Low-viscosity easy-to-pump ultrahigh-strength concrete with average strength of 120MPa

A technology of ultra-high-strength concrete and average strength, which is applied in the field of building materials and can solve the problems of difficult pumping, high viscosity, and inability to use ultra-high-strength concrete for pumping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

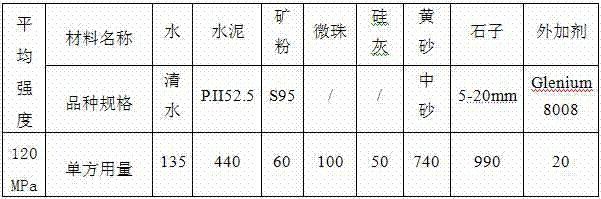

[0026] Below we will further elaborate on the low-viscosity, easy-to-pump concrete with an average strength of 120 MPa in conjunction with specific examples, in order to understand its structural fit and functional characteristics more clearly, but it cannot be used to limit it. protected range.

[0027] The invention is a low-viscosity, easy-to-pump superhigh-strength concrete with an average strength of 120MPa. The concrete includes cement, slag micropowder, microbeads, silica fume, sand, stones, admixtures and water.

[0028] One of the most important components and proportions are as follows:

[0029] Composition unilateral dosage ratio (kg / m 3 )

[0030] Cement 400~440

[0031] Silica fume 40~60

[0032] Slag fine powder 60~80

[0033] Microbeads 100~120

[0034] Natural sand with a fineness modulus of 2.8-3.2 700-750

[0035] Pebbles 980~1000

[0036] Admixture 19.5~22.75

[0037] Mix water 130~135.

[0038] The present invention is used for ultra-high-strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com