Combination gauge for abnormal bearing inner ring pore detection and detection method thereof

A technology of bearing inner ring and combined gauge, applied in the direction of measuring device, mechanical device, mechanical measuring device, etc., can solve the problems of high cleanliness requirements of bearing inner ring, high pressure stability requirements, affecting measurement accuracy, etc. Achieve the effect of improving inspection efficiency, easy observation, and high inspection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

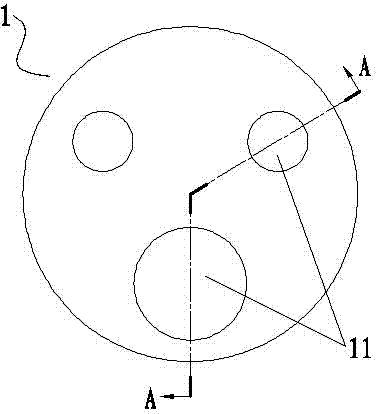

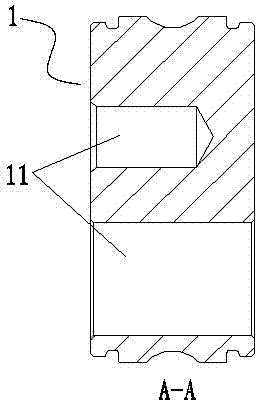

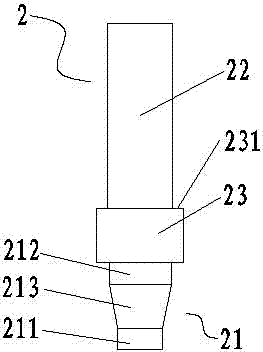

[0033] See attached picture. The combination gauge for inspecting small holes in the inner ring of special-shaped bearings provided by the embodiment of the present invention includes a plug gauge 2 for detecting whether the size of the small hole 11 on the inner ring 1 of the bearing meets the tolerance requirements, and is used to detect the inner ring of the bearing in cooperation with the plug gauge Whether the position of the small hole meets the tolerance requirements of the ring gauge 3, and the pressure plate 4 used in conjunction with the ring gauge and plug gauge.

[0034] One end of the plug gauge is a detection end 21 for detecting whether the size of the small hole in the inner ring of the bearing meets the tolerance requirements, and the other end of the plug gauge is a positioning end 22 used in conjunction with the ring gauge 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com