Robotic arm for test sampling

The technology of a robotic arm and a robotic arm is applied in the field of robotic arms for testing and sampling, which can solve the problems of high risk, high labor intensity, and easy occurrence of burns, and achieve the effects of reducing labor intensity, avoiding friction damage, and stable and reliable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

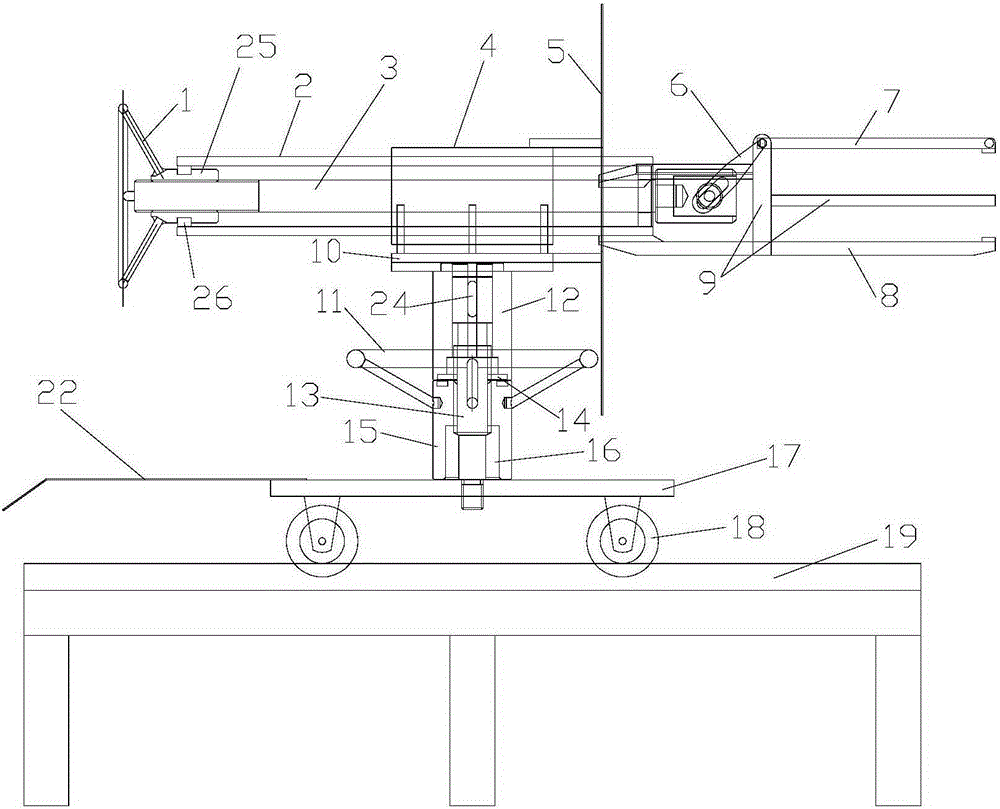

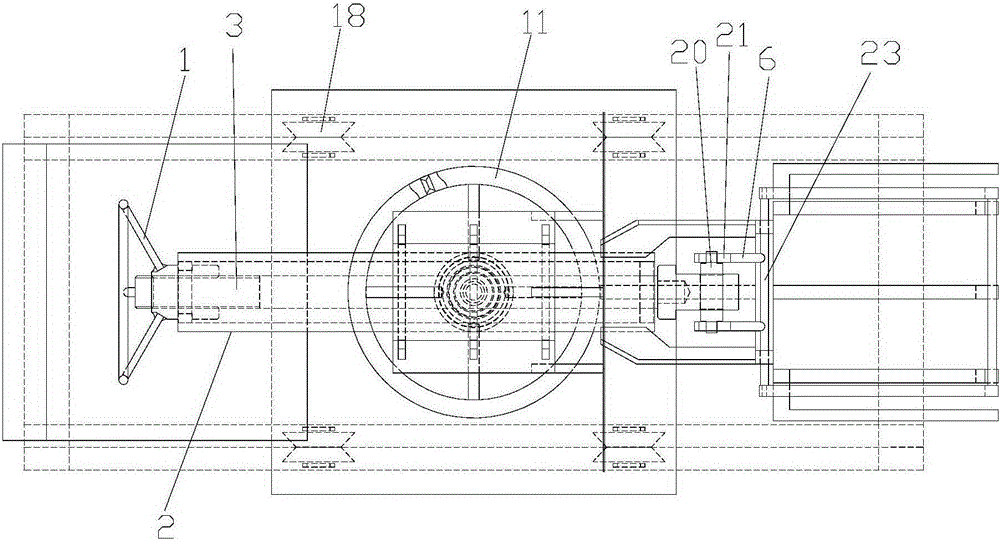

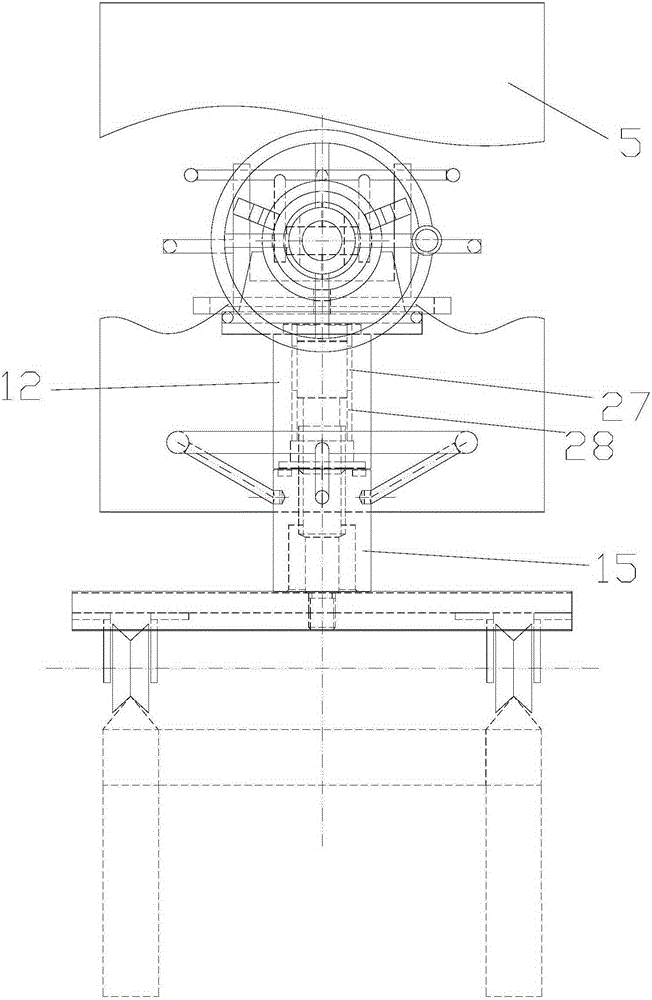

[0029] like Figure 1 to Figure 7 As shown, the test sampling mechanical arm of the present invention comprises a walking mechanism, a lifting mechanism is arranged on the walking mechanism, the lifting mechanism is connected with the supporting platform, a mechanical arm 2 is arranged above the supporting platform, and a mechanical arm 2 is covered with a supporting platform 10 Connected supporting sleeve 4, the axial direction of supporting sleeve 4 is perpendicular to the lifting direction of the lifting mechanism, the mechanical arm 2 and the supporting sleeve 4 rotate and cooperate, one end of the mechanical arm 2 is provided with a clamping mechanism, and the other end of the mechanical arm is provided with There is a clamping mechanism operating handle 1, a first heat insulation baffle 5 connected to the support table 10 is arranged betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com