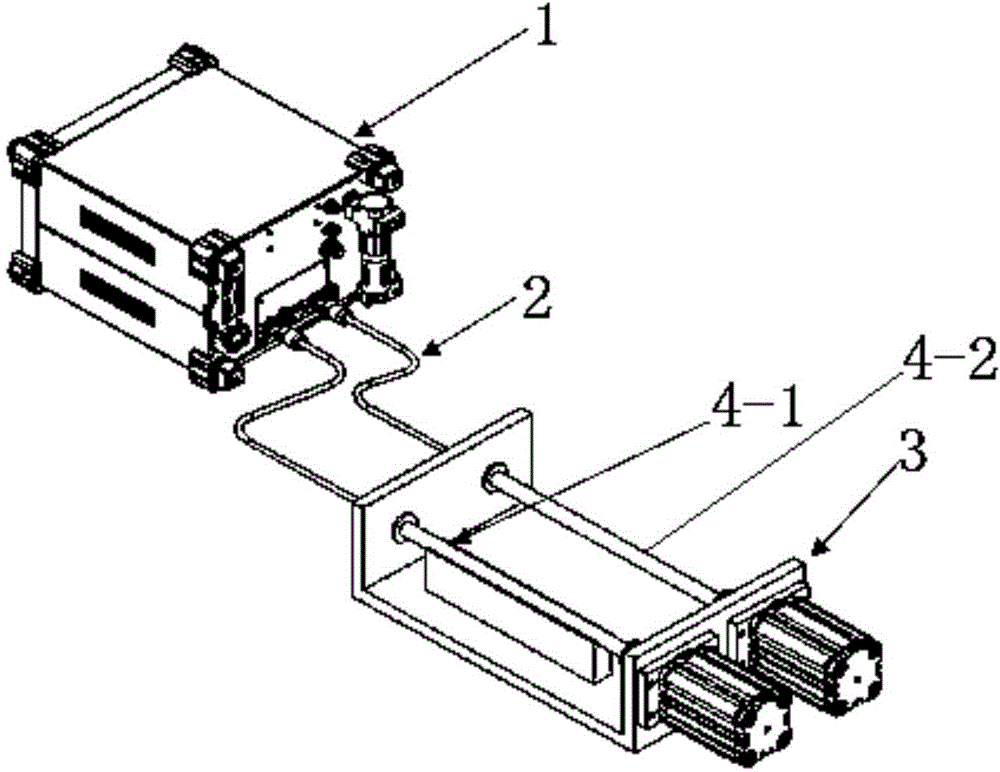

[0011] Such as figure 1 Shown. A leakage detection method for central air-conditioning copper pipes. A differential pressure airtight leak detector is used to counteract the background detection mode with double-ended symmetry. One end of the copper pipe to be tested is connected to the airtight leak detector through a pipeline. At the measuring end, one end of a low-leakage qualified copper pipe consistent with the volume, shape, and state of the copper pipe to be tested is connected to the standard end of the airtight leak detector through a pipeline. The low-leakage qualified copper pipe is used as a standard part. The gas inlet of the compressed air-tight leak detector is connected to high-pressure nitrogen or air, the other end of the tested copper pipe and the standard copper pipe is blocked by the plugging head, and then the tested copper pipe and the standard are tested by the air-tight leak detector. The copper pipes are tested in the process of inflation, pressure re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com