A material automatic packaging machine

An automatic packaging machine and material technology, applied in packaging and other directions, can solve the problems of poor control of filling, too tight filling, affecting packaging effect, etc., and achieve the effect of improving packaging grade and excellent filling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

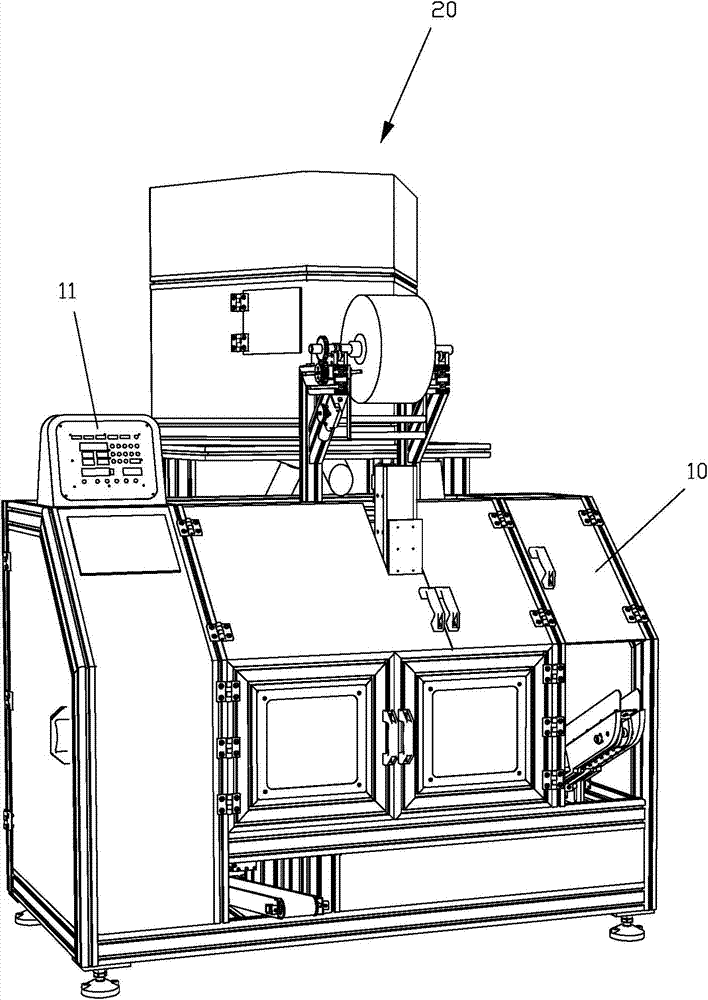

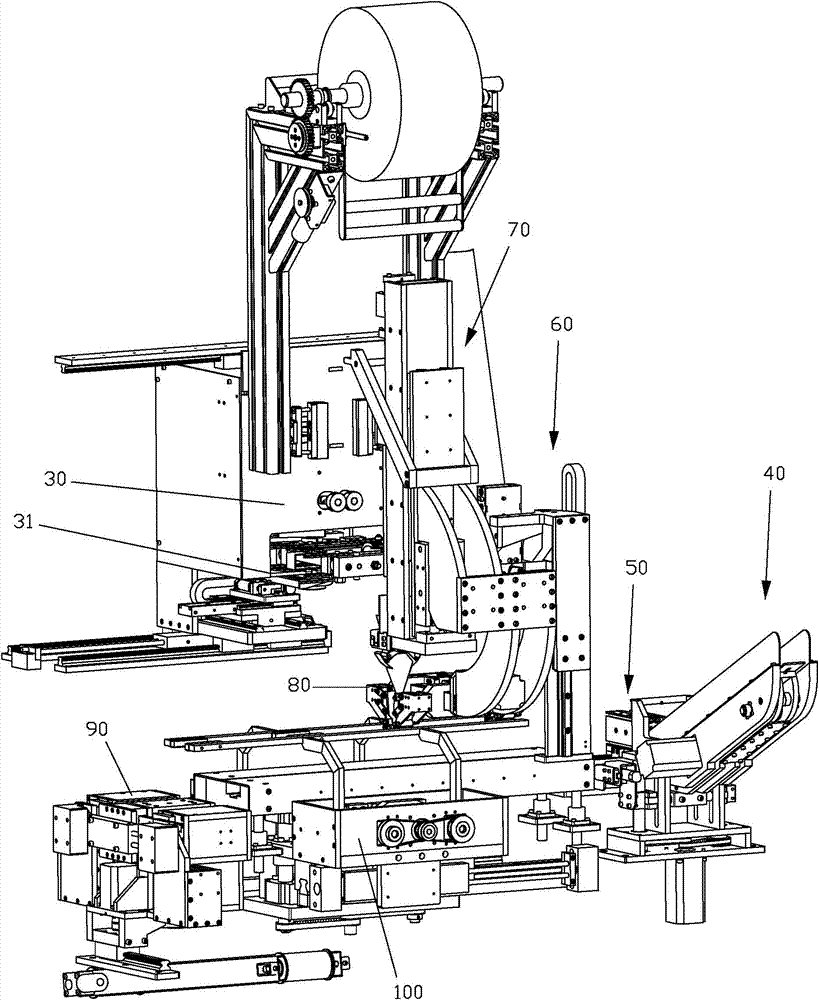

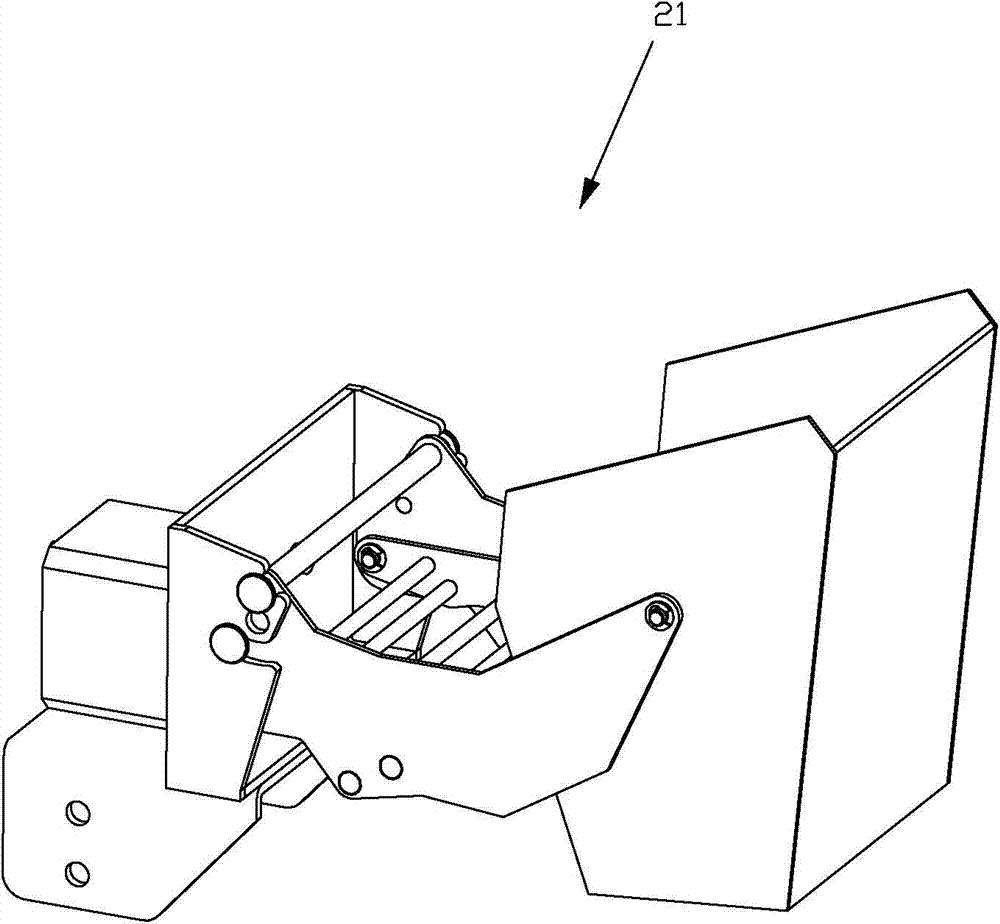

[0047] refer to figure 1 , a material automatic packaging machine of the present invention includes a housing 10, a control panel 11 is provided on the housing 10, the control panel 11 is connected with a control system, and a material dispensing mechanism 20 is located above the housing 10. Material packing mechanism 20 refers to the content in the inventor's patent CN201476856U, referring to image 3 , The weighing bucket 21 in the material packing mechanism 20 is a detachable structure, which is convenient for cleaning. In addition, in the present invention, the material sub-packaging mechanism 20 has a one-key discharge function, which can control the residual materials to be discharged from the storage hopper, the feeding device, the weighing device and the discharge device through the control panel 11 after a packaging program is completed. material.

[0048] refer to figure 2 A material automatic packaging machine of the present invention also includes an inner bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com