Chemical spraying device for sewage treatment

A technology for sewage treatment and sewage, which is applied in the directions of water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of low purification efficiency, large space occupation, and large equipment occupation space, etc. , to achieve the effect of enhancing the mixing effect, improving the effect and increasing the flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

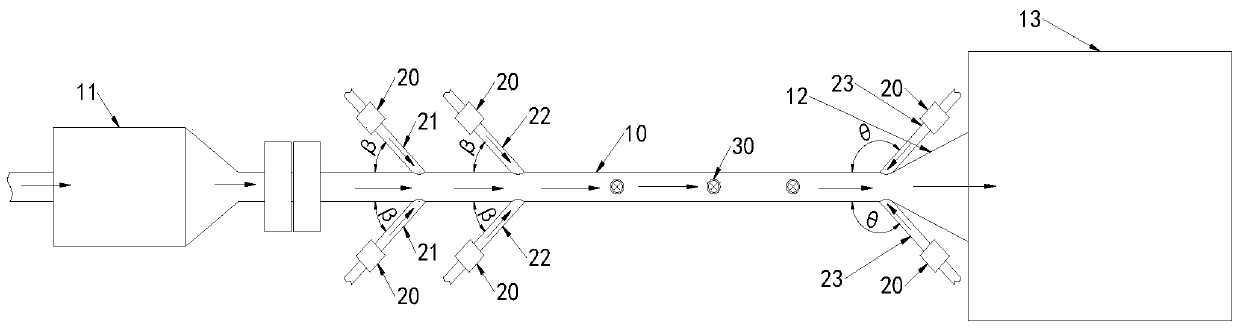

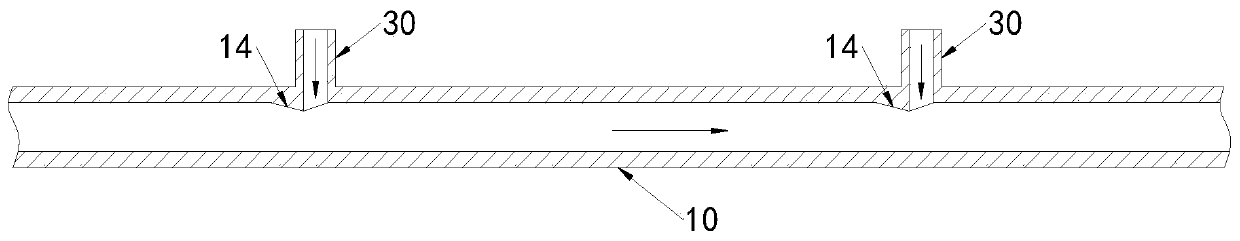

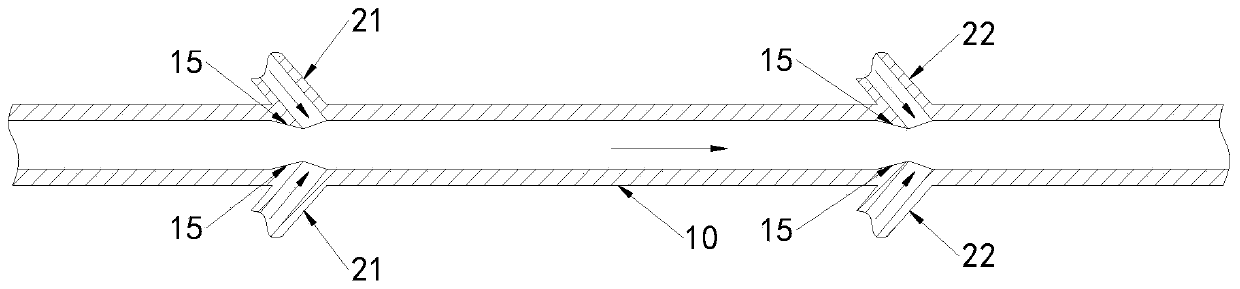

[0022] like figure 1 As shown, the present embodiment provides a spraying device for sewage treatment, which device includes: a sewage pipe 10 provided with a jet 11, a spray pipe with a supercharger 20 installed, and an aeration pipe 30; the jet 11 is installed at the front end of the sewage pipe 10, the spraying pipe is connected to the side walls on both sides of the sewage pipe 10, the aeration pipe 30 is connected to the top side wall of the sewage pipe 10, and the spraying pipe The connection between the pipe and the sewage pipe 10 is located at the front end of the connection between the aeration pipe 30 and the sewage pipe 10, and the sewage in the sewage pipe 10 passes through the aeration pipe at high speed after being jetted by the jet device 11. The pipe 30 generates negative pressure, sucks the air from the aeration pipe 30 into the sewage pipe 10 and mixes it with the sewage to realize the aeration of the sewage. Such a device can realize the aeration of the sewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com