Universal supporting device for solid-propellant rocket engines

A support device, solid rocket technology, applied in the direction of engine base, supporting machine, mechanical equipment, etc., can solve problems such as hidden safety hazards and insufficient support, and achieve the effect of preventing deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

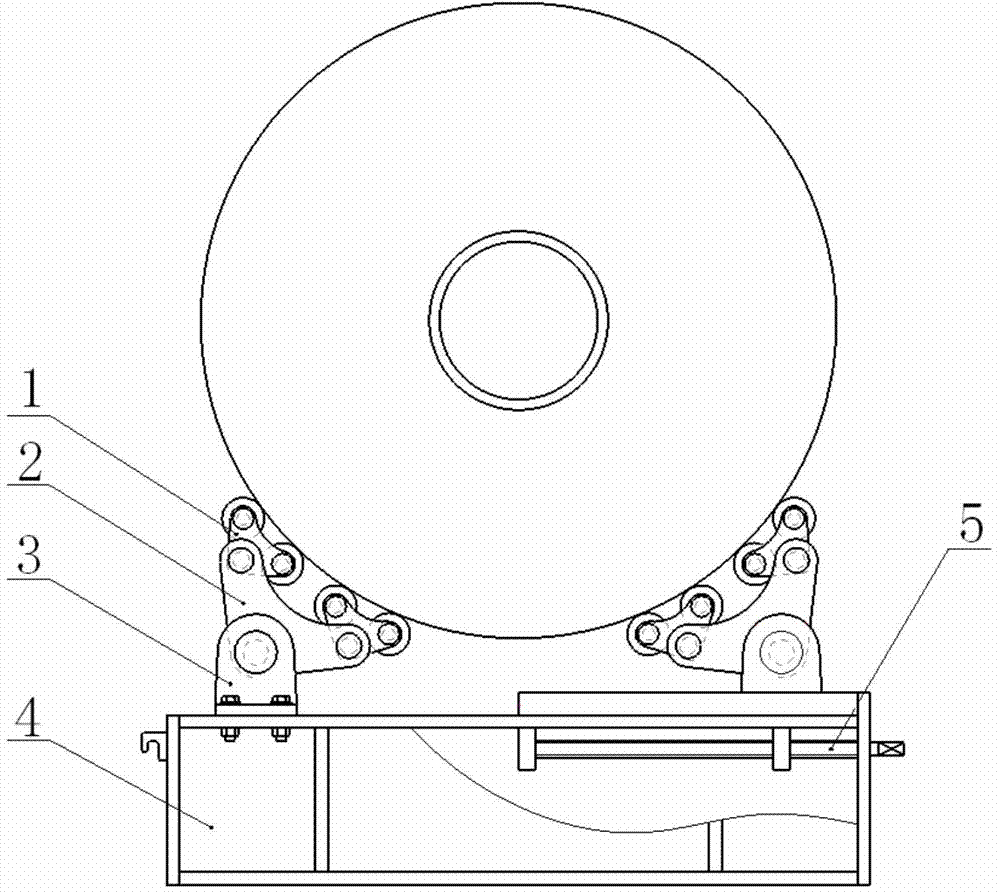

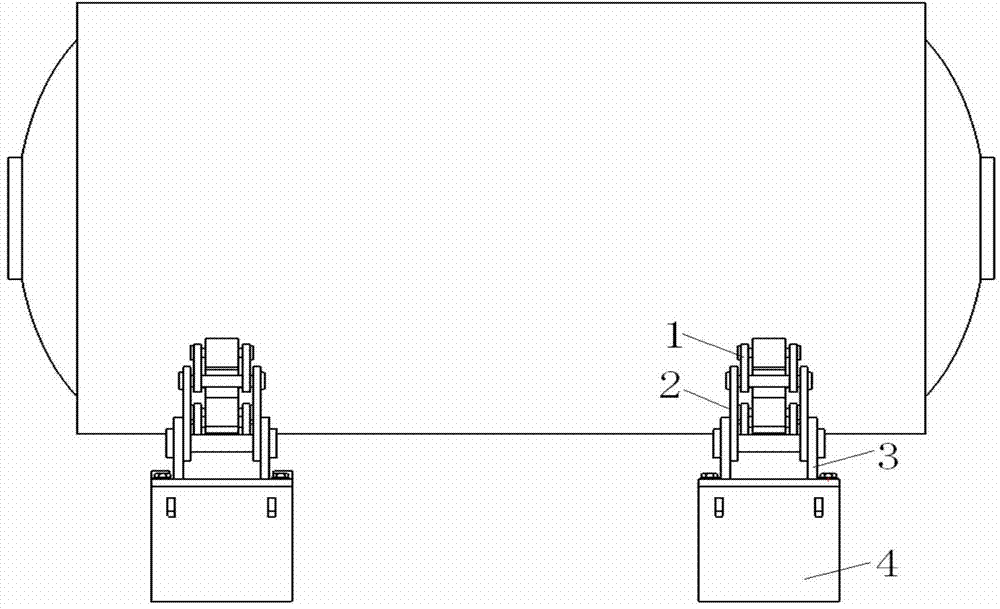

[0015] This embodiment is a general support device for solid rocket motors, including 4 sets of small hinges 1, 4 large hinges 2, 4 support bases 3, brackets 4 and lead screws 5. Wherein, one end of the upper surface of the bracket 4 is equipped with a lead screw 5 through a lead screw seat. Two of the four support seats 3 are installed on the lead screw 5 through a lead screw connection block, and the other of the four support seats 3 Two support seats are fixedly installed on the upper surface of one end of the support 4 without a lead screw. During use, the positions of the two support seats 3 at one end of the support are adjusted by the lead screw to support products of different diameters.

[0016] Four large hinges 2 are installed on four support bases 3 respectively. The four groups of small hinges 1 are installed on the four large hinges 2 respectively. The four groups of small hinges 1 constitute the supporting surface of the product. The positions of the four supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com