Flame-proof type double-loop feeder switch for mine

A feed switch and double-loop technology, applied in the field of feed switches, can solve the problems that the feed switch technology cannot meet the actual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

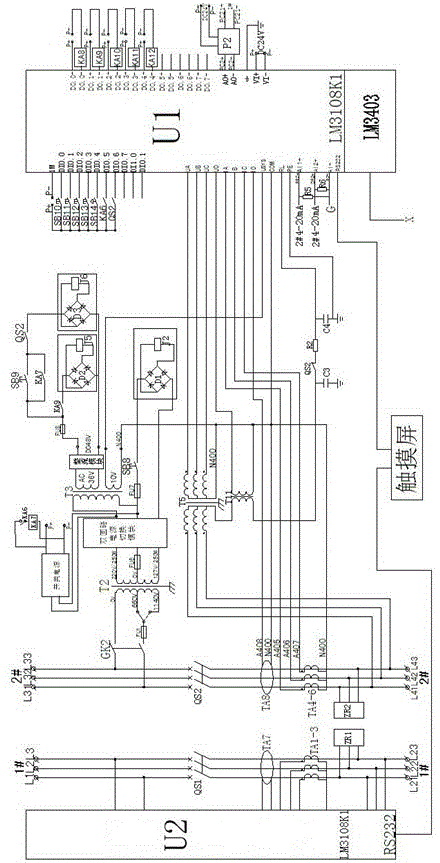

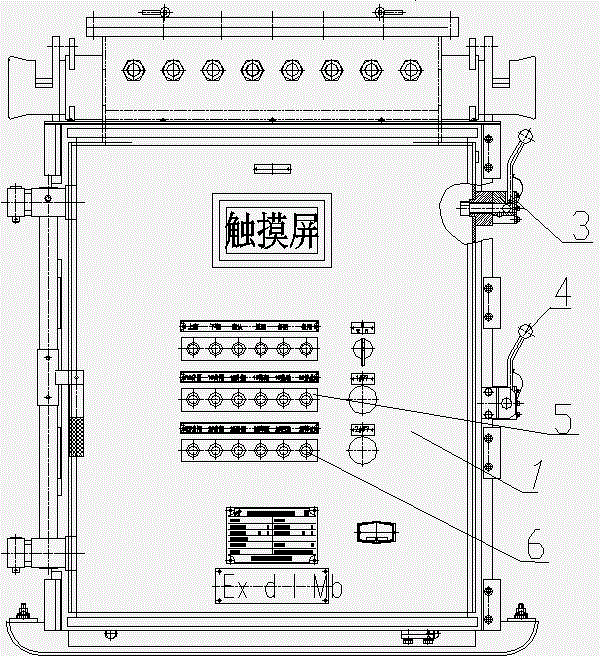

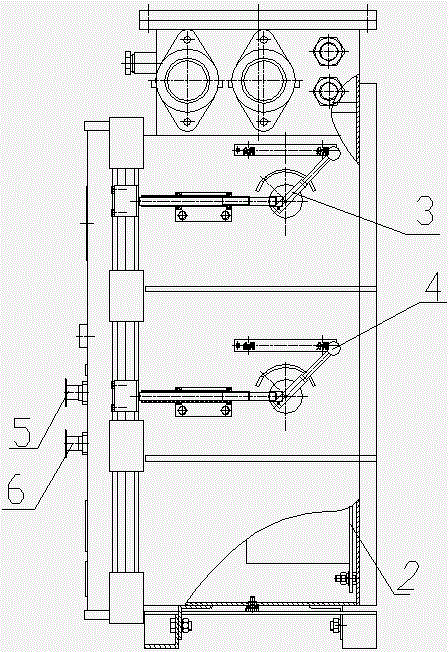

[0019] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a flameproof enclosure, and the flameproof enclosure includes a main cavity 1 and a wiring cavity 2. The main cavity 1 is provided with a core frame and a double-circuit feed switch circuit board, and the side of the main cavity 1 is provided with a main transfer switch 3 and The sub-transfer switch 4, multiple wiring outlets are set on the wiring chamber 2; the number 5 in the figure is the manual button for controlling the operation of multiple loads in the main feed switch circuit, and the number 6 in the figure is the operation control button for multiple loads in the secondary feed switch circuit Manual button. The double-loop feed switch circuit board includes a main feed switch circuit, a secondary feed switch circuit and a dual-circuit power switching module, and the main feed switch circuit includes a main transfer switch QS2, a first signal acquisition circuit, and a first cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com