Longevous mullite brick for hot blast stove and preparation method thereof

A mullite brick and hot blast stove technology, applied in the field of refractory materials, can solve the problems of brick vault, poor creep resistance, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

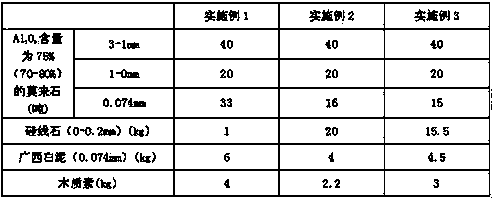

[0029] A method for preparing long-lived mullite bricks for hot blast stoves, comprising the following steps: a. Weighing the following preparation raw materials in mass percentages: containing Al 2 o 3 The mass percentage is 75%-95% of mullite of 70%-80%, 0%-20% of sillimanite, and 4%-6% of Guangxi white mud; 2-4% lignin; add water and mix to make adobe; b. drying; c. firing: the winding temperature is 1380°C-1480°C, and the optimal sintering temperature is 1430°C.

[0030] The mullite of the present invention is a high-alumina vanadium clay clinker homogenized material, wherein the mullite has a large particle size of 1-3 mm, a medium particle size of 0.075-1 mm and a fine powder fineness of ≤0.074 mm in a mass ratio of 4:2:1.5-3.5 It is obtained by mixing, the particle size of sillimanite is 0-0.2mm, and the particle size of white clay is 0.070-0.088mm.

[0031] The present invention uses Al in mullite 2 o 3 The mass percentage is 75% as an example for illustration.

...

Embodiment 4

[0070] Embodiment 4 organizational structure

[0071] Figure 8 A scanning electron microscope image of Example 4 (no sillimanite added) is given. It can be seen from the microstructure diagram that Example 4 has a denser structure and lower porosity. It can be seen from the energy spectrum and analysis results that almost all of them are mullite structures, which also confirms its high compressive strength macroscopically.

[0072] Figure 9 The scanning electron microscope picture of Example 5 (the addition of sillimanite is 10%) is given. From the energy spectrum and analysis results, it can be seen that there is a little corundum phase in the sample. The reason may be that the raw material has not been completely homogenized, and some corundum is contained in addition to mullite, so the corundum is introduced into the sample through the raw material. middle.

[0073] Figure 10 The scanning electron micrograph of sample example 6 (the addition of sillimanite is 20%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap