Linear guide rail sliding block

A linear guide rail slider and sliding seat technology, applied in the field of linear guide rails, can solve the problems of increased manufacturing costs, too many assembly steps, and low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

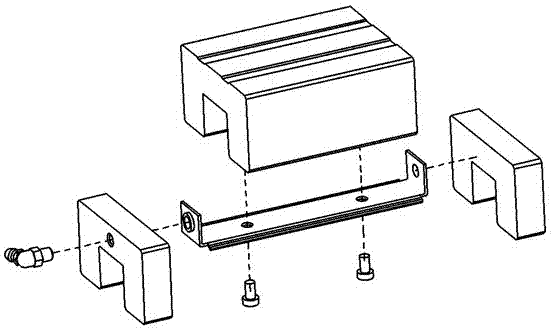

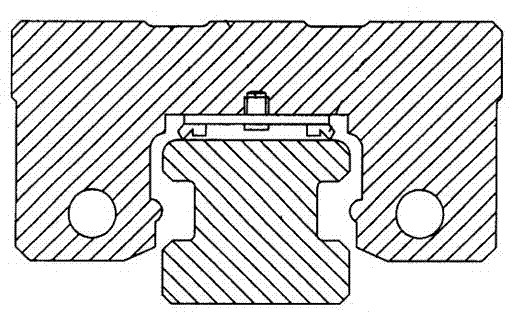

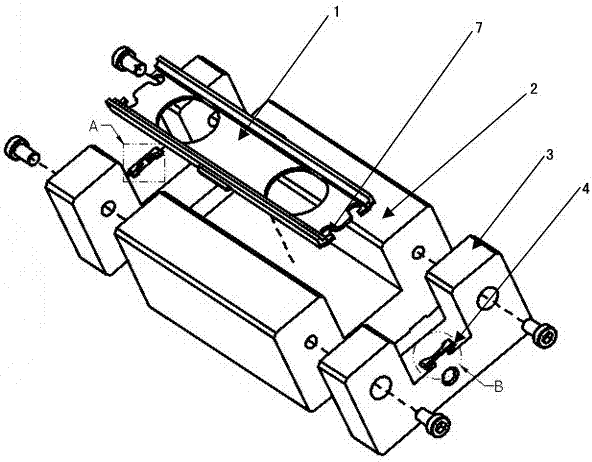

[0025] The linear guide rail slider of the present invention includes an end cover 3, a sliding seat 2, and an internal sealing sheet 1. The end cover 3 is arranged at both ends of the sliding seat 2, and the internal sealing sheet 1 is arranged between the two end covers 3 on the sliding seat 2. On the inner side of the end cover 3, a card 4 with an interference fit between the opening shape and the end of the inner sealing sheet 1 and parallel to the sliding seat 2 is provided on the end cover 3. The card 4 is fixed on the end cover 3 through a support body 5, and the two end cover cards The distance between the 4 openings is slightly less than the length of the internal sealing sheet 1. A slope is provided on the edge of the opening of the card 4 . The distance between the card 4 and the inner side of the sliding seat 2 is matched with the thickness of the inner sealing sheet 1, and the edges of the inner sealing sheet 1 on both sides of the support body 5 are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com