Brake device mounted on flight experience device

A brake device and brake pad technology, which is applied in the field of brake devices, can solve the problems of affecting the safety effect, hidden safety hazards, and long time-consuming locking, and achieve the effects of reasonable structural design, extended service life, and good braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

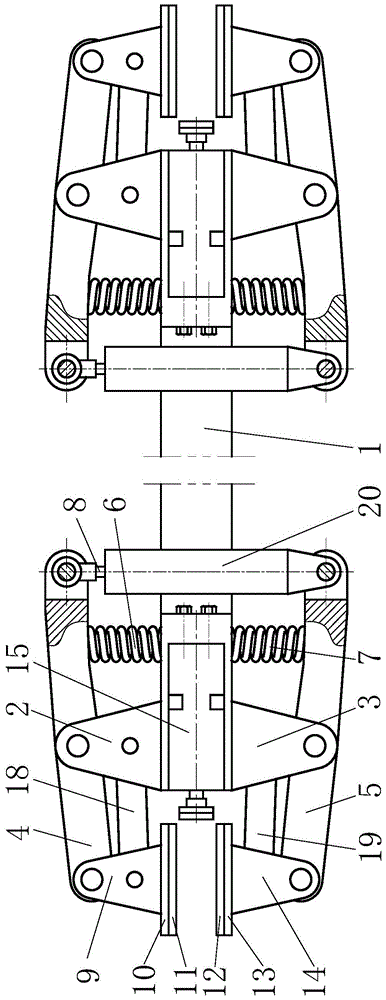

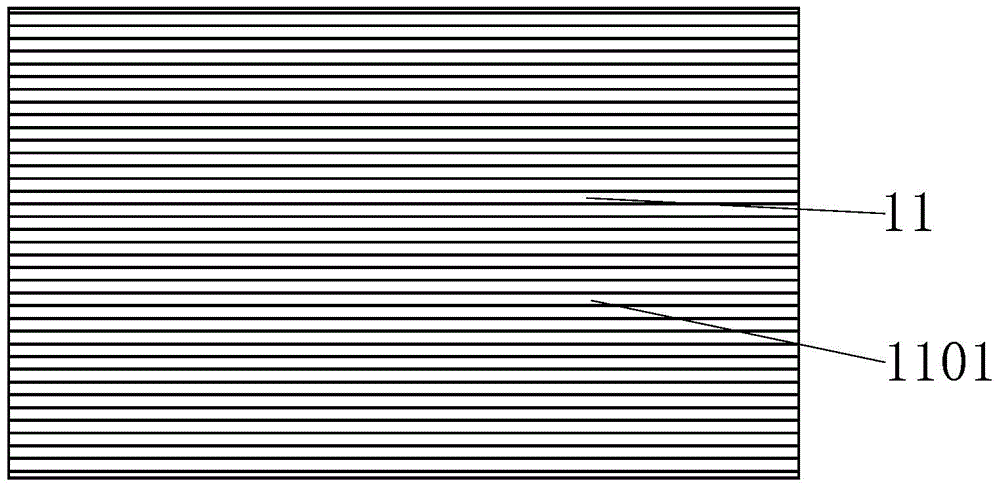

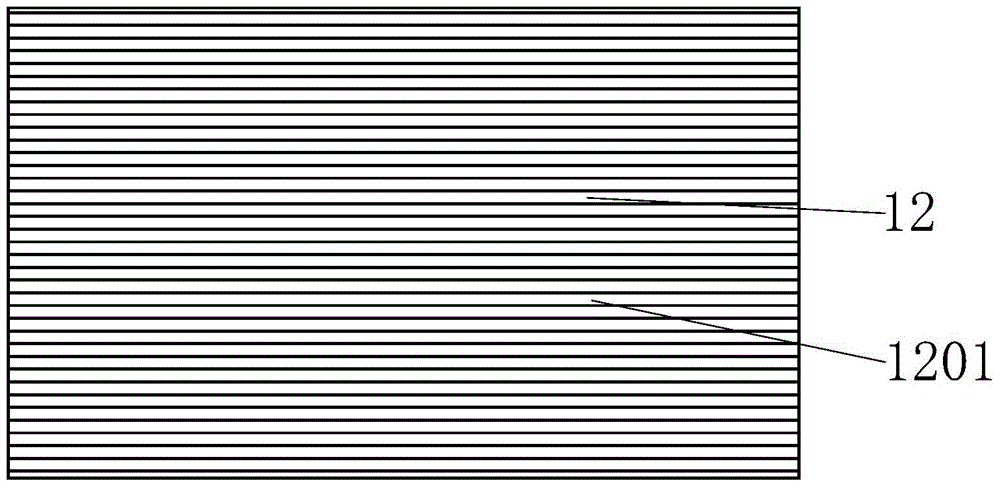

[0021] like Figure 1 to Figure 5 As shown, a brake device installed on a flight experience device includes a support platform 1, and combined brakes are symmetrically installed on the left and right ends of the support platform 1, and the combined brake includes an upper main support 2, The lower main support 3 and the lateral brake, the upper main support 2 and the lower main support 3 are symmetrically installed on the upper and lower sides of the support platform 1, and the upper main support 2 is connected with an upper lever in a hinged manner Beam 4, the left end of the upper lever beam 4 is connected with the upper brake pushing block 9 through a hinged mode, the middle part of the right side of the upper lever beam 4 is connected with the support platform 1 through the upper te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com