Blade, particularly variable-pitch blade, propellor comprising such blades and corresponding turbomachine

A propeller and variable pitch technology, which is applied in the direction of propellers, mechanical equipment, aircraft parts, etc., can solve the problems of unstable propeller speed, damage to the aerodynamic performance of downstream propellers, and aggravate turbulent flow activities at the base of propeller blades, so as to reduce the intensity of noise, The effect of promoting performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

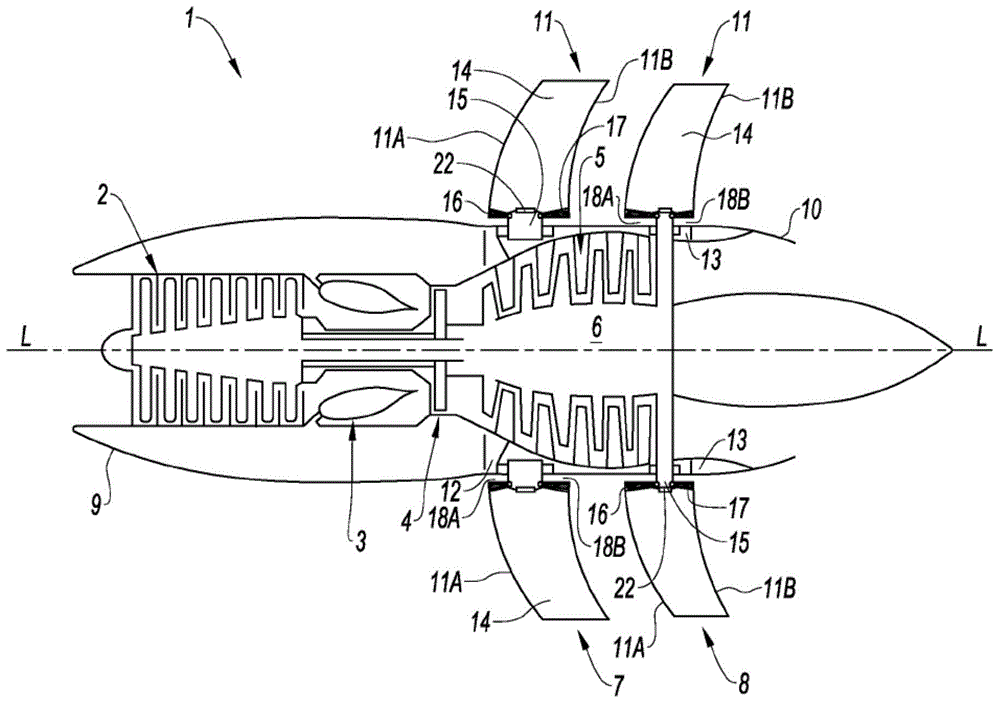

[0036] figure 1 Shown is an unducted fan turbine engine 1 according to the invention comprising a compressor 2, an annular combustion chamber 3, a high pressure turbine 4 and The two counter-rotating low-pressure turbines 5 and 6 , that is to say the low-pressure turbines 5 and 6 rotate about the longitudinal axis L-L in two opposite directions.

[0037] Each low-pressure turbine 5 and 6 is connected in a rotationally fixed manner to external propellers 7, 8 which extend radially to the outside of the nacelle 9 of the turbine engine 1, the nacelle 9 having a generally cylindrical shape surrounding the compressor 2, the combustion chamber 3 and turbines 4, 5 and 6 extend along the axis L-L. Combustion gases leaving the turbine are expelled via nozzle 10 to increase thrust.

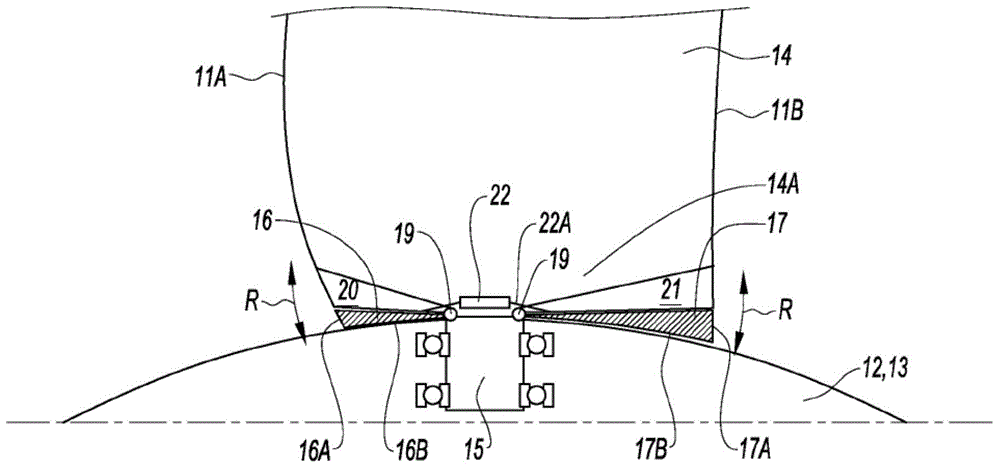

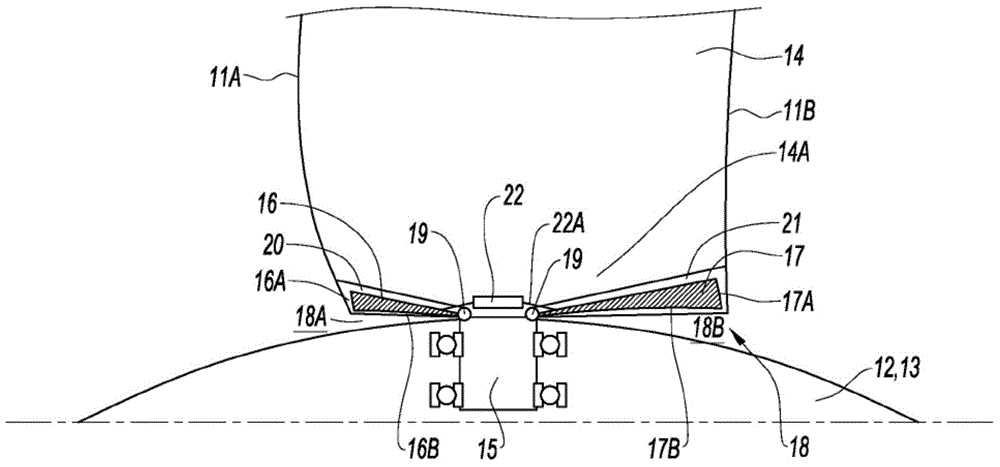

[0038] The propellers 7 and 8 are coaxially arranged one behind the other and comprise a plurality of blades 11 equiangularly distributed around the longitudinal axis L-L. The blades 11 extend generally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com