Valve arrangement for hermetic compressors

A valve device and compressor technology, applied in valve devices, components of pumping devices for elastic fluids, control valves, etc., can solve problems such as reducing reliability and increasing impact force, reducing stress, viscosity, etc. The effect of reducing the attached area and reducing the adhesion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will describe a hermetic compressor for use in a refrigeration system, such as a domestic or commercial refrigeration system of the type previously described.

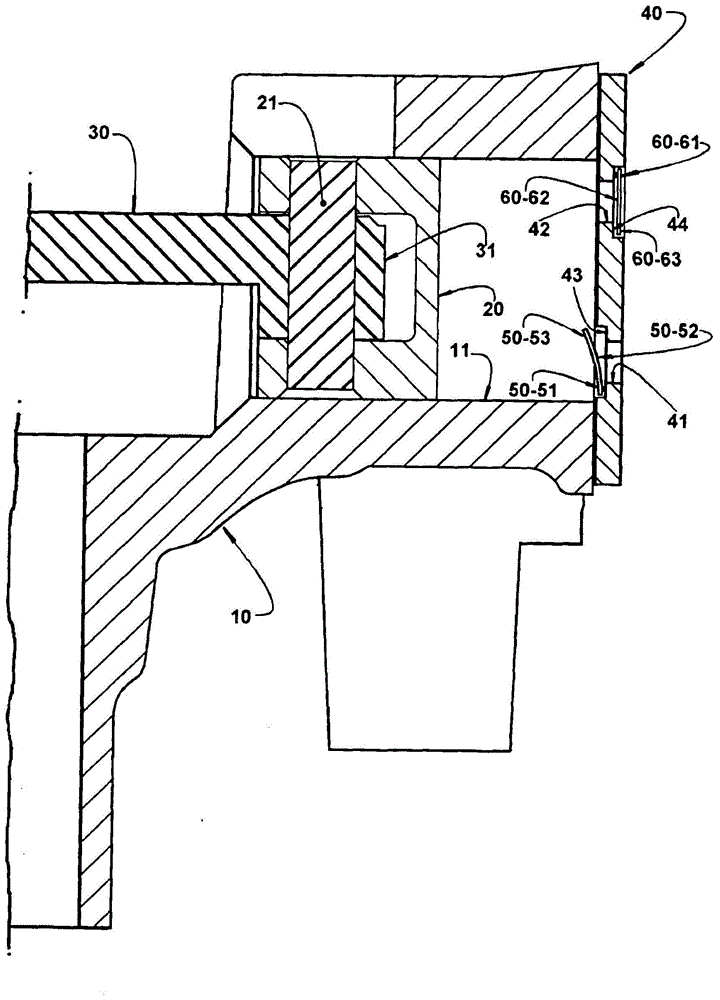

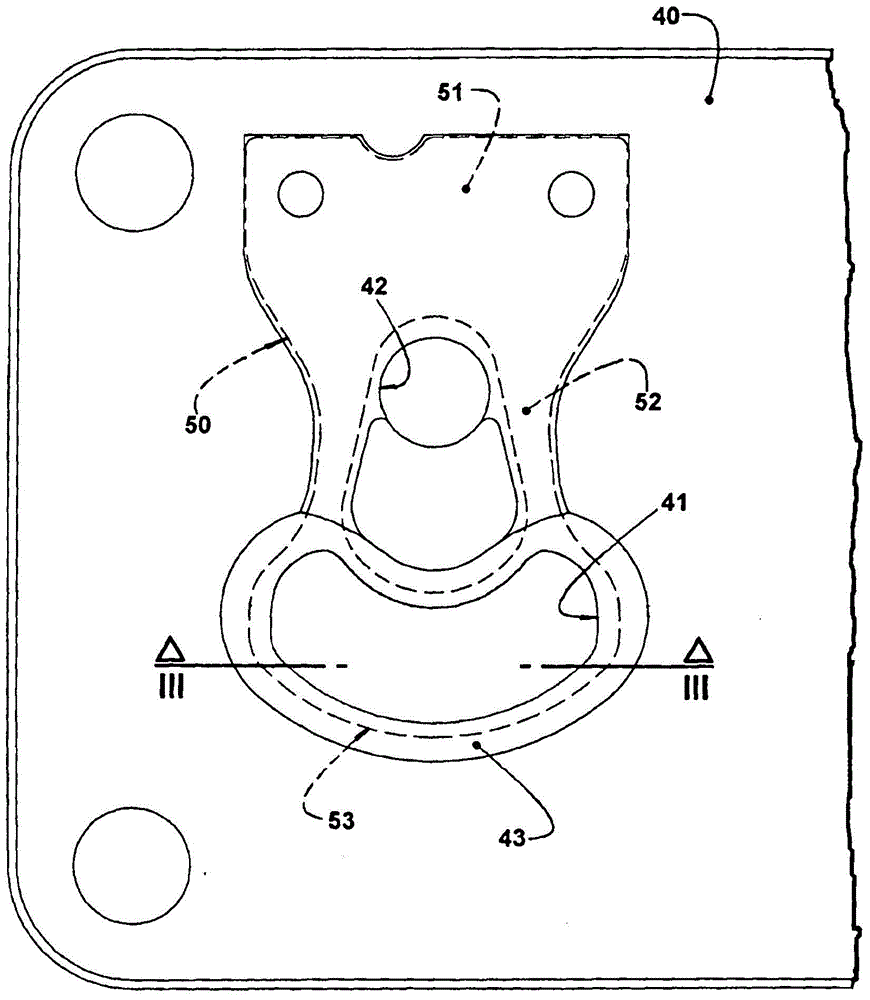

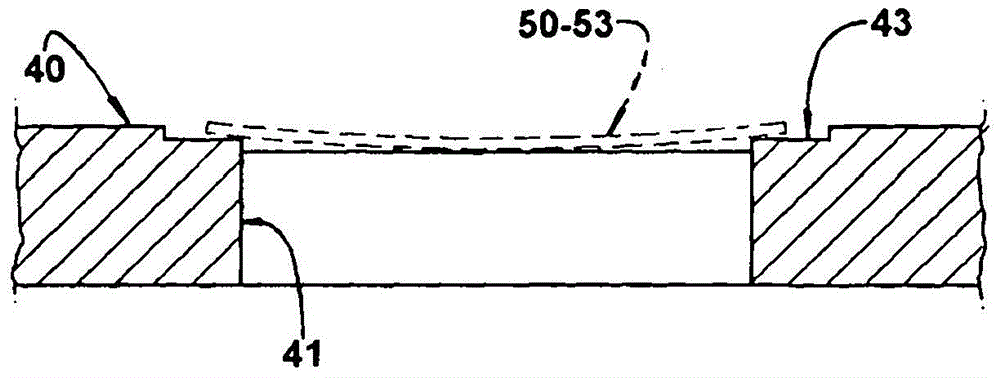

[0038] The hermetic compressor comprises: a cylinder crankcase 10 defining a compression cylinder 11; a valve plate 40 which closes one end of the compression cylinder 11 and is provided with a suction hole 41 and a discharge hole 42 and their respective seating areas 43, 44, each of said Both the suction hole 41 and the discharge hole 42 are closed by respective valve suction vanes 50 and valve discharge vanes 60 .

[0039] Each suction vane 50 and each discharge vane 60 has: a mounting end 51, 61 for attachment to the valve plate 40; a curved central portion 52, 62; The associated sealing ends 53, 63 and are displaced by elastic deformation between a valve-closed position blocking the passage of gas through the respective suction orifice 41 and discharge orifice 42, and a valve-opening po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com