Lifting mechanism of vehicle-mounted electric lifting rod

A lifting mechanism and a lifting mechanism technology, which are applied to antennas, foldable antennas, and retractable units suitable for movable objects, etc., can solve problems such as the inability to meet the height requirements of vehicles and the unrestricted compression of the closed height of the electric lifting rod. , to reduce friction, improve maintainability, and facilitate maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

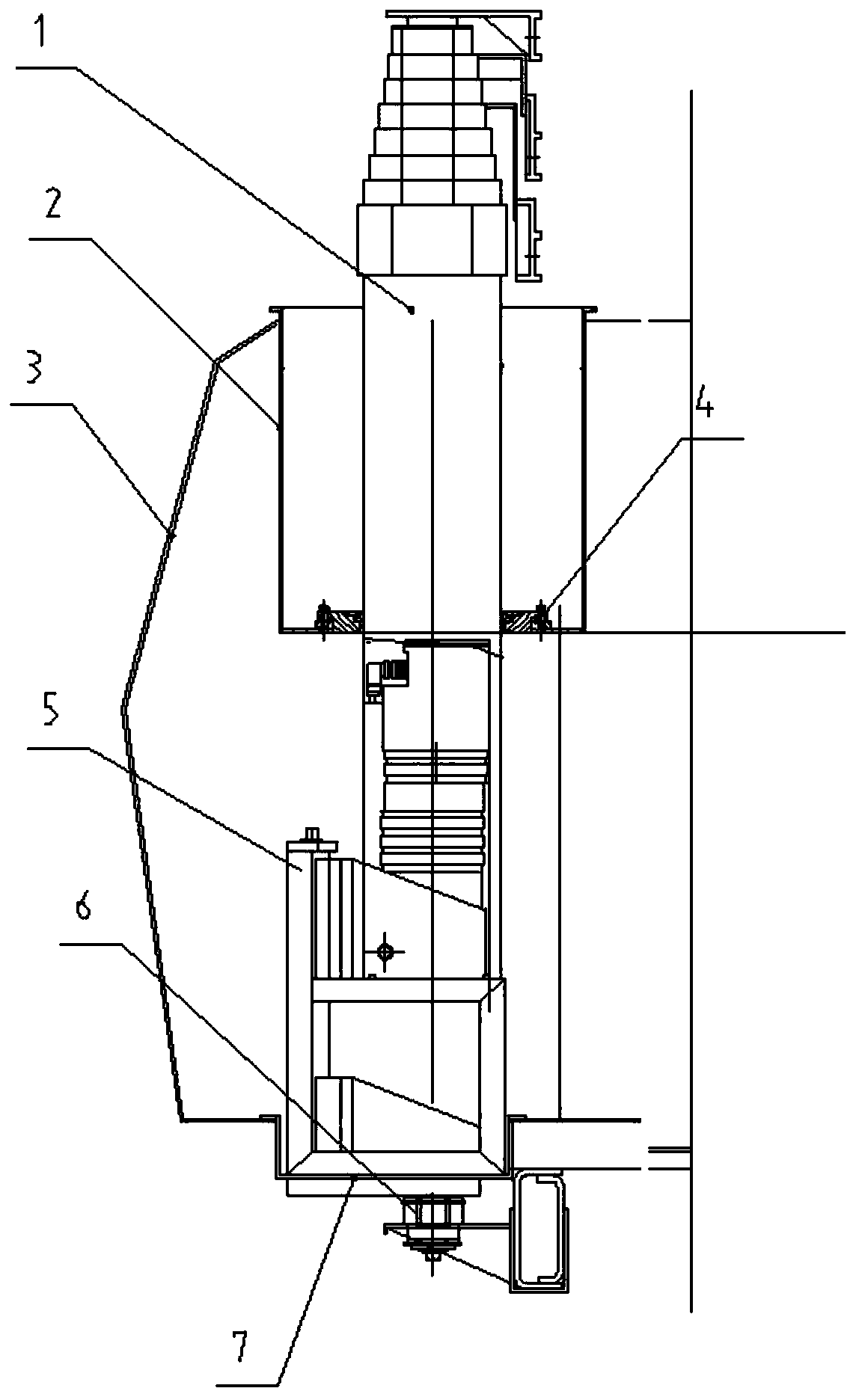

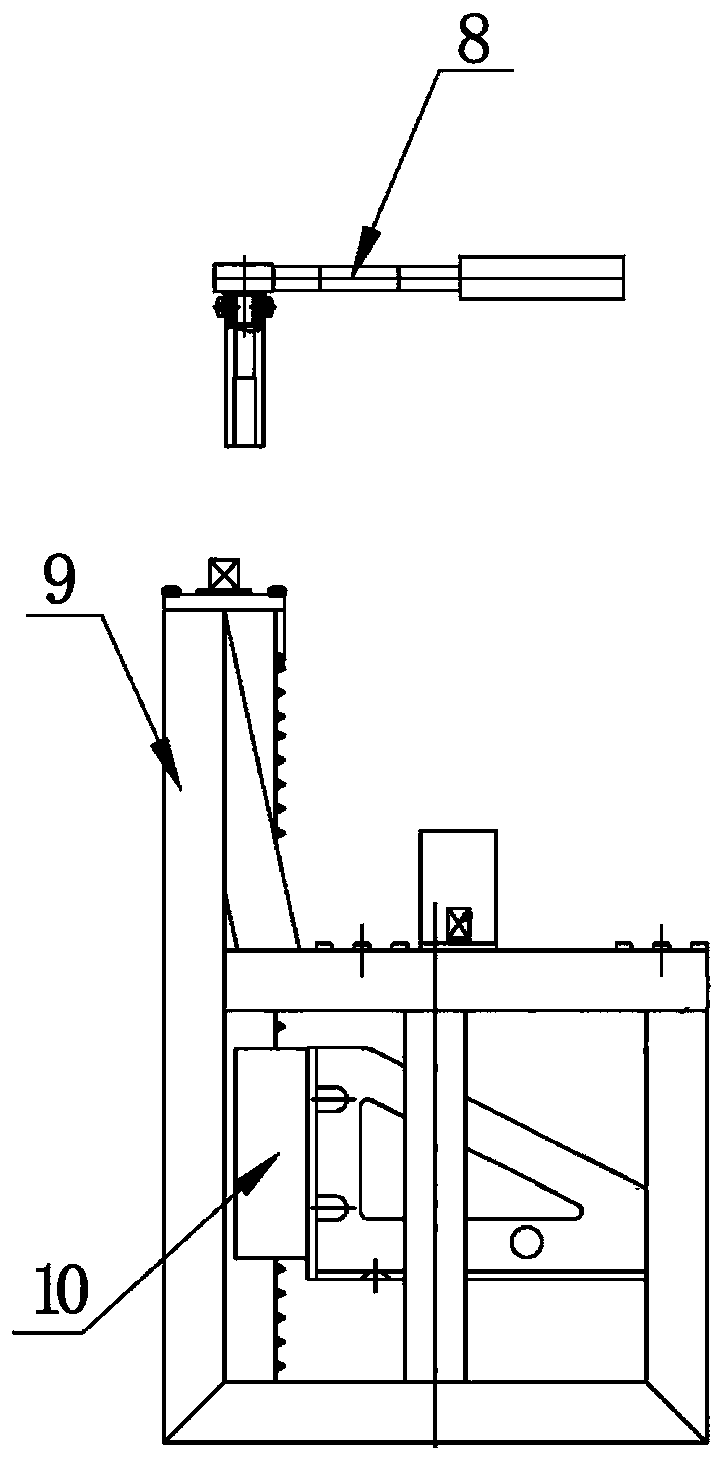

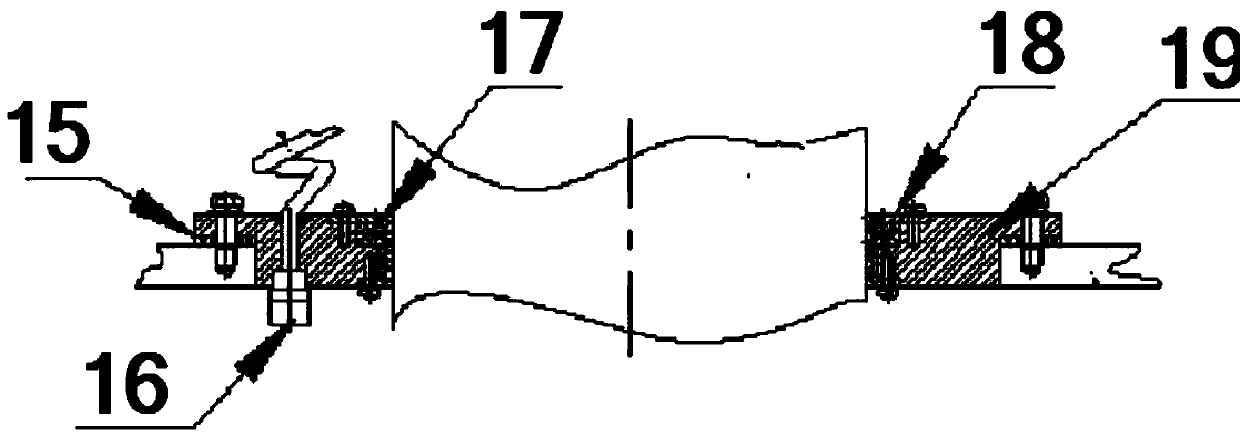

[0024] Reference Figure 1-Figure 4 To illustrate, the installation of the electric lifting rod lifting mechanism includes the basin 2, the sealing support ring 4, the lifting frame 5, the shock absorber 6 and other components. The seal support ring is composed of a seal ring 15, a rubber guide sleeve 17, a pressure plate 18, a connecting plate 19, etc.; the lifting frame includes a movable bottom frame 9, a bracket 10, a guide rail 11, a screw assembly 12, a slider 13, and the like.

[0025] A lifting mechanism for a vehicle-mounted electric lifting rod includes a lifting rod 1 for stretching to lift an antenna. The lifting rod is set up on a lifting mechanism for lifting the lifting rod, and the lifting mechanism drives the lifting rod to a vertical direction When raising and lowering, the lifting mechanism includes a base frame 9 as a fixed reference, a setting 12, a guide rail, and a movable bracket. The lead screw is installed on one side of the base frame, and a guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com