Drum-type washing machine

A drum-type washing machine and washing water technology, which is applied to other washing machines, washing machines with containers, control devices of washing machines, etc., can solve problems such as inability to obtain sufficient cleaning and rinsing effects, and inability to spray washing water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

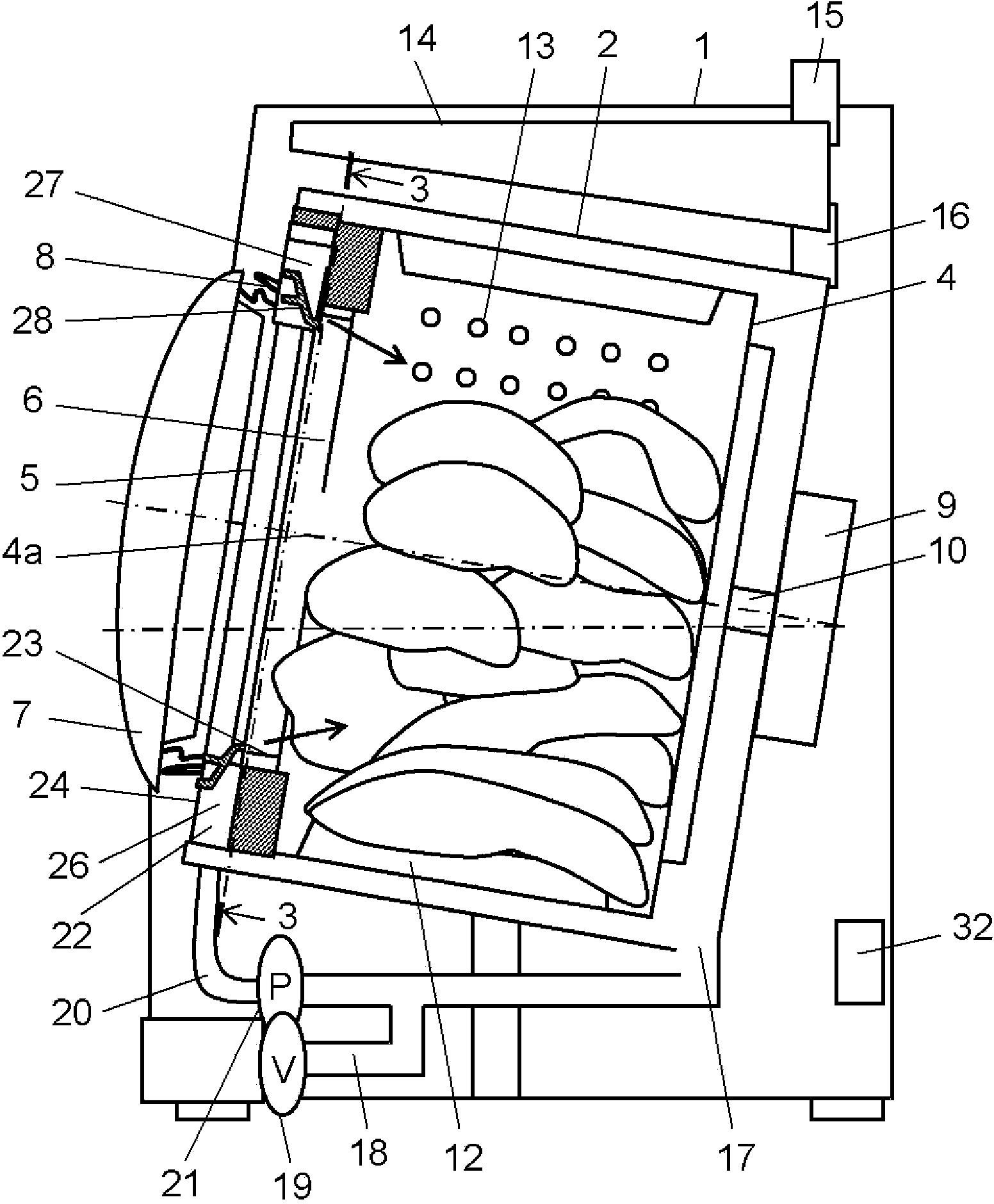

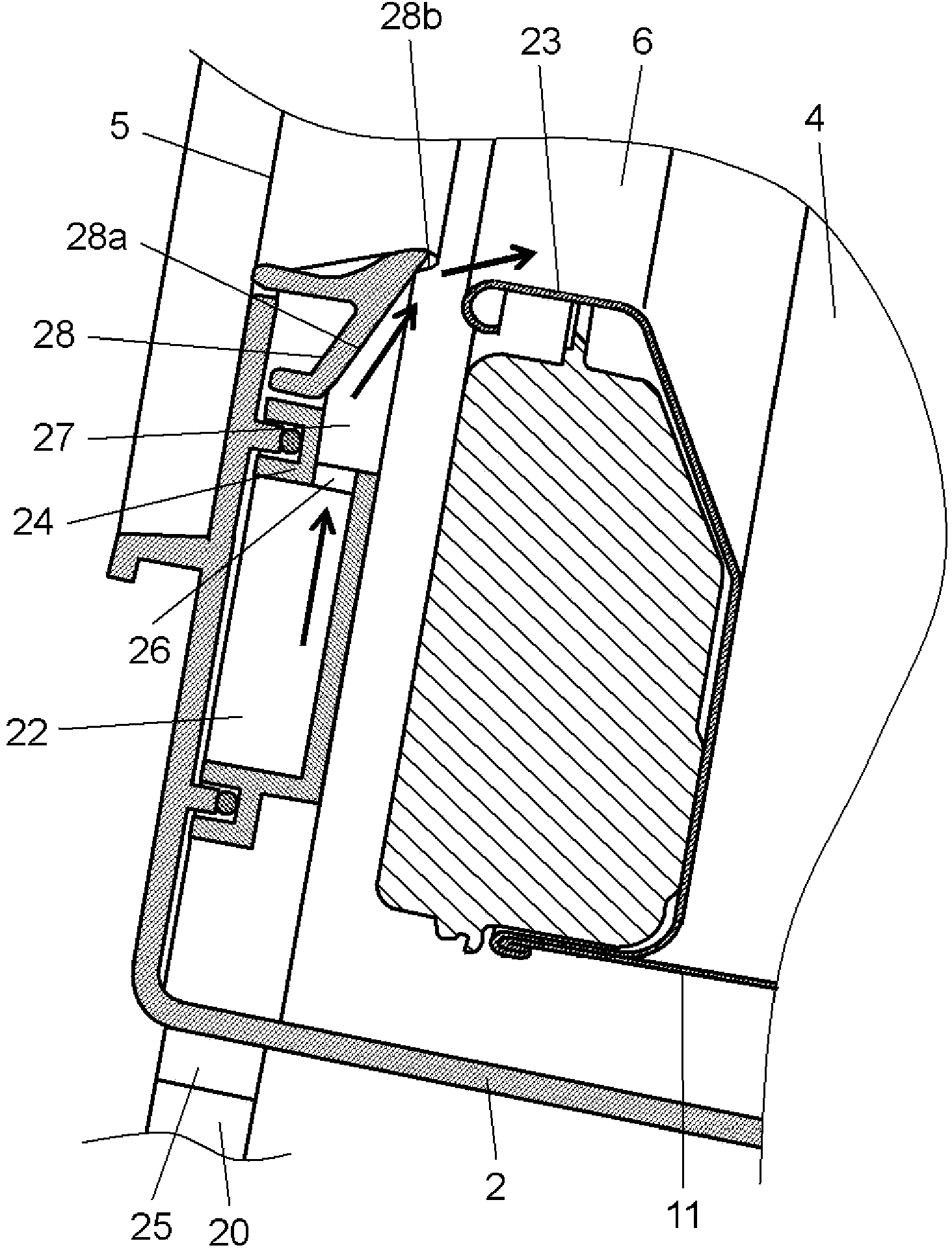

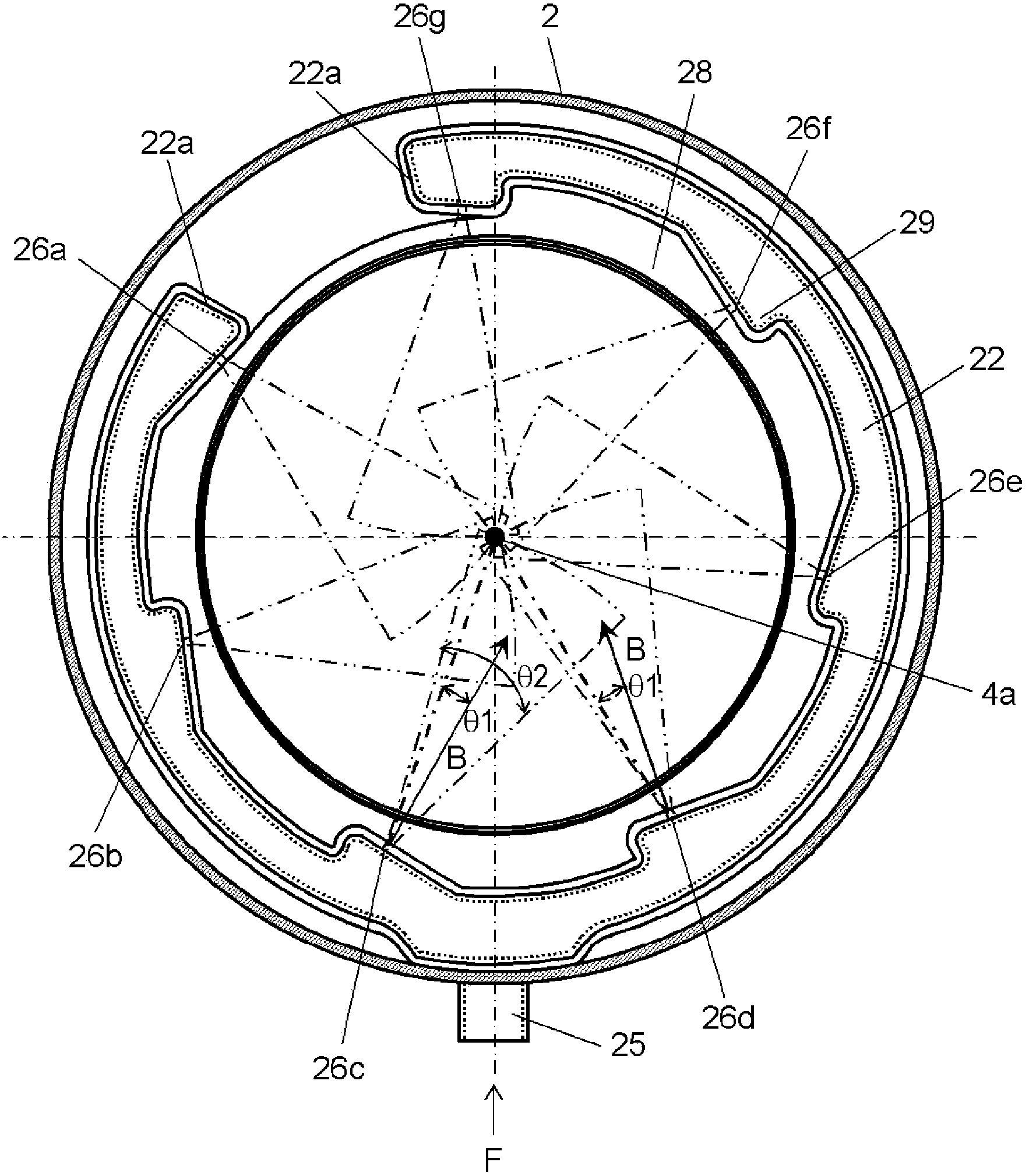

[0023] Next, Embodiment 1 of the present invention will be described with reference to the drawings. figure 1 A cross-sectional view showing a schematic configuration of the front-loading-type washing machine according to Embodiment 1 of the present invention. figure 2 It is a main part sectional view of the front-loading-type washing machine in Embodiment 1 of this invention. image 3 of the front-loading washing machine according to Embodiment 1 of the present invention figure 1 3-3 way view. Figure 4 It is a sectional view of the nozzle of the front-loading-type washing machine in Embodiment 1 of this invention.

[0024] exist Figure 1 ~ Figure 4 Among them, a water tank 2 formed in a bottomed cylindrical shape is elastically supported in a casing 1 . A bottomed cylindrical rotary tank 4 is rotatably disposed in the water tank 2 . The rotation axis 10 of the rotation tank 4 substantially coincides with the cylindrical centerline of the rotation tank 4 , and the rota...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap