An airtightness detection device for a cylindrical cell

An air-tightness detection and cell technology, which is applied in the use of liquid/vacuum for liquid-tightness measurement, by detecting the appearance of fluid at the leak point, etc. Influence of internal physical and chemical properties, etc., to reduce detection efficiency and cost, optimize detection links, and prevent contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

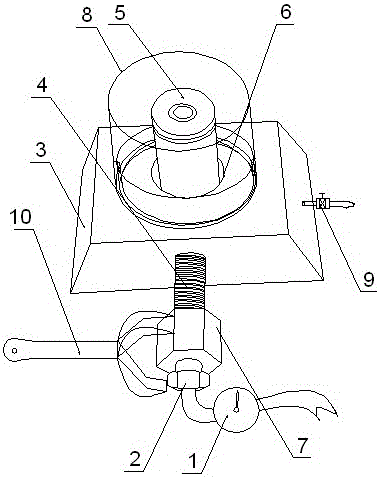

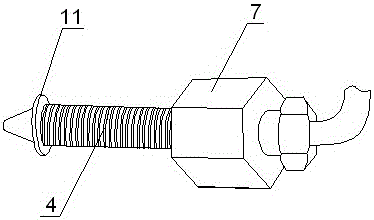

[0020] Such as figure 1 As shown, an airtightness detection device for a cylindrical cell includes a barometer 1, a high-pressure air pipe joint 2, a base 3 and an inflatable joint. The inflatable joint includes a tapered hollow threaded rod 4 at the front and an inlet For the mechanism, the base 3 is provided with a mounting hole 6 with a diameter slightly larger than the diameter of the battery core 5 to be tested, and the side wall of the mounting hole 6 is provided with a threaded hole through a tapered hollow threaded rod 4, and the inflatable joint 4 The tail end is movably connected to the high-pressure air pipe joint 2, the air pressure gauge 1 is connected in series to the high-pressure air pipe joint 2, and a liquid storage device is arranged on the upper part of the base 3, and the liquid storage device includes a A liquid storage bin 8 and a liquid discharge valve 9 on one side of the installation hole 6 are provided.

[0021] The liquid storage bin 8 is screwed t...

Embodiment 2

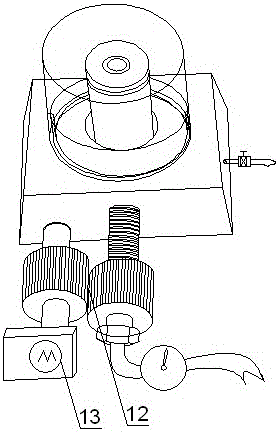

[0027] Such as image 3 As shown, an airtightness detection device for a cylindrical battery cell differs from the first embodiment in that the feeding mechanism includes a gear pair 12 and a driving motor 13 .

[0028] The method of using the airtightness detection device for the cylindrical battery cell in the present invention is the same as that in the first embodiment.

Embodiment 3

[0030] Such as figure 1 , Figure 4 As shown, an airtightness detection device for a cylindrical battery cell differs from Embodiment 1 in that a transparent arc-shaped cover 14 is provided at the top of the liquid storage bin 8, and a syringe is provided at the top of the arc-shaped cover 14. The liquid port 15, the arc-shaped sealing cover 14 is threadedly connected with the liquid storage chamber 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com