Construction method for splay supporting frame of bridge cast-in-place concrete formwork

A technology of concrete formwork and construction method, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems that the height of the support should not be too large, cannot be satisfied, and a large amount of economic investment, etc., to achieve the effect of reducing the project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

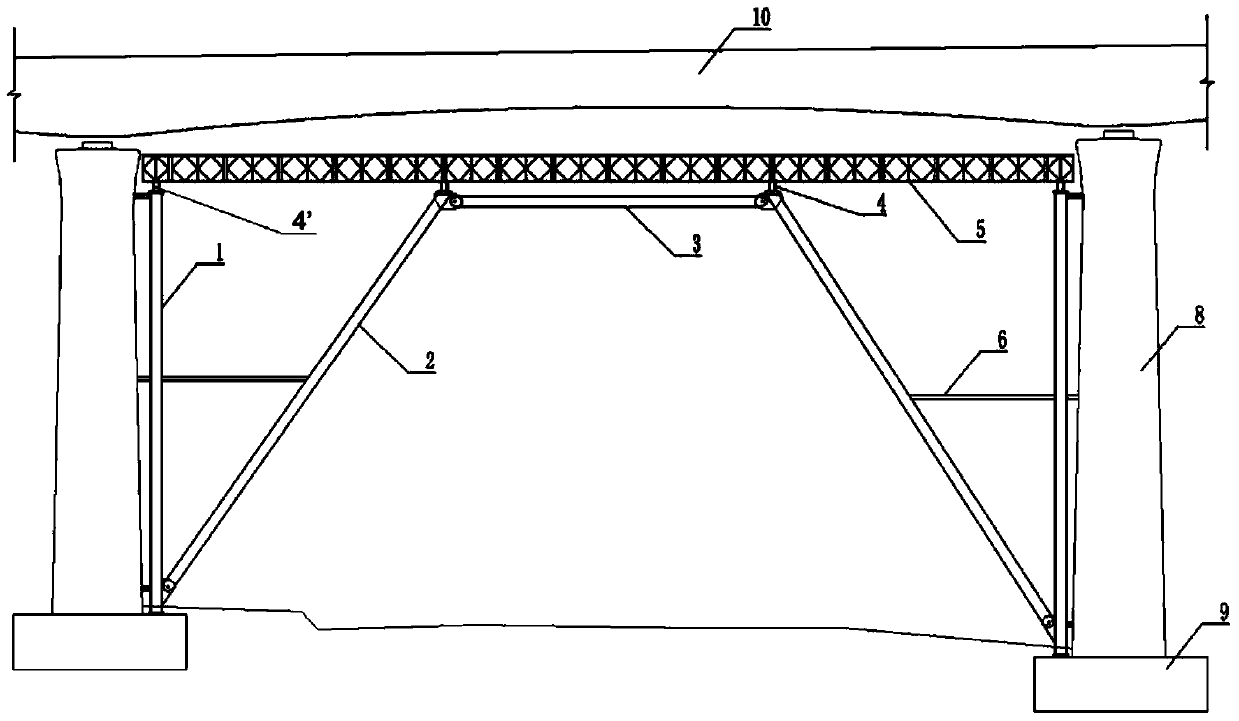

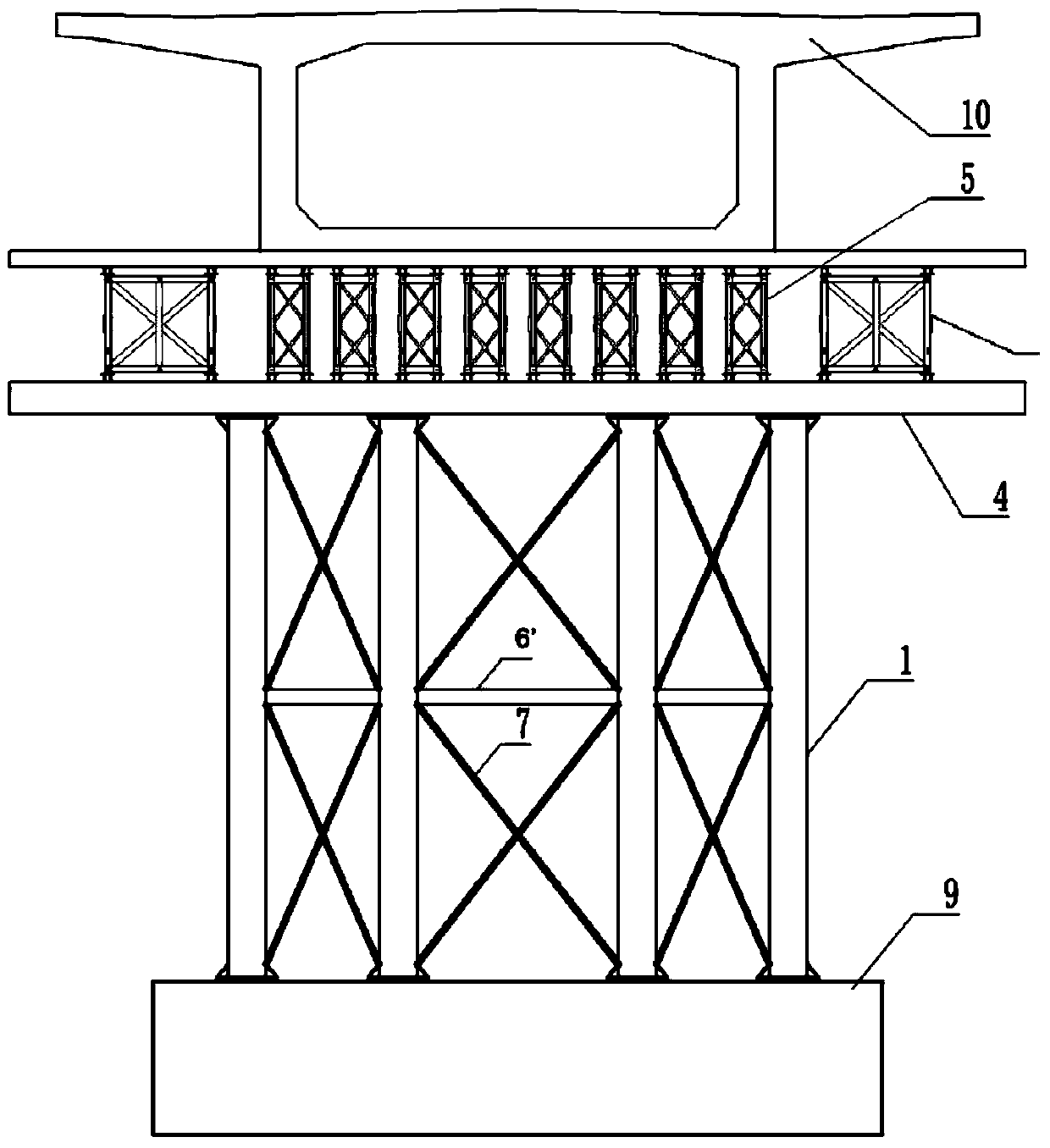

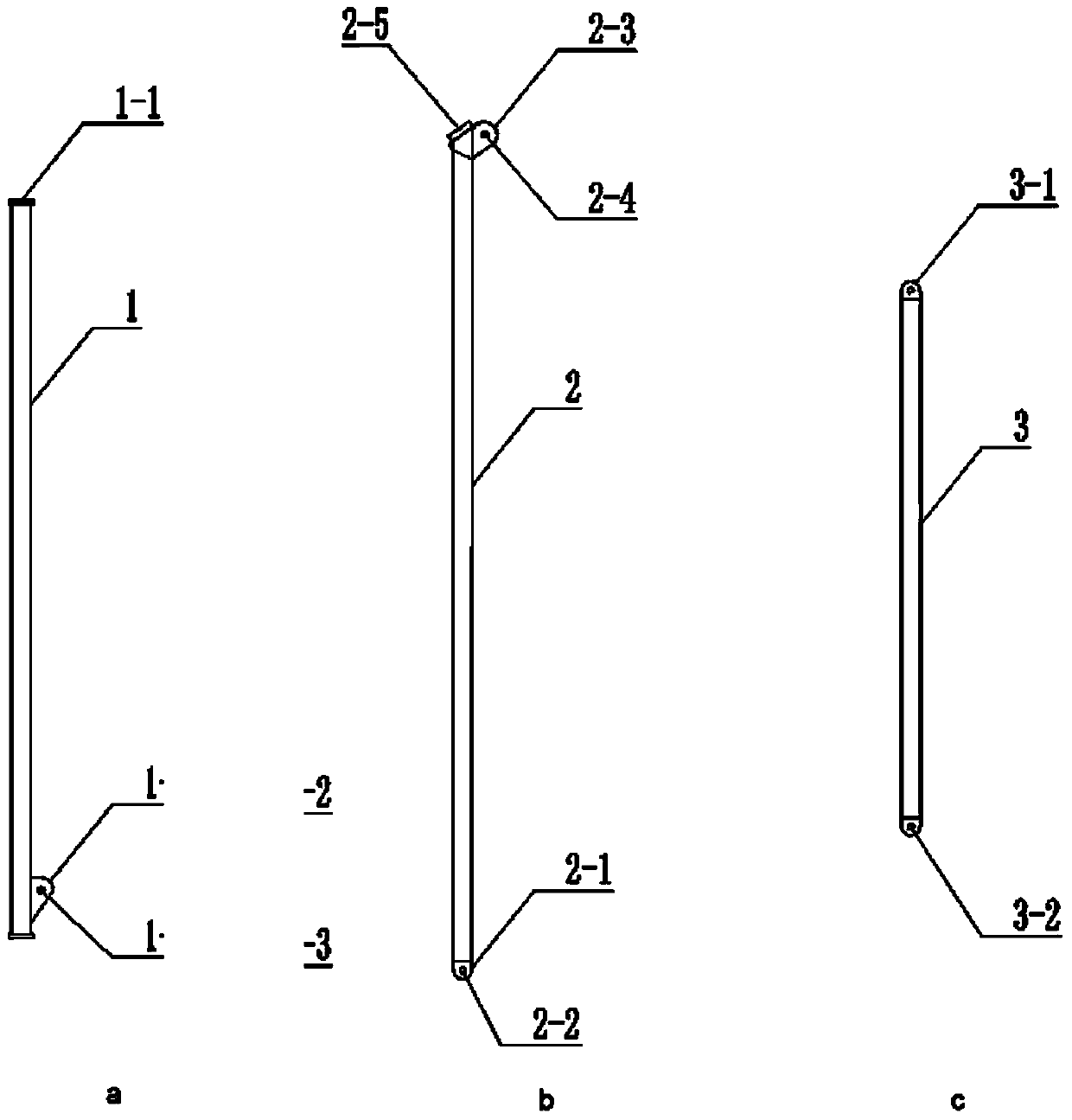

[0020] Such as figure 1 , figure 2 As shown, a bridge cast-in-place concrete formwork splayed support frame includes vertical bars 1, inclined legs 2, top braces 3, distribution beams 4, Bailey trusses 5, etc., wherein the vertical bars 1 are made of steel pipes, flanges 1-1 and gusset plate 1-2 ( image 3 a), the gusset plate 1-2 is provided with pin holes 1-3; the oblique leg 2 is composed of steel pipes, gusset plates 2-1, 2-3, pin holes 2-2, 2-4, and bearing support 2-5 ( image 3 b); the top support 3 is composed of steel pipes, gusset plates 3-1, and pin holes 3-2 ( image 3 c). The pin hole 1-3 on the gusset plate 1-2 of the vertical bar 1 is connected with the pin hole 2-2 on the gusset plate 2-1 of the diagonal leg 2 through a steel pin; the pin hole 2-2 on the gusset plate 2-3 of the diagonal leg 2 4 is connected with the pin hole 3-2 on the gusset plate 3-1 of the top support 3 by a steel pin.

[0021] Such as image 3 As shown, the vertical bar 1 is a seamle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com