Cantilevered moving and rotating belt conveying and distributing machine and work assigning method

A belt conveyor and distributor technology, applied in the field of yard machinery, can solve the problems of inability to achieve continuous production, limited stacking range, and high equipment damage rate, so as to overcome the shortcomings of secondary loading and unloading, improve production efficiency, and occupy less space. Small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

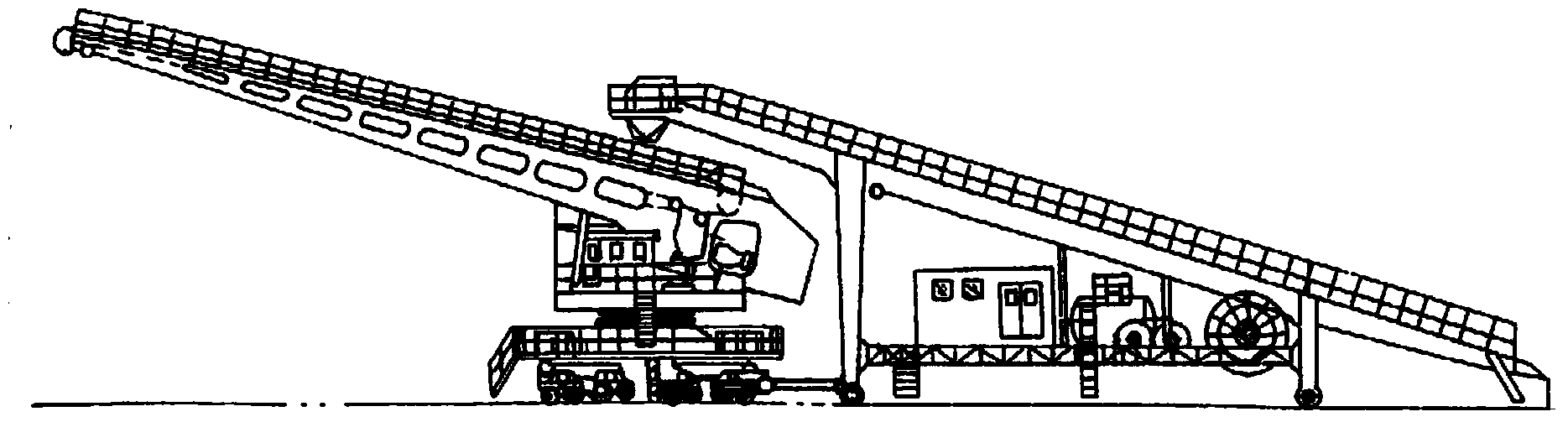

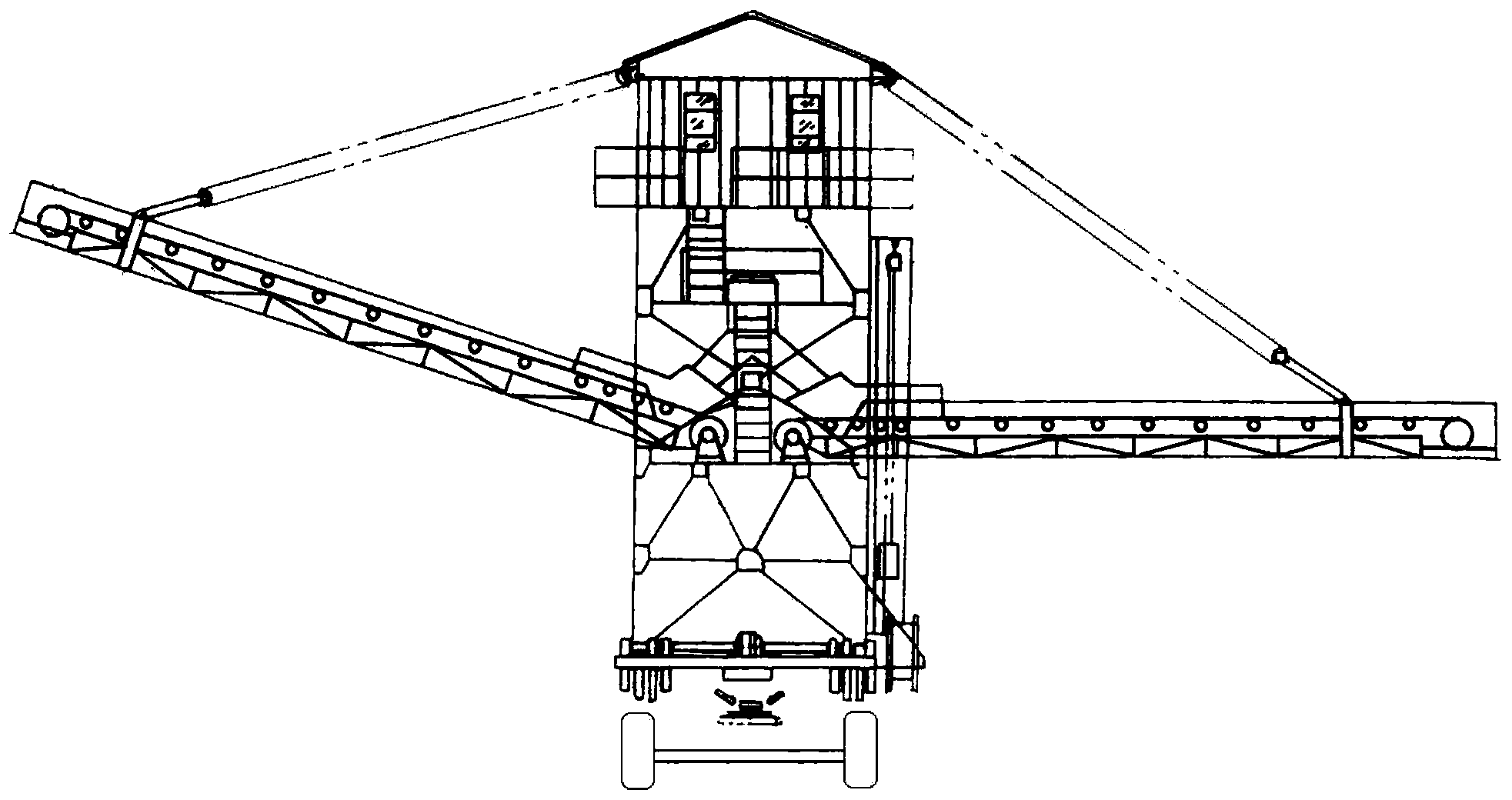

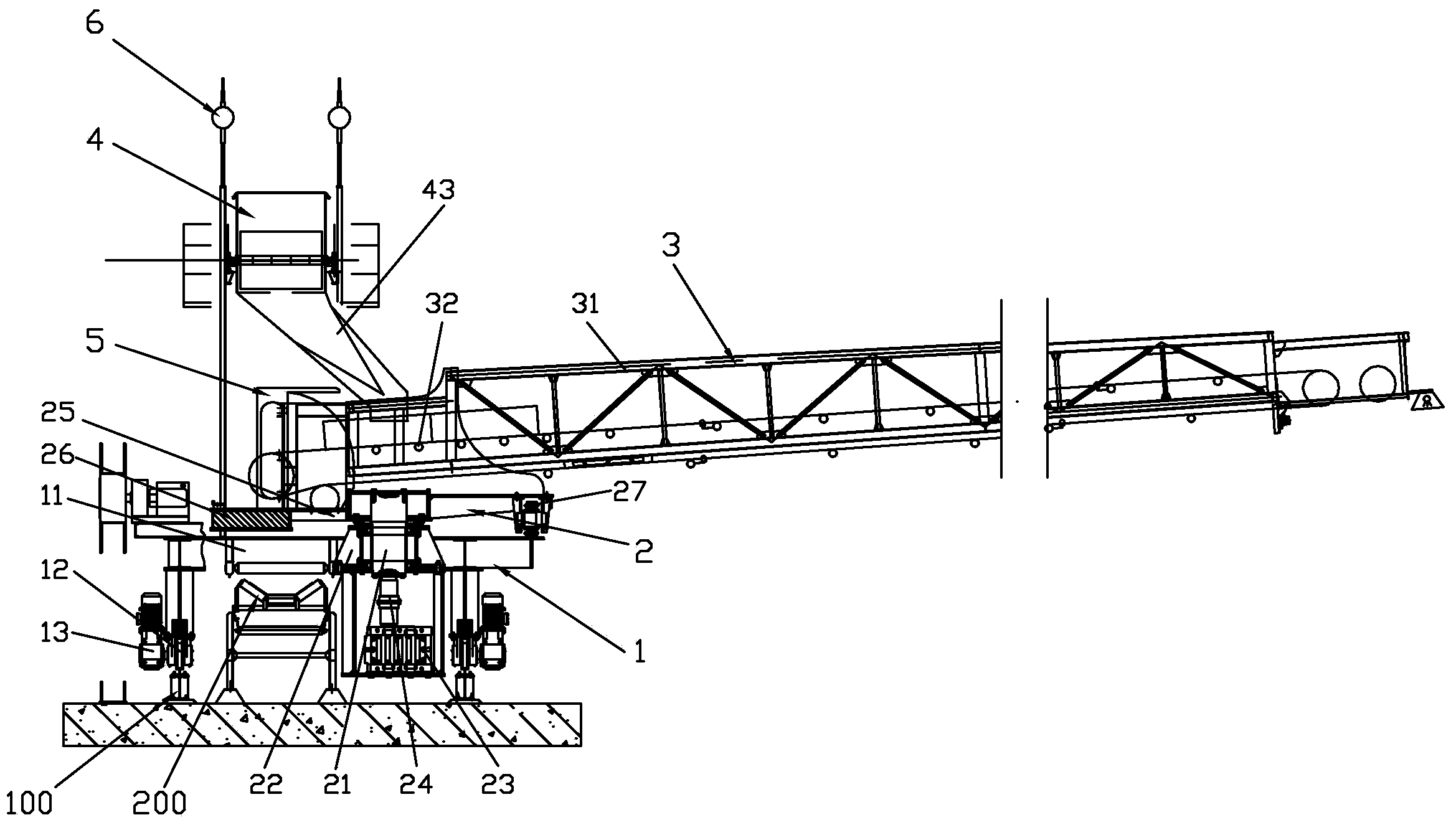

[0038] see Figure 3 to Figure 9 , a cantilever-type mobile rotary belt-type conveying distribution machine of the present invention, which includes a running mechanism 1, including a mobile platform 11, under which wheels 12 and corresponding geared motor drive devices 13 are arranged, so as to travel on the track 100; The slewing mechanism 2 includes a rotating shaft 21, which is vertically arranged on one side of the moving platform 11 of the traveling mechanism 1 through a bearing seat 22; a motor+reducer combination 23, which is arranged below the moving platform 11 with the rotating shaft 21 , the output shaft of the reducer is connected to the rotating shaft 21 through a coupling 24; the rotary platform 25, one end of which is connected to the upper end of the rotating shaft 21, is driven by the rotating shaft 21 to realize rotation; the material distribution mechanism 3 includes, cantilever, steel structure truss Form 31, one end of the cantilever is fixed on the rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com