Paint spraying processing device for water paint VOC gas

A technology for processing equipment and water-based paint, applied in spraying devices, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of no VOC, low VOC content, high VOC content, etc., to improve safety and ensure harmlessness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

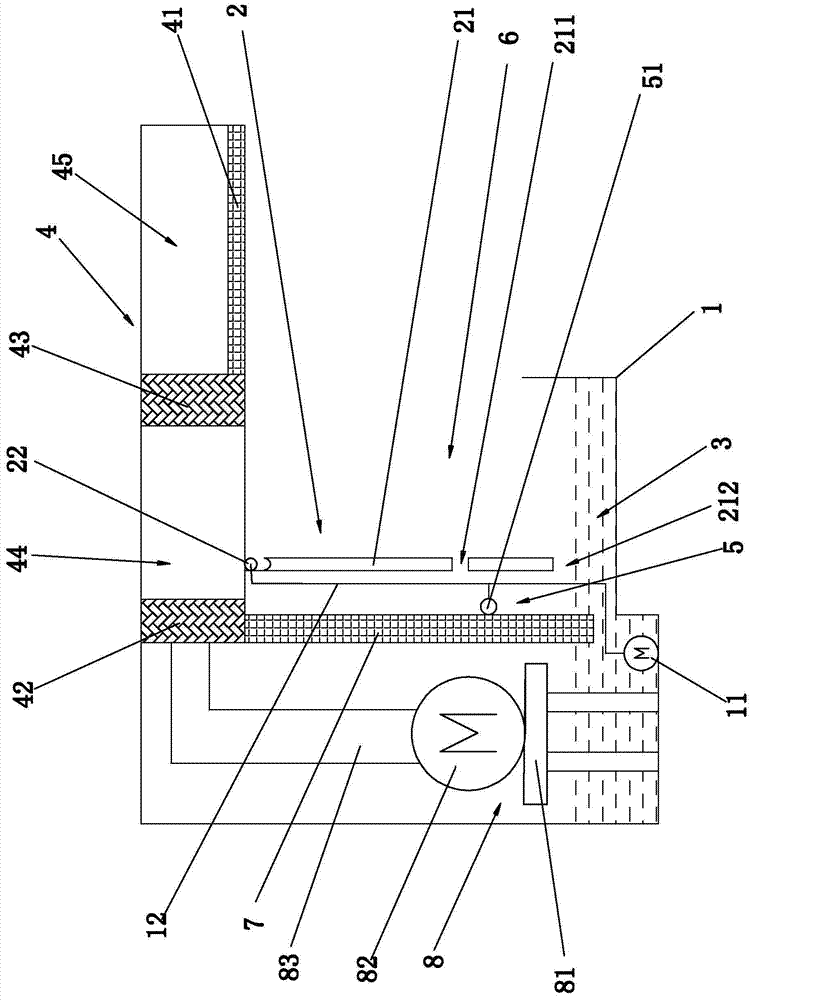

[0020] Such as figure 1 As shown, the embodiment of the present invention is specifically a kind of spray paint treatment equipment of water-based paint VOC gas, comprising a water tank 1 and a spray device 2, water 3 is provided in the water tank 1, and an air supply chamber 4 is provided above the water tank 1, and the spray The shower device 2 is arranged between the air supply chamber 4 and the water tank 1 . The spraying device 2 includes a water curtain plate 21 and a water shower head 22 arranged on the top of the water curtain plate 21. The water curtain plate 21 is provided with a water mist suction port 211, and the water mist suction port 211 is arranged in the middle of the water curtain plate 21. . The water mist suction port 211 communicates with spaces on both sides of the water curtain plate 21 . One side of the water curtain plate 21 is provided with a water mist chamber 5 . An atomizing nozzle 51 is arranged in the water mist chamber 5 . The side of the w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap