Air spring, production equipment and production method thereof

An air spring, square technology, applied in the field of air spring and its production equipment and production, can solve the problems of lack of fire safety, insufficient means, and high cost, reduce the risk of air leakage, improve practicability and durability, increase Effect of Constraint Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 A kind of air spring

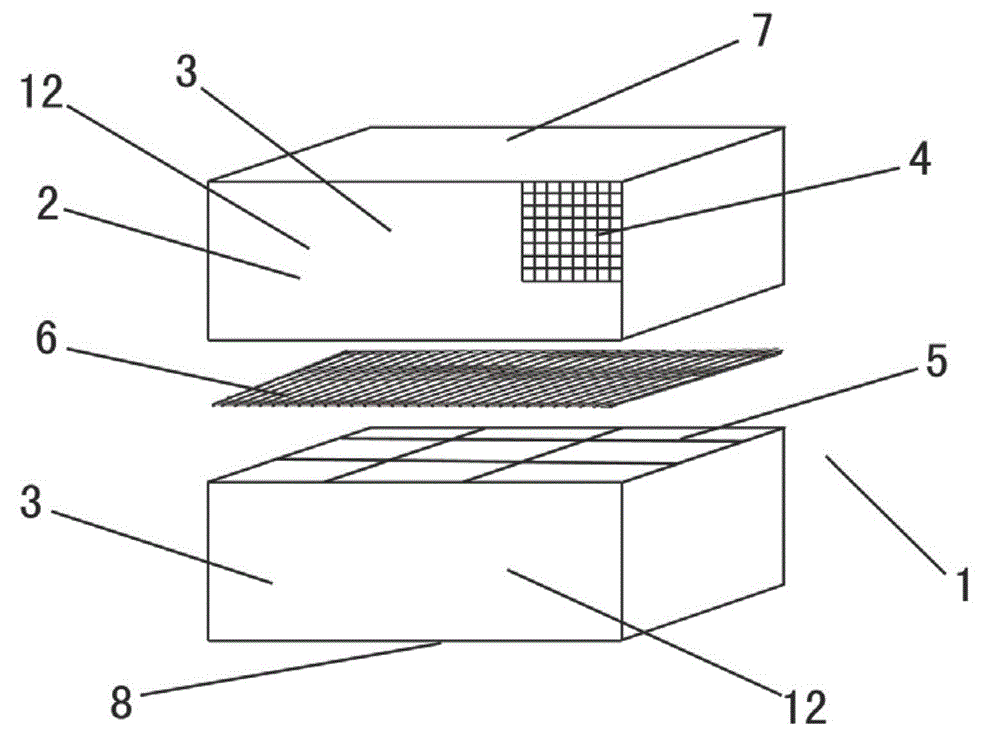

[0036] Referring to all the drawings, an air spring of the present invention includes an air spring body 1 for cushioning, a fiber bag 30 (not shown) for constraining the air spring body, and a supporting frame 31 (not shown) for supporting people shown) and sofa cover 32 (not shown).

[0037] A plurality of air spring bodies 1 are packaged into air cushions 33 (not shown) through fiber bags 30 and then arranged between the backrest 34 (not shown) of the support frame 31 and the jacket 32 and the seat plate 35 (not shown) of the support frame 31 and between seat surfaces 36 (not shown) to replace traditional metal springs or foam pads.

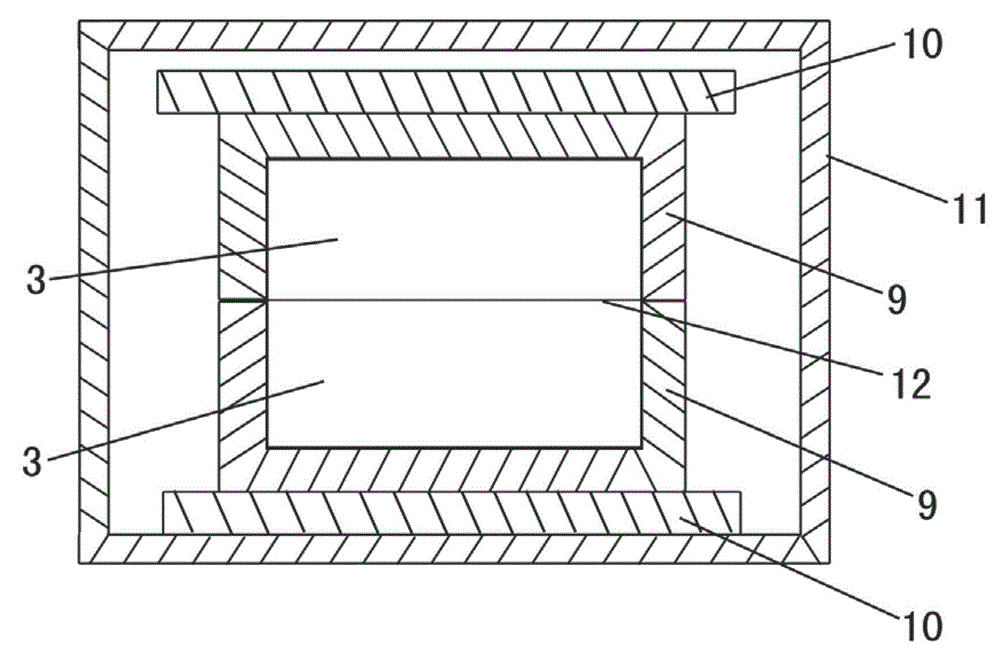

[0038] The air spring body 1 includes a primary tire 2 and a protective layer 13, and the primary tire 2 and the protective layer 13 are made of airtight plastic or rubber compounded with fiber. The primary tire 2 is composed of two standard square units 3, and the interior of the square unit 3 is...

Embodiment 2

[0041] Embodiment 2 The equipment for making the air spring body

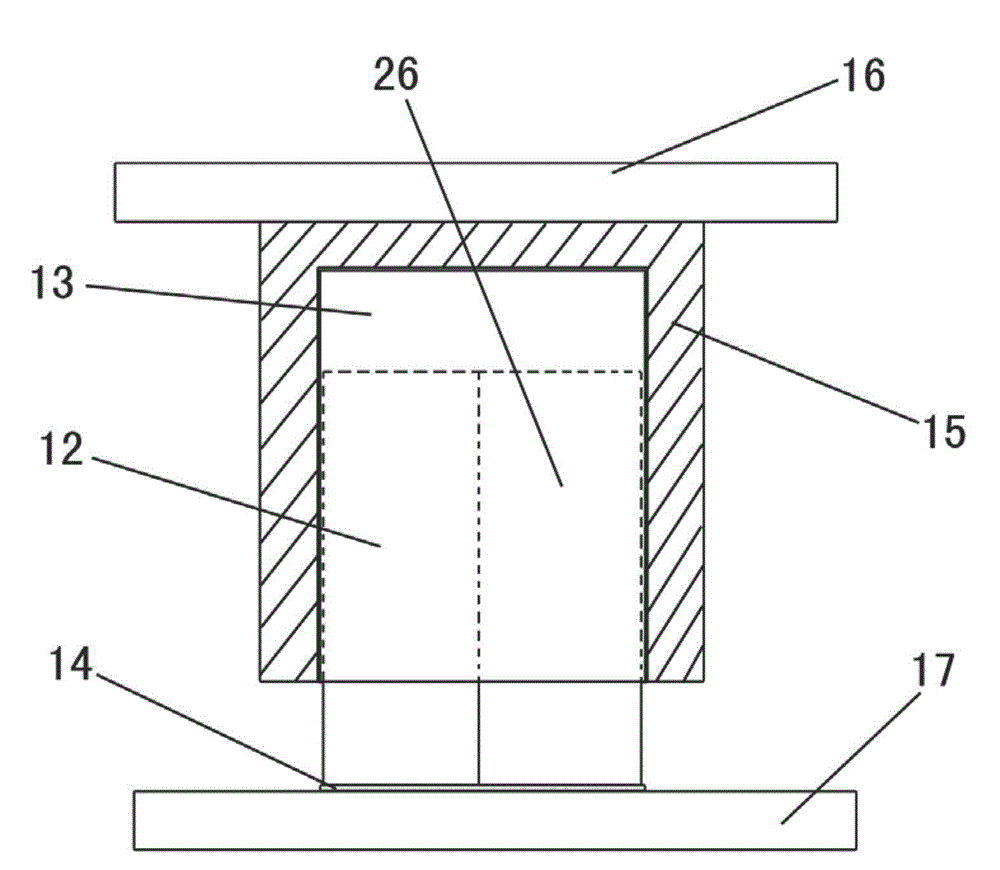

[0042] Referring to all the accompanying drawings, the equipment for making the air spring body 1 includes a mold 20 for making a square unit, and a production line for combining two square units 3 into a primary tire 2, and for wrapping a protective layer 13 on the primary tire 2 The sealing device 16.

[0043] The mold 20 for making the square unit 3 includes two parts: a shaping unit 25 and a molding unit 22 . The sizing unit 25 is used to fix the unit fiber bag 18 of the fiber layer 19 of the square unit 3 and is provided with a seam 29 for the tensile fiber 5 to enter inside it, and the forming unit 22 is used to accommodate the sizing unit 25 and is formed with The injection molding cavity is used to inject the prepared plastic and fiber layer 19 to form the square unit 3 after being combined with the shaping unit 25 . The fiber layer 19 includes unit fiber pockets 18 for strengthening the strength of t...

Embodiment 3

[0047] Embodiment 3 A method of making an air spring body, the steps of the method include:

[0048] 1) Making a square unit: In order to make the primary tire 2 have good cushioning performance, the layer 4 of the square unit 3 of the primary tire 2 is made of fiber and plastic composite, which strengthens the tire while ensuring the airtight seal. The strength of the layer 4, and the constraining portion 12 in the tire layer 4 is provided with tensile fibers 5 to limit its outward extensibility. The manufacture of the square unit 3 is firstly to weave the fiber layer 19, and the fiber layer 19 includes a unit fiber bag 18 for enhancing the strength of the tire layer 4 of the square unit 3 and tensile fibers for limiting the extensibility of the tire layer 5. The tensile fibers 5 are woven together with the fiber cloths of the unit fiber bags 18 of the respectively connected constraining surfaces and made to be perpendicular to the constraining surfaces where they are inflate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap