Testing apparatus and testing method for testing interlayer connection strength of pavement layers

A connection strength and testing device technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of the gap between the actual damage form and the theoretical simulation, the structure is heavy and complex, and the unified testing equipment has not been formed. Reasonable design and loading method to avoid tearing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

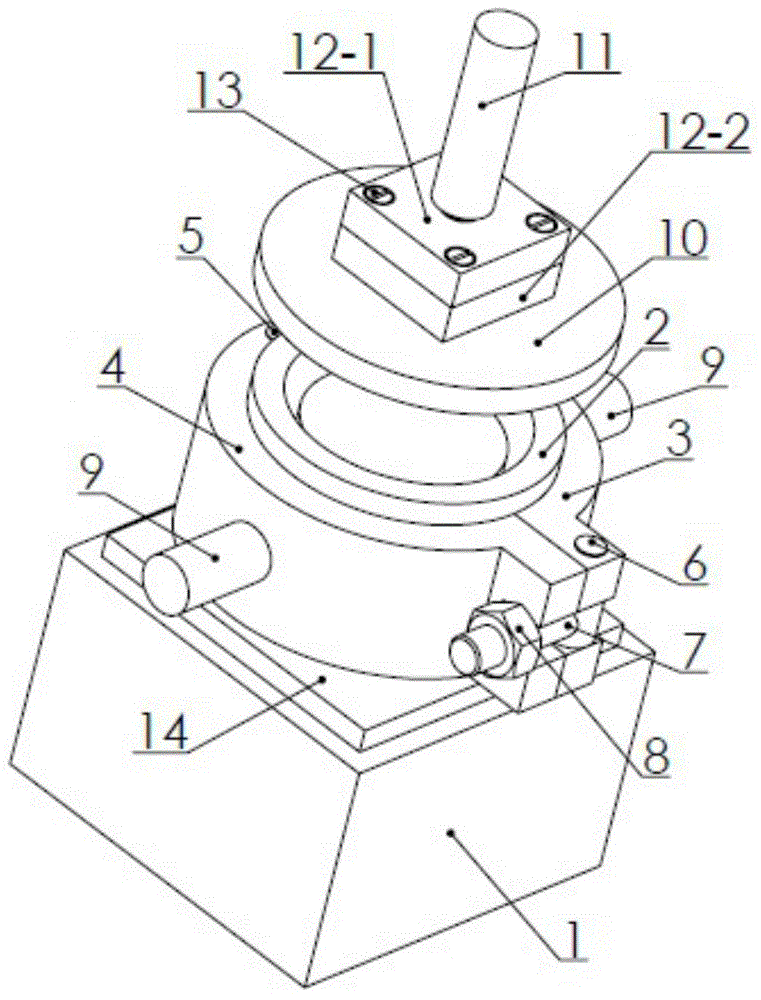

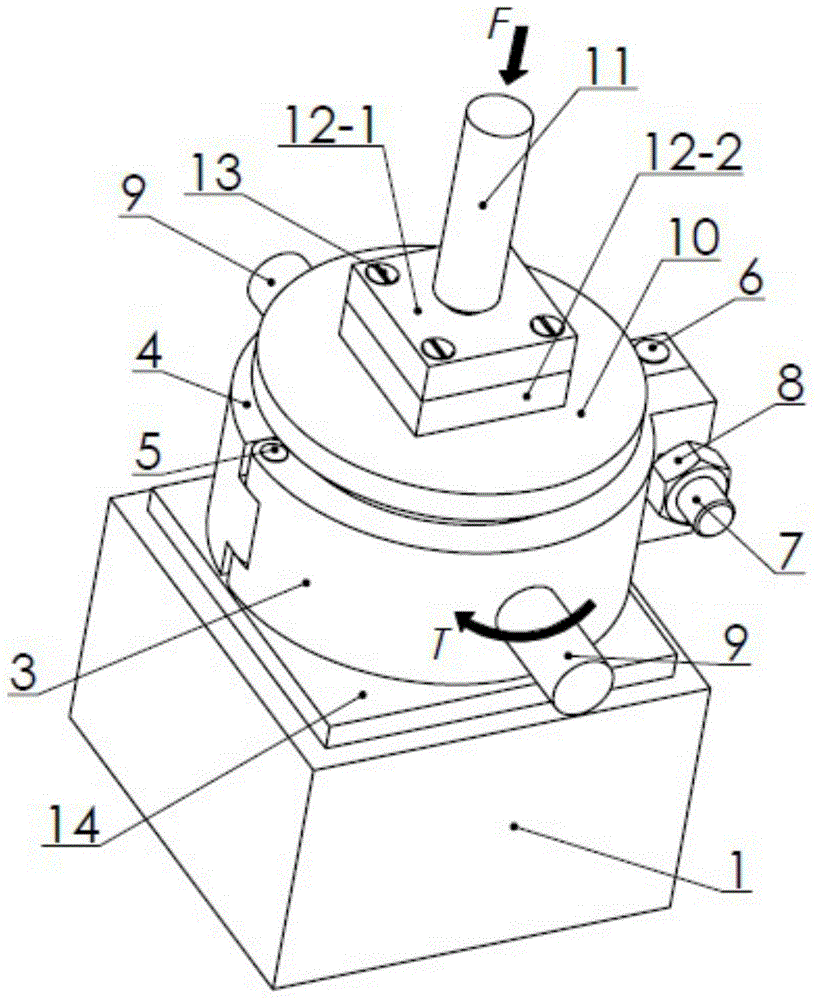

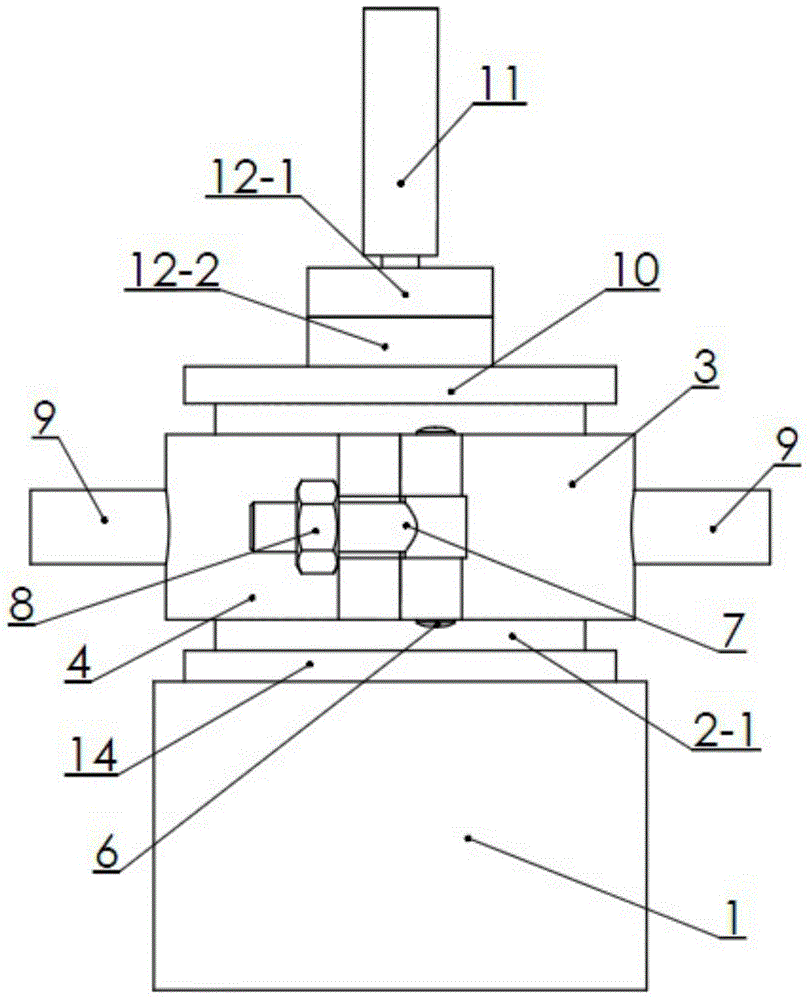

[0036] to combine figure 1 Figure 9 As shown, a test device for interlayer joint strength of pavement, including pavement sample, vertical pressure application device and torsional shear device. The vertical pressure application device is located above the pavement sample and the torsional shear device, and the vertical pressure application device applies vertical pressure to the pavement sample, such as figure 1 shown.

[0037] The vertical pressure applying device includes a push rod 11 and a top plate 10. The push rod is located above the top plate and is connected with the top plate. The upper part of the push rod is connected with a precision-controlled press, such as UTM-100, which provides accurate positive control for the vertical pressure applying device. Change to positive pressure. Specifically, the lower part of the push rod 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com