Flexible thin plate positioning fixture based on T-type groove

A technology for positioning fixtures and thin plates, which is applied to manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of difficulty in establishing an assembly deviation analysis model, and achieve the effect of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

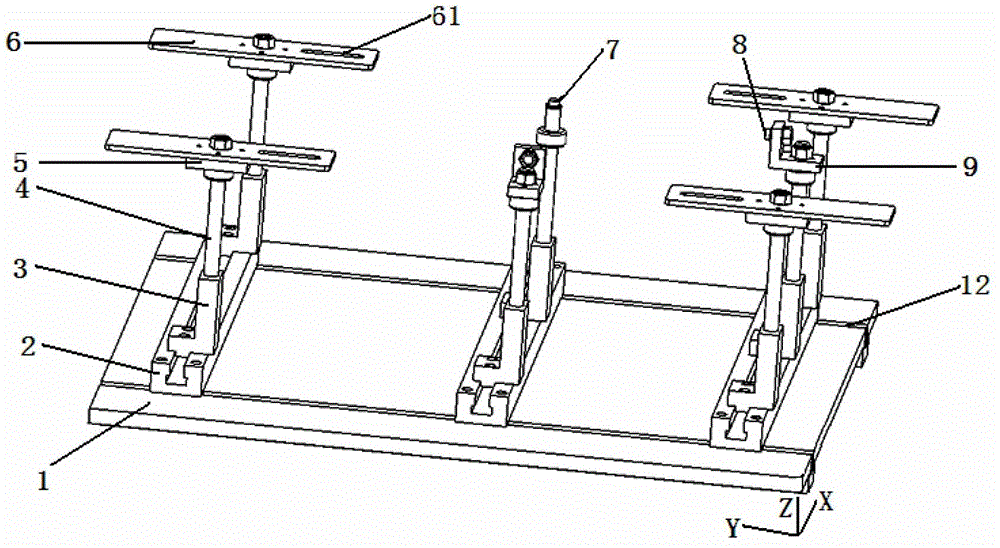

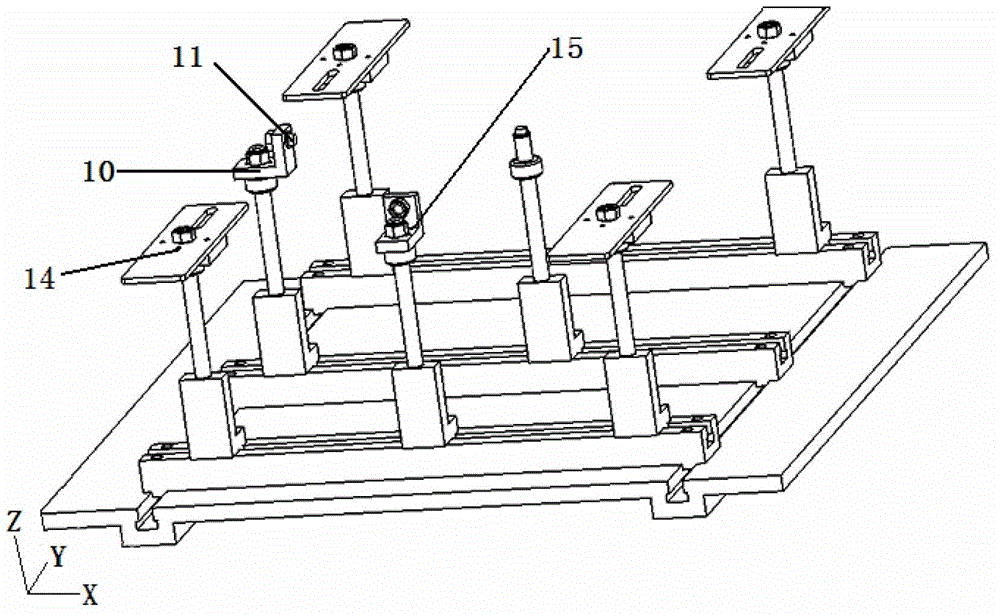

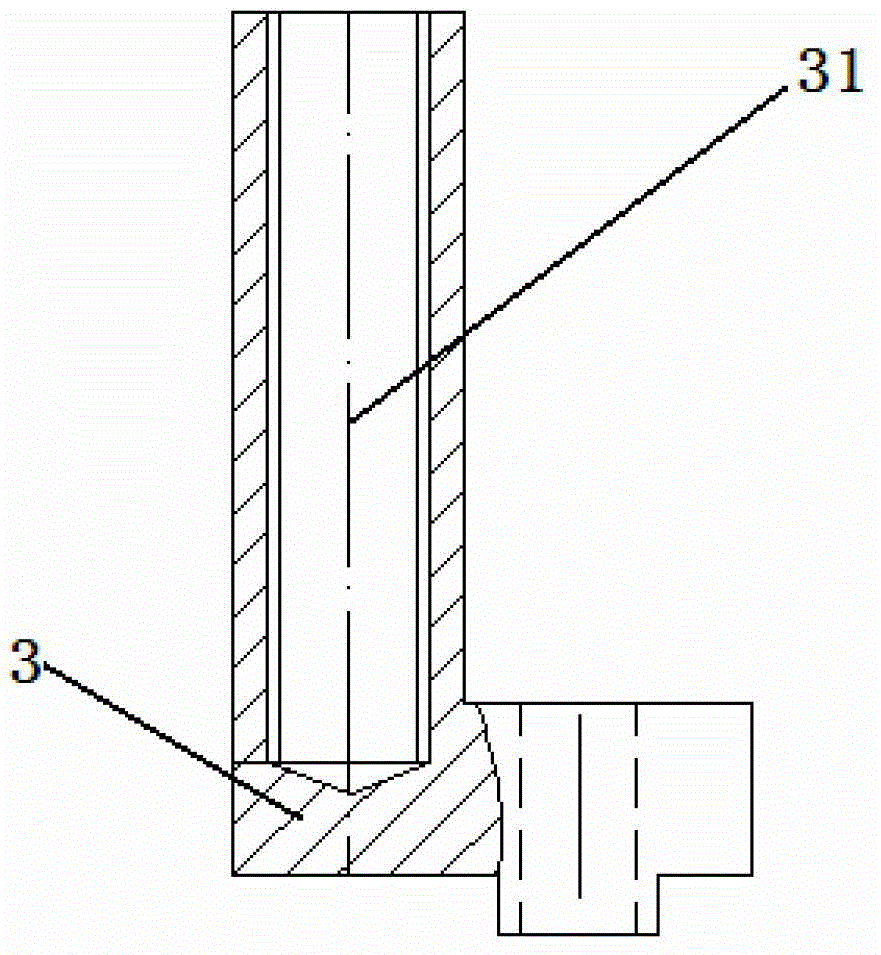

[0031] A flexible thin plate positioning fixture based on T-slot, the structure is as follows figure 1 and figure 2 As shown, the positioning fixture includes a fixture base plate 1, a T-slot slider 2, a support slider 3, a stud bolt 4, and positioning pins (including X-directional positioning pins 11, Y-directional positioning pins 8 or Z-directional positioning pins 7) , a positioning plate 5 and a chuck bracket 6, multiple T-slot sliders 2 are provided, which are slidably connected to the fixture bottom plate 1, and each T-slot slider 2 is slidably connected to 2 to 3 support sliders 3, double The lower end of the head bolt 4 is connected to the support slider 3, and the upper end of the stud bolt 4 is connected to the positioning pin (X-direction positioning pin 11, Y-direction positioning pin 8 or Z-direction positioning pin 7) or the chuck bracket through the positioning plate 5 6. Adjust the height of the positioning pin (X-direction positioning pin 11, Y-direction po...

Embodiment 2

[0043] Such as figure 1 with figure 2 As shown, the positioning fixture based on the T-slot flexible thin plate includes a fixture base plate 1, a T-slot slider 2, a support slider 3, a stud bolt 4, a positioning plate 5, a chuck bracket 6, and a Z-direction positioning pin 7. Y-direction positioning pin 8, Y-direction positioning pin bracket 9, X-direction positioning pin bracket 10, X-direction positioning pin 11.

[0044] There are three T-shaped groove sliders 2, which are evenly distributed on the fixture base plate 1, and each T-shaped groove slider 2 is fixed on the fixture base plate 1 by bolts and nuts so that it cannot move. Set seven support sliders 3 to be installed on the T-slot slider 2, and adjust their positions according to requirements, and then use T-slot bolts and nuts to fix the support slider 3. Install seven stud bolts 4 on the support slider 3, and adjust the thread fit position according to the height requirement. Install the positioning plate 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com