Magnetic attracting type mechanical arm with adjustable positions

A magnetic adsorption and manipulator technology, applied in the field of manipulators, can solve problems such as the inability to adjust the position of the gripping end of the manipulator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

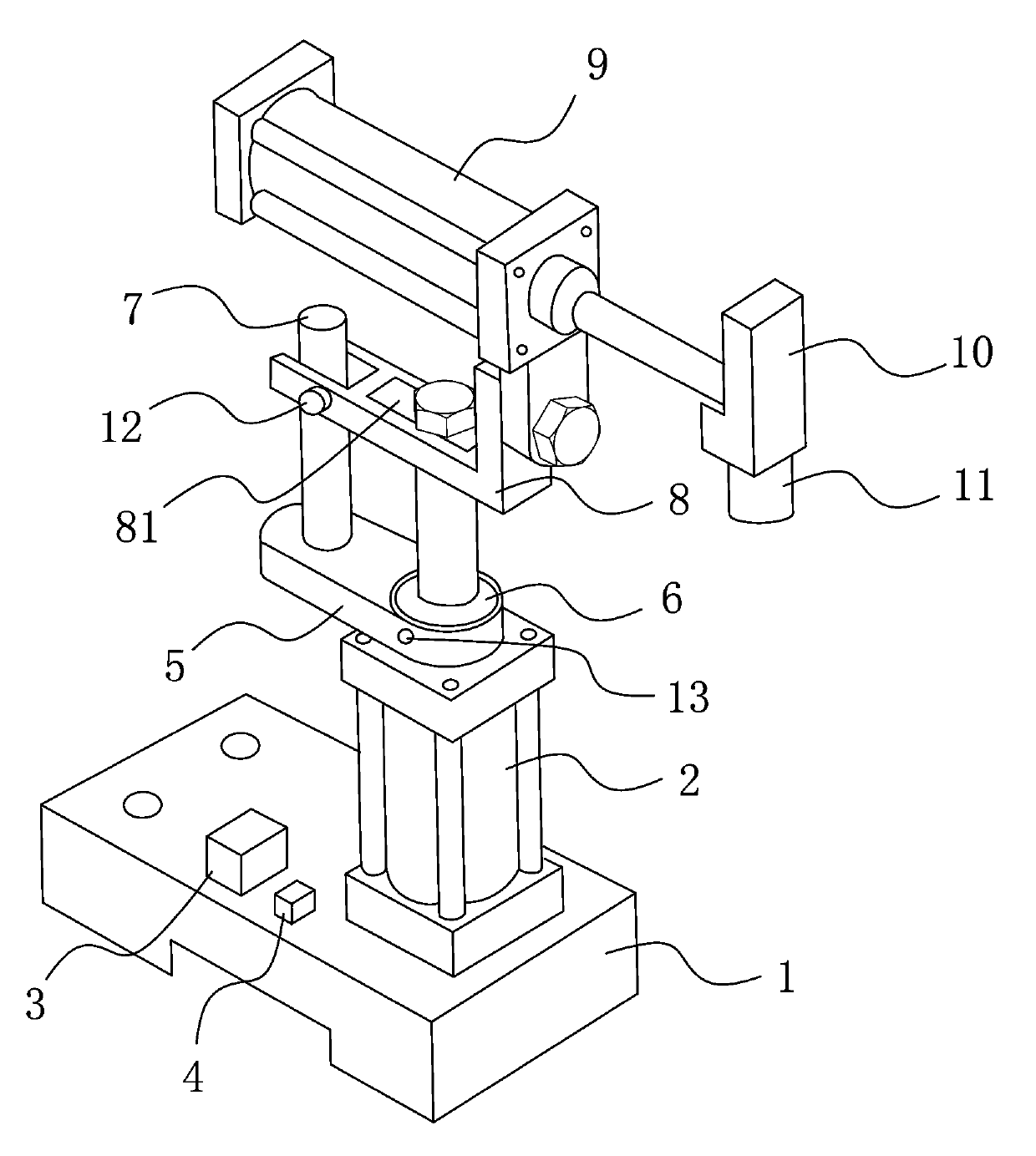

[0011] Such as figure 1 As shown, a position-adjustable magnetic adsorption manipulator includes a base 1 with mounting holes, a power structure and a grabbing structure. The power structure includes a vertical cylinder 2 and a horizontal cylinder 9, and the ends of the vertical cylinder 2 are connected to On the base 1; the grasping structure includes a mounting plate 10, an electromagnet 11 connected to the bottom of the mounting plate 10, a storage battery 3 and an electronic timer 4, the mounting plate 10 is connected to the piston rod end of the horizontal cylinder 9, and the storage battery 3 is arranged on On the base 1, the coil in the electromagnet 11 is electrically connected with the electronic timer 4 and the storage battery 3 in sequence; wherein, the connecting plate 8 is provided with a guide groove and a strip-shaped hole 81, and the piston rod of the vertical cylinder 2 passes through the The elongated hole 81 is fixedly connected with the bottom of the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com