Method for producing and manufacturing polycrystalline silicon after recycling and reusing tail gas of polycrystalline silicon reducing furnace by using improved Siemens process

A Siemens method and polysilicon technology, applied in the field of polysilicon production, can solve problems such as limitations, high energy consumption, and low conversion efficiency, and achieve the effects of saving production time, increasing polysilicon yield, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

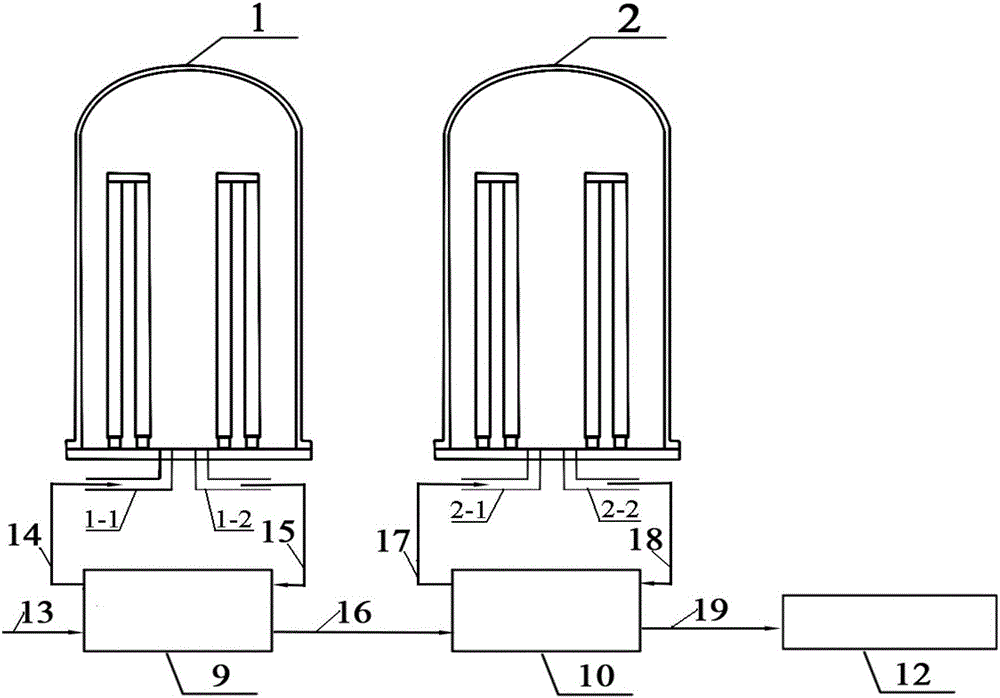

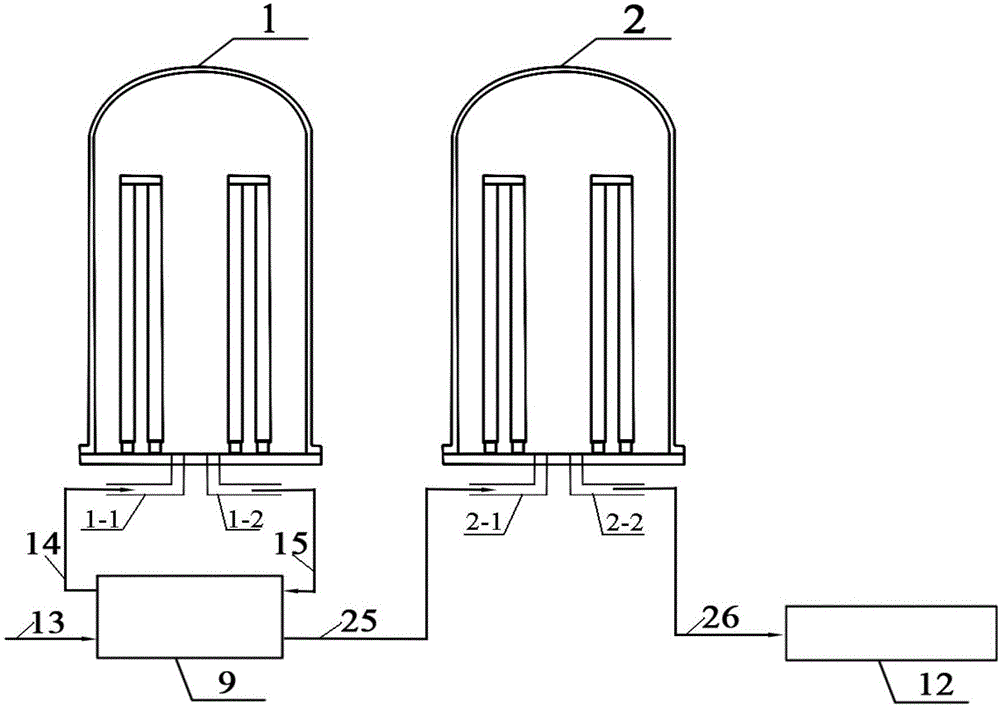

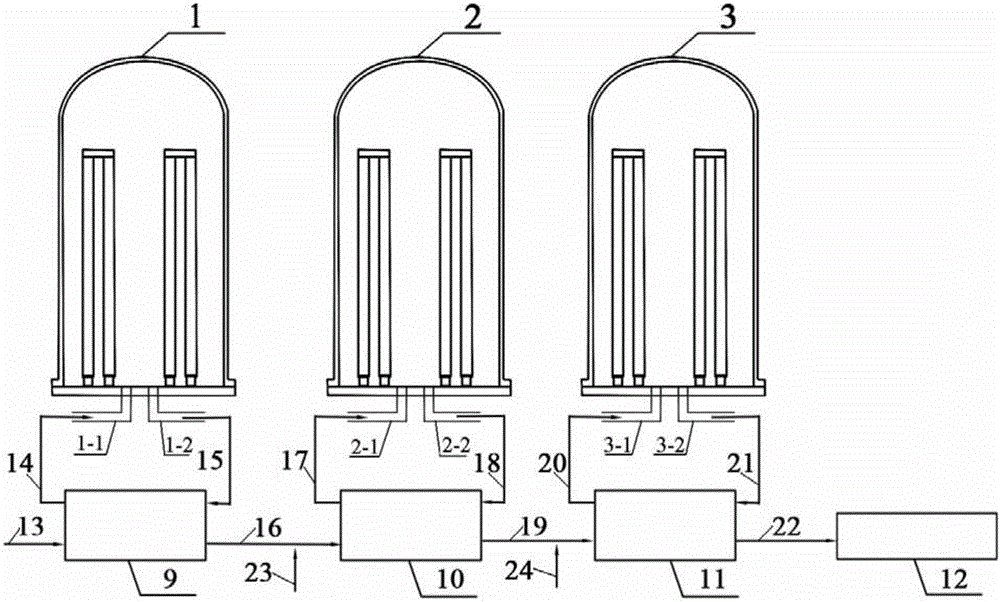

[0021] Specific implementation mode one: this embodiment is the method for producing polysilicon after the exhaust gas of the improved Siemens method polysilicon reduction furnace is recycled and reused. In addition to one improved Siemens method polysilicon reduction furnace equipment, use gas pipelines to connect the tail gas outlet of each improved Siemens method polysilicon reduction furnace equipment to the intake inlet of the next improved Siemens method polysilicon reduction furnace equipment, and connect them in turn, and Install flow meters and flow control valves on each gas pipeline to obtain series equipment; the intake inlet of the first improved Siemens method polysilicon reduction furnace equipment that feeds the raw material gas into the series equipment, and the improved Siemens method polysilicon reduction furnace equipment chassis The uniformly distributed nozzle structure on the surface is sprayed into the reduction chamber of the improved Siemens method pol...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the silicon cores used in the multiple improved Siemens method polysilicon reduction furnaces are round silicon cores or square silicon cores. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and one of specific embodiments one or two is that the raw material gas is a mixed gas of trichlorosilane, dichlorodihydrosilane and hydrogen, wherein hydrogen and trichlorohydrogen The molar ratio of silicon is (2-4):1, and the mass percentage of dichlorodihydrosilane in the total mass of trichlorosilane and dichlorodihydrosilane is 4%-6%. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com