Confined steel plate structure and construction method of a super high-rise steel plate concrete shear wall

A steel plate shear wall and concrete shear wall technology, which is applied to building structures, walls, building components, etc., can solve the problems of difficult and precise control of the installation position, large deformation of the steel plate shear wall, and inability to adjust the position after connection, etc. To achieve the effect of easy and precise control of the installation position, saving construction costs and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

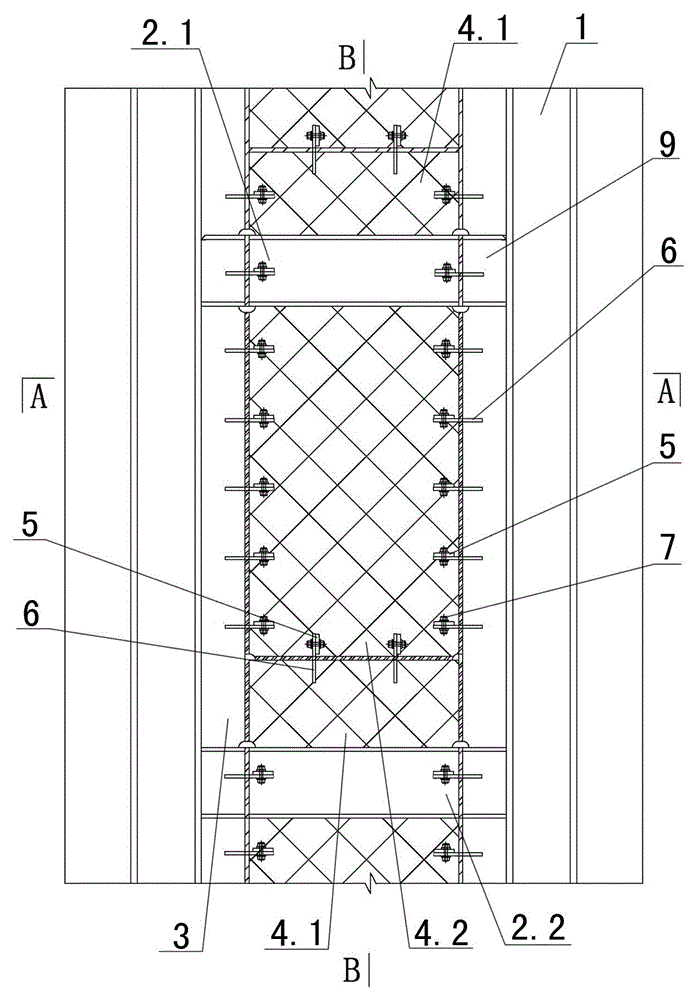

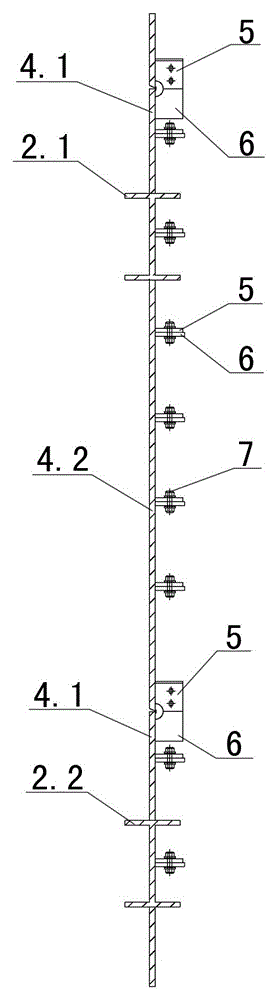

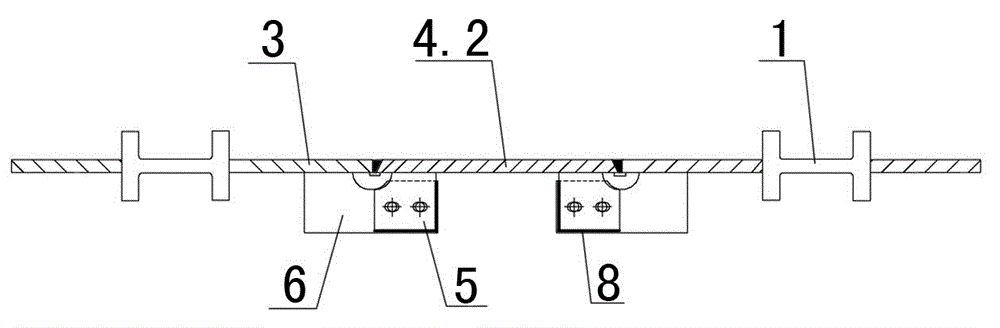

[0033] see example Figure 1-3 As shown in the figure, a constraining steel plate structure of a super high-rise steel plate concrete shear wall includes an outer edge member, a steel plate shear wall 4 connected with the outer edge member, and a constraint connection unit between the two, and the constraint connection unit includes an upper and lower A constraining sub-plate 5 and a constraining mother plate 6 that correspond and cooperate with each other. The constraining sub-plates 5 are arranged at intervals along the inner side of the steel plate shear wall 4, and are perpendicular to the steel plate shear wall. The mother board 6 is arranged at intervals along the inner side of the outer edge member and is perpendicular to the outer edge member, the component size of the restraint sub-board 5 is not larger than the component size of the restraint mother board 6, and the overlapping portion of the two boards is welded by side fillet welding. The joints 8 and the bolts 7 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap