Oil supply control method, device and system of hoisting mechanism hydraulic system and crane

A technology of a hydraulic system and a hoisting mechanism, which is applied in the oil replenishment control of the hydraulic system and the field of hoisting machinery, can solve the problems of hidden safety hazards and the inability to realize the oil replenishment of the high pressure chamber, and achieve the effect of improving safety and reducing hidden safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

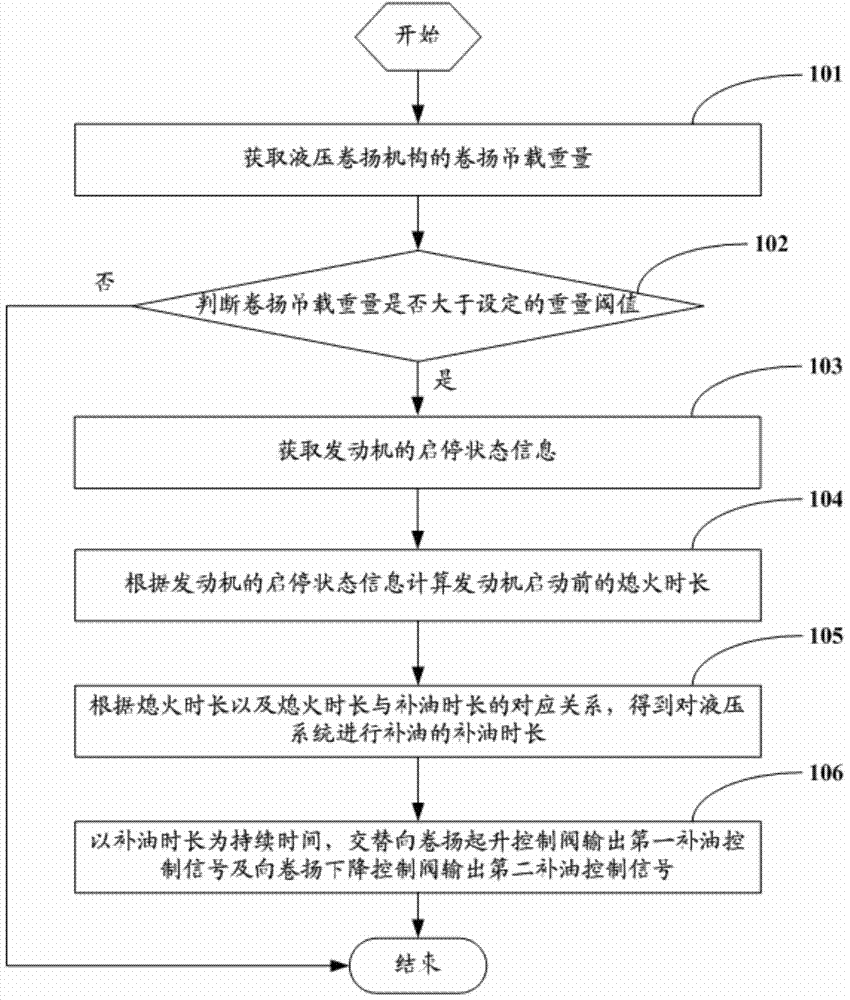

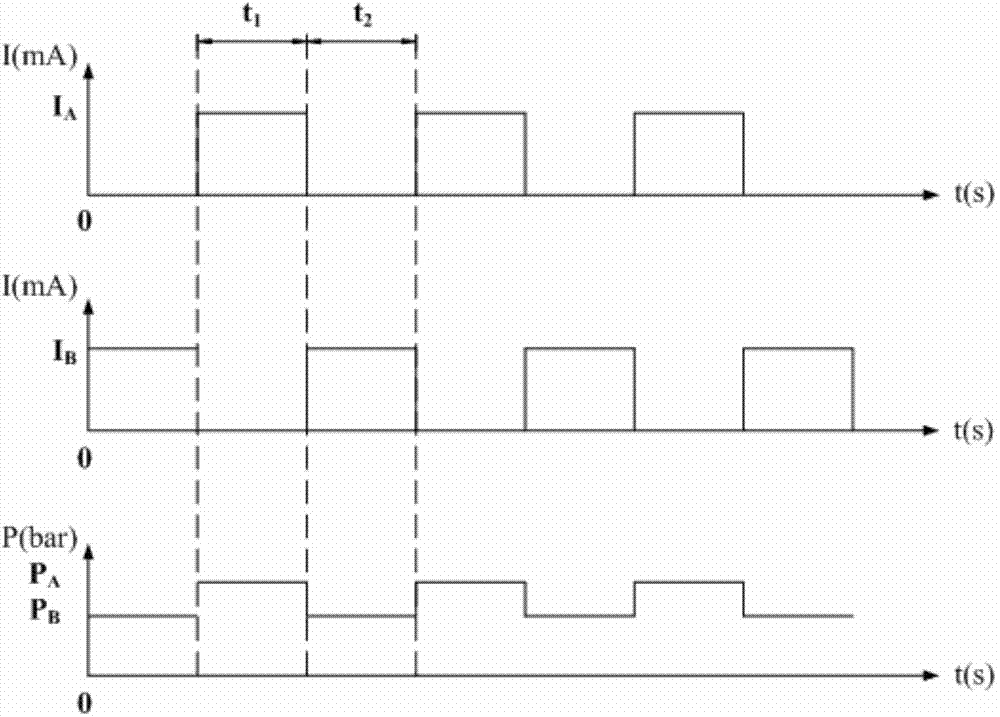

[0041] In order to improve the safety of hoisting and landing operations of a crane, embodiments of the present invention provide a method, device, and system for oil replenishment control of a hydraulic system of a hydraulic hoisting mechanism and a crane. In this technical solution, the corresponding relationship between the flameout duration and the fuel replenishment duration is obtained through accurate analysis or experimental statistics and stored in the control device. When the hoisting weight is greater than the set weight threshold, according to the flameout time and the corresponding relationship between the flameout time and the oil replenishment time, the oil replenishment time for the hydraulic system is obtained. The determination of the oil replenishment time is more objective and accurate , and within the oil replenishment time, alternately output the first oil replenishment control signal to the winch lifting control valve and output the second oil replenishme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com