Winding packaging system for large gypsum board production line

A packaging system and gypsum board technology, which is applied in the field of winding packaging systems for large-scale gypsum board production lines, can solve the problems of easy deviation between the legs and the packing belt, affecting the packing quality, and difficult to purchase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

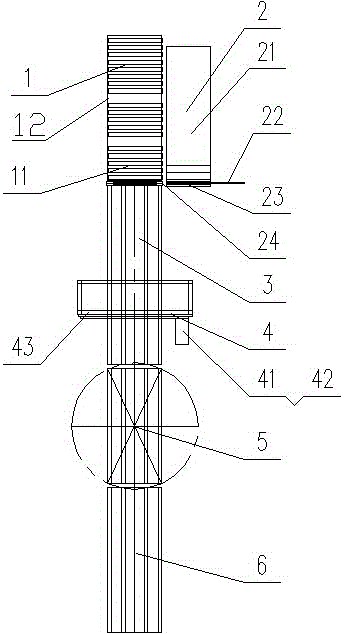

[0012] Such as figure 1 As shown, the winding packaging system of the large-scale gypsum board production line includes a transition roller conveying device 1, an automatic pad feeding device 2, a pad feeding and returning film conveying device 3, a fully automatic horizontal six-sided winding packaging device 4, and a circumferential Rotary conveying device 5 and miniature chain plate conveying device 6, described transition roller conveying device 1, pad strip feed back film conveying device 3, circumferential rotation conveying device 5 and miniature chain plate conveying device 6 are arranged in sequence, and described pad strip The automatic feeding device 2 is set on one side of the transition roller conveying device 1 and moves with the pad strip feeding and returning film conveying device 3, and the pad strip feeding and returning film conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com