Method and nozzle arrangement for introducing chemicals and/or additives into a process flow of a production process

A manufacturing process, chemical technology, applied in chemical instruments and methods, chemical/physical process, pulp raw material addition process, etc., can solve problems such as unattainable flow speed, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

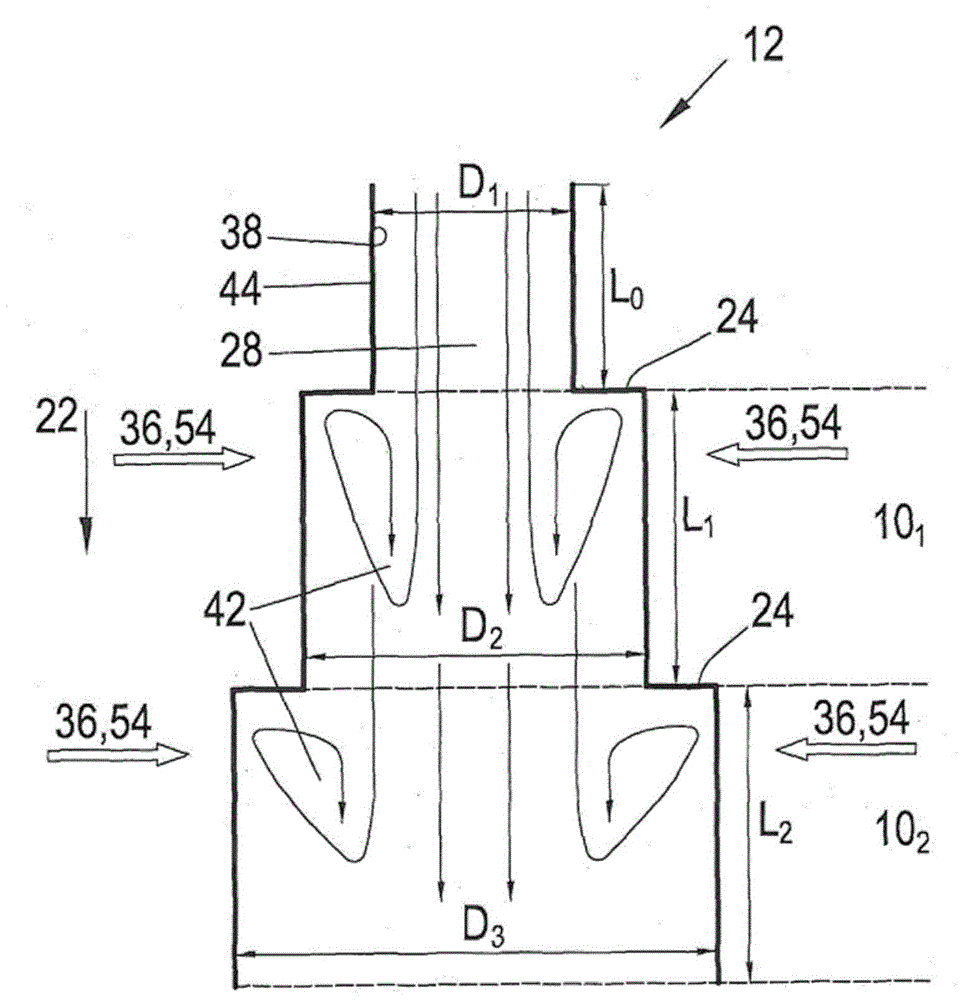

[0072] figure 1 A process stream 16 for introducing chemicals and / or additives into a manufacturing process according to the invention is shown in a schematic illustration (see also Figure 6 to Figure 8 ) of an exemplary embodiment of the nozzle device 14 comprising a plurality of mixing and / or reaction zones 10 1 、10 2 The base part 12 of , wherein the manufacturing process can be especially a process for manufacturing paper fibers or nonwoven fibers. Here, individual mixing and / or reaction zones 10 can be 1 、10 2 At least two media 28, 54 are provided to be mixed and / or chemically reacted with each other.

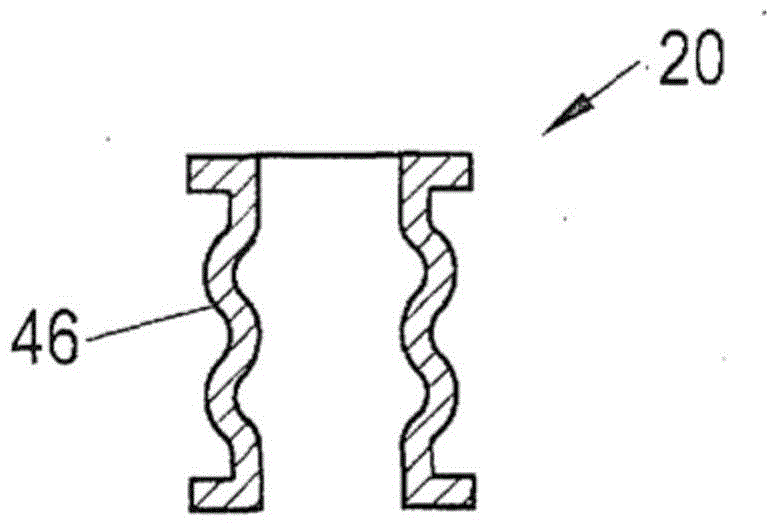

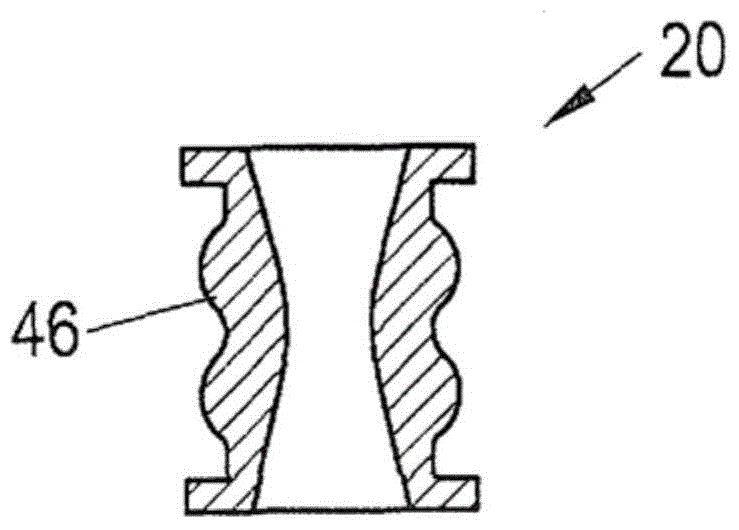

[0073] as from Figure 6 to Figure 8 As is known in the art, the nozzle arrangement 14 may comprise a throttle device 20 arranged in the region of the nozzle outlet 18 .

[0074] In this case, the nozzle arrangement 14 comprises, for example, two mixing and / or reaction zones 10 arranged one behind the other when viewed in the main flow direction 22 1 、10 2 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com