Sweeper of belt conveyor and material conveying equipment

A belt conveyor and cleaner technology, which is applied to conveyor objects, cleaning devices, transportation and packaging, etc., can solve the problems of limited adjustment range of the angle of the cleaning main body, poor cleaning effect of the cleaner, and close contact of the scraper 13, etc. Achieve the effect of good angle adjustment performance, simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

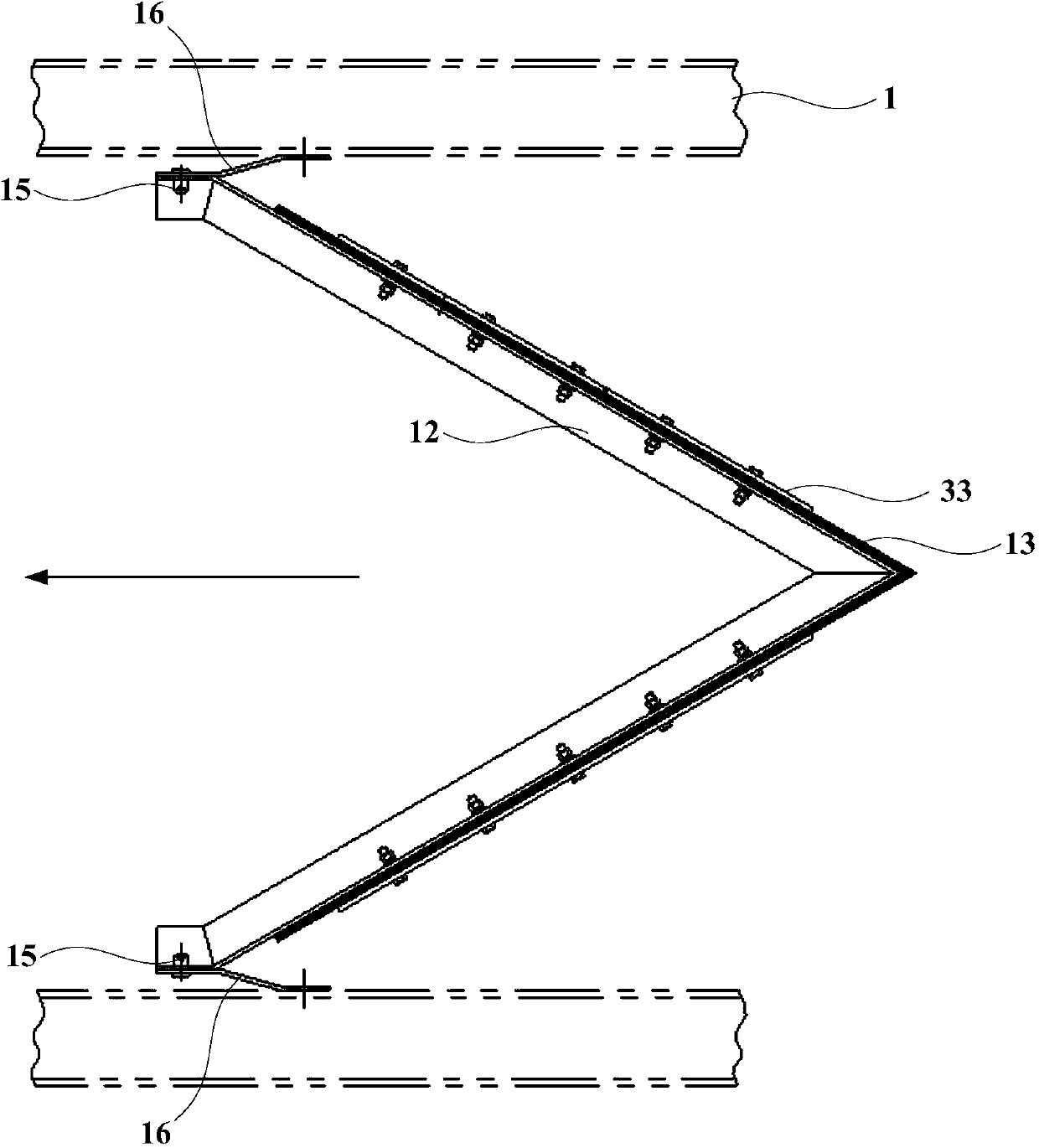

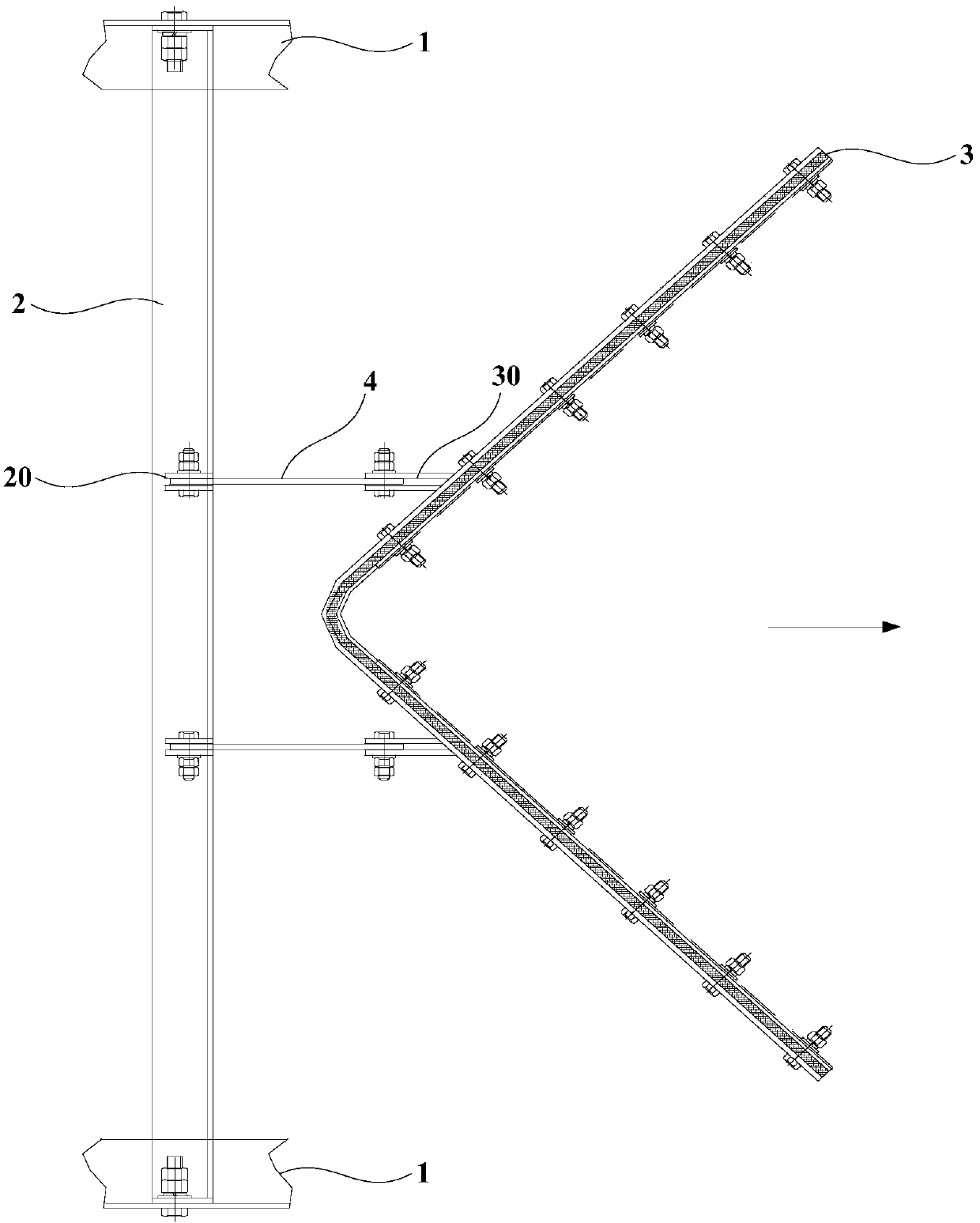

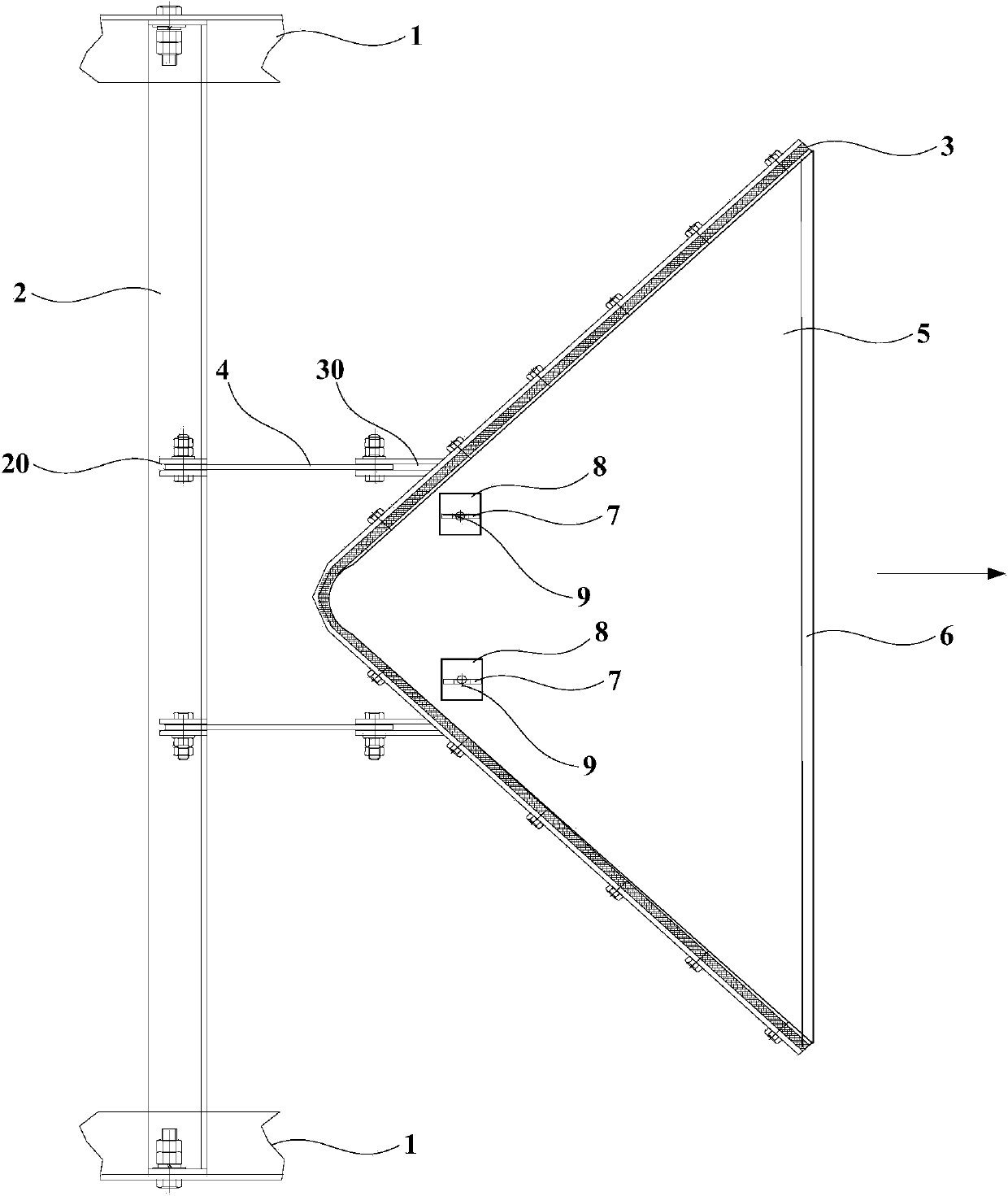

[0040] In order to improve the cleaning effect, an embodiment of the present invention provides a cleaner and material conveying equipment for a belt conveyor. In this technical solution, the connecting piece is respectively hinged with the fixed beam and the cleaning piece. Since there are two hinge points, the angle adjustment range of the cleaning piece is larger, so it can be in close contact with the vibrating conveyor belt at any time to improve the cleaning effect. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

[0041] In the present invention, under the situation of not stating to the contrary, the orientation words used as "up, down, front, back" are usually defined under the normal use of the cleaner of the belt conveyor provided by the present invention, for example figure 2 The direction of the middle arrow is the return running...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com