Subsoiler stress testing device

A technology of testing device and deep loosening shovel, applied in the direction of measuring device, measuring force, instrument, etc., can solve the problems of small depth adjustment range, cumbersome sticking of strain gauges, and high technical requirements for operation, and achieves simple and convenient height adjustment and testing cost. Low cost, good overall flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

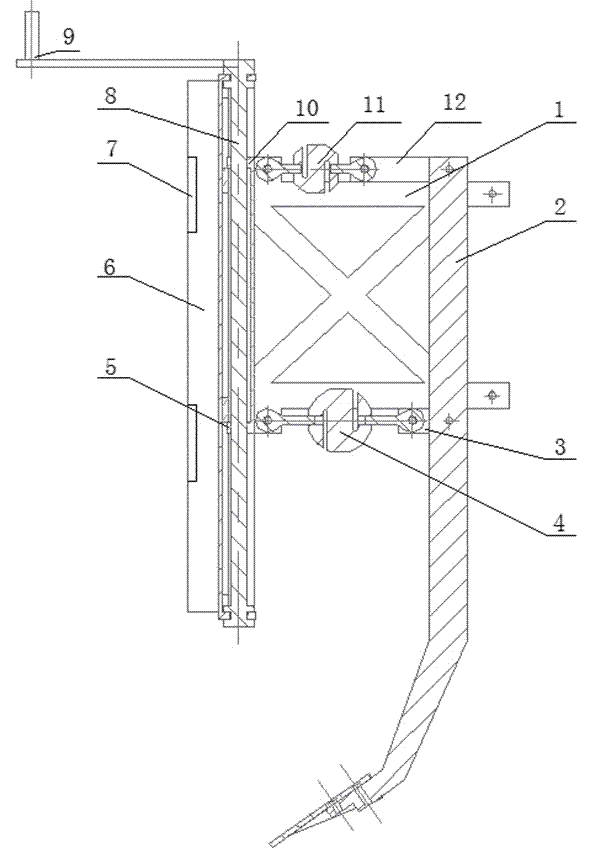

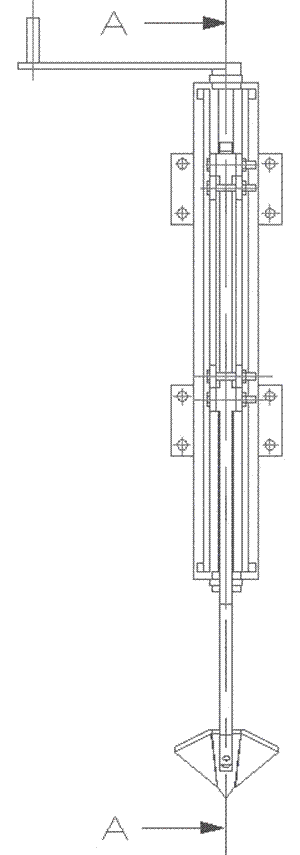

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A force test device for subsoiling shovels. A lead screw 8 with a handle 9 is installed on the slideway body welded 6 axially, radially and rotatably in the circumferential direction. On the upper and lower sides of the lead screw 8 The upper nut 10 and the lower nut 5 are respectively movable up and down on the upper part, and the frame welding 1 is fitted on the slideway body welding 6 so as to be movable up and down, and the upper nut 10 and the lower nut 5 are respectively welded to the frame 1 The upper side and the lower side are affixed; on the upper end side and the middle side of the subsoiling shovel assembly 2, the two upper connecting plates 12 and the two lower connecting plates 3 are hinged and installed respectively. The two ends of the upper pull-pressure sensor 11 are respectively welded to the frame 1, the hinge connection of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com