Horizontal folding mechanism of folding machine

A stacking machine and horizontal folding technology, which is applied in the direction of folding thin materials, sending objects, thin material processing, etc., can solve the problems of folding edge compaction, false creases, troublesome manual operation, etc., and achieve strict consistency of folding width, Prevents paper jams and neatly folds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the examples, but not limited thereto.

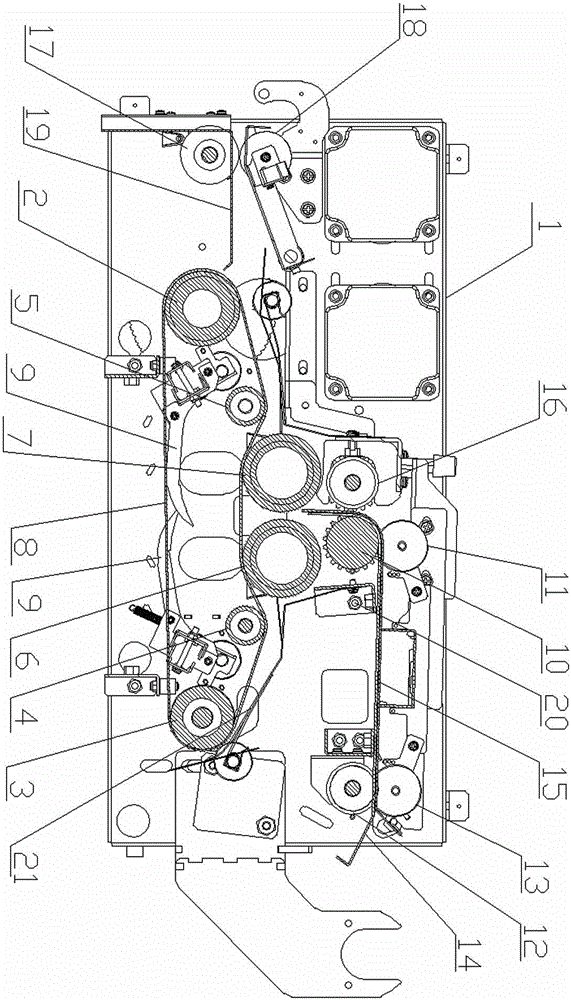

[0028] Such as figure 1 As shown, the horizontal folding mechanism of the folding machine of the present invention includes a base 1, a driving rubber roller 2, a tensioning auxiliary shaft 3, an auxiliary front shaft 4, an auxiliary rear shaft 5, a front auxiliary shaft 6, a rear auxiliary shaft 7, and a belt 8 , paper-pushing claw 9, paper feed main roller 10, paper feed main roller press wheel 11, paper feed shaft 12, paper feed shaft press wheel 13, lower guide plate 14, upper guide plate 15 located on the upper part of lower guide plate 14, feed Paper conveying auxiliary shaft 16, paper output driving shaft 17, paper output driving shaft pressure wheel 18, paper receiving table 19, sensor 20, paper lowering guide plate 21.

[0029] The active rubber roller 2 and the tensioning auxiliary shaft 3, the auxiliary front shaft 4 and the auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com