A Flame Straightening Process for Shearing Machine Blades

A flame straightening and shearing machine technology, which is applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of difficulty in determining the position of the fulcrum pad, cracks in the blade of the shearing machine, repeated orthosis, etc., and achieves good correction effect. , the effect of eliminating flexural deformation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

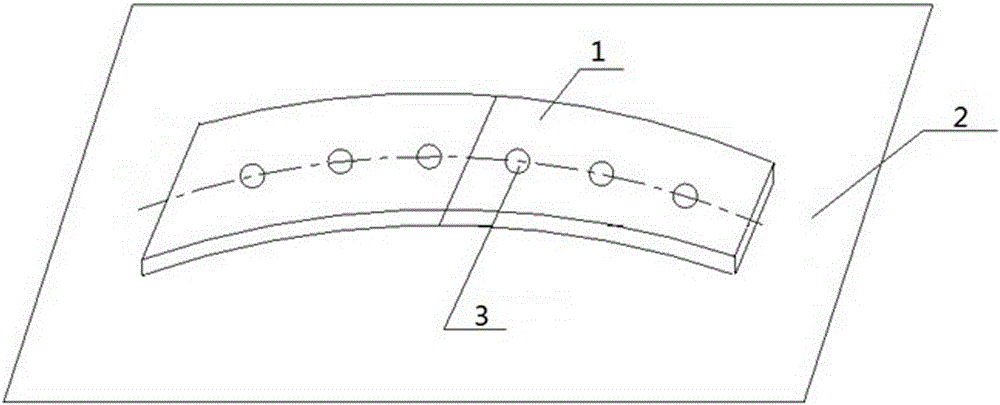

[0013] like figure 1 The blade flame straightening process of the plate shearing machine is shown. Firstly, the blade 1 with the bending deflection 0<f≤3mm is placed upward on the working platform 2, and the high point of the convex surface of the blade 1 is taken as the reference point, and the two sides along the length direction are uniformly selected. Heating dot 3, the heating dot 3 is located on the center line of the blade length direction, the diameter of the heating dot 3 is 10-30mm, and the distance between adjacent heating dots 3 is 60-80mm; then the heating dot 3 is heated , the temperature of the heating area is 150~280°C; after the heating is completed, let the heating area enter an air-cooled state, so that the blade 1 is naturally cooled to room temperature, and the deflection of the blade 1 is eliminated, and the correction of the blade 1 is completed.

Embodiment 2

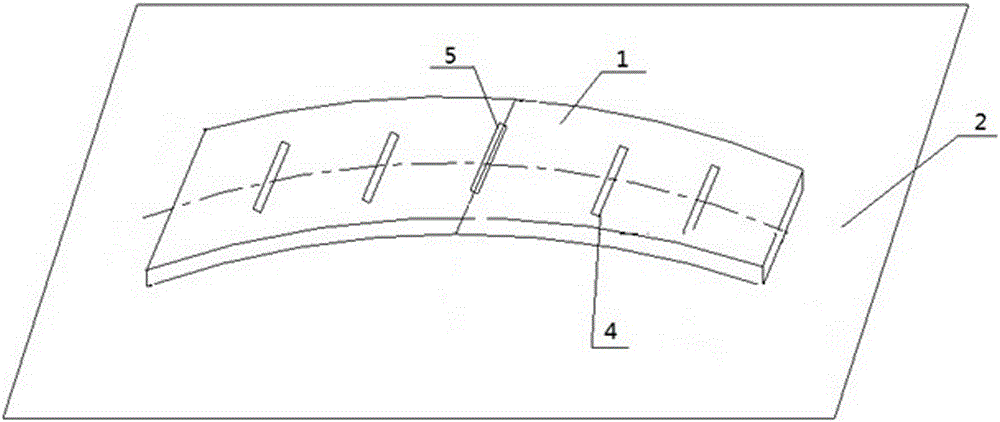

[0015] like figure 2 Shown is a shearing machine blade flame straightening process, first the bending deflection 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com