Detection method for chip defect

A detection method and chip defect technology, which is applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of low chip defect detection accuracy and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Such as Figure 5 , Figure 7-Figure 11 The detection method of chip defect shown:

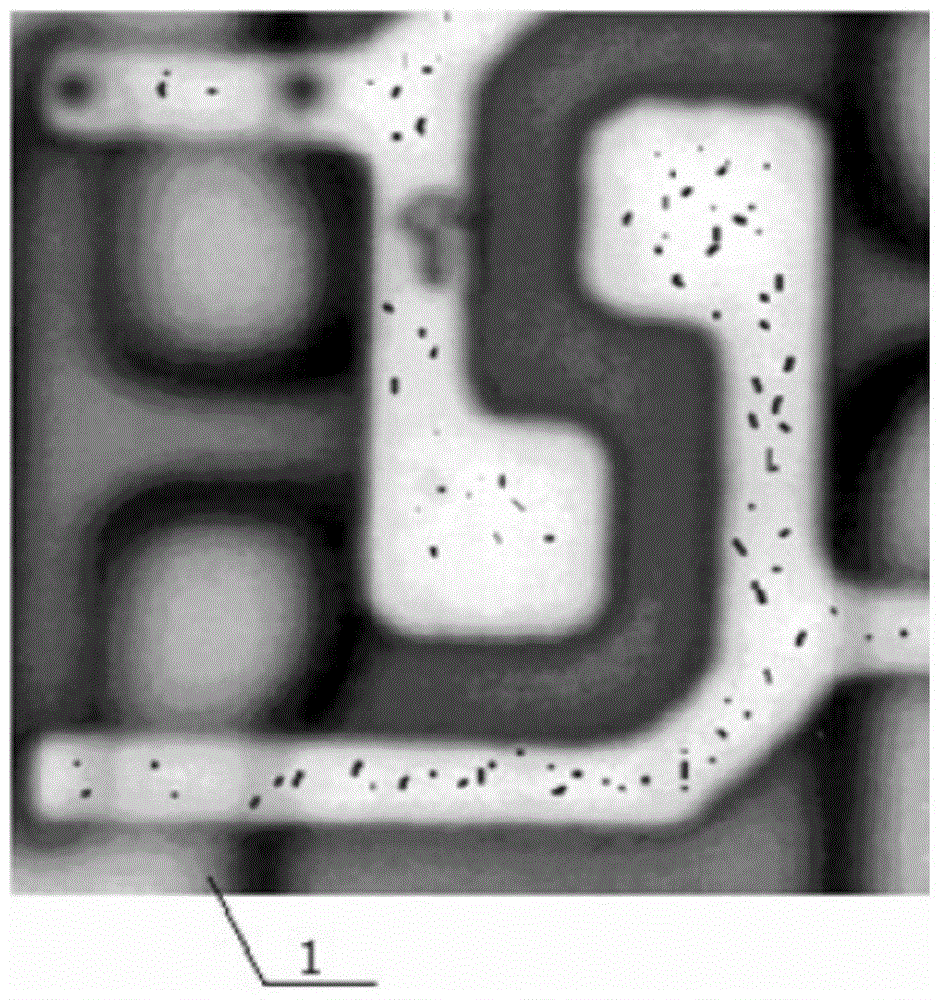

[0044] First provide a chipset and an optical inspection equipment, such as Figure 5 As shown, there are defects on the top and bottom of the chipset's circuit4, the optical inspection equipment is aimed at Figure 5 The defect 4 shown is tested;

[0045] Establish defect scanning procedures, for example Picture 9 The initial scan is set to the first focal length value above the circuit. When the optical detection device performs the initial scan, the first signal image of the chipset is collected, and the optical detection device converts the first signal image Is the first data image and stored in the database;

[0046] Right as Picture 10 The return scan shown is to set the second focal length value at the bottom of the circuit. When the optical detection device performs the return scan, the second signal image of the chipset is collected, and the second signal image is captured by the o...

Embodiment 2

[0050] Such as Picture 12 with 13 Shown: This embodiment is roughly the same as the first embodiment, and the specific improvement is as follows: Picture 12 As shown in the defect 4 located on the top and middle of the circuit, establish a scanning program for defect detection, set the first focus value on the circuit for the initial scan of the chip, and set the second focus on the middle of the circuit for the return scan of the chip Value, which can accurately detect defects above and in the middle of the circuit in the chip.

[0051] In the above two embodiments, the light detection device can set different focal lengths to perform multiple round-trip scans on the chip, and superimpose the two focal length data images of each round-trip scan, and combine the superimposed data image with the chip's Normal data images are compared, that is, multiple round-trip scanning is performed for multiple comparisons, so that defects in the chip can be detected more accurately.

[0052] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com