Herringbone-tooth planet gearbox

A technology for planetary gearboxes and planetary gears, which is applied to gear transmissions, belts/chains/gears, transmission parts, etc., can solve problems such as large axial forces and difficult axial positioning of transmission mechanisms, and achieve improved bearing capacity, Simple structure and improved contact safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

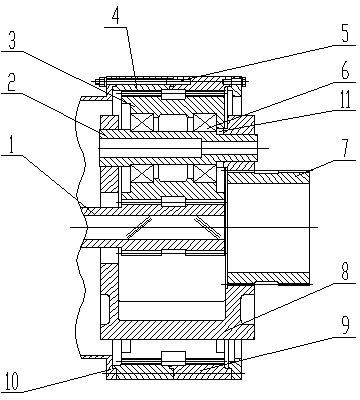

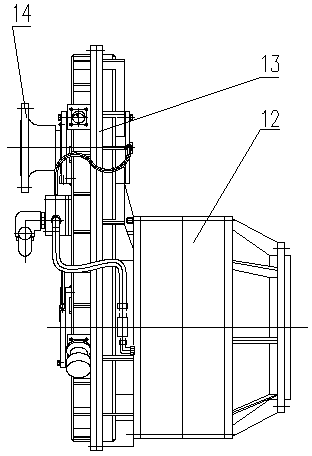

[0013] see Figure 1-2 Middle: The case body 10 of the planetary gearbox is fixedly connected to the frame, the two ring gears 4 and 9 are fixedly connected to the case body 10, the three planetary gear shafts 2 are connected to the planet carrier 8, and the three adjusting pads 11 are respectively Mounted on the three planetary wheel shafts 2, the three planetary wheels 3 are respectively installed on the three planetary wheel shafts 2 through three rolling bearings 6, and the adjustment pad 11 can be accurately adjusted according to the actual force of the planetary wheel 3 during operation during assembly The axial position of the planetary gear 3 achieves the purpose of uniform load of the three planetary gears 3, the center gear 1 is in the middle of the planetary gearbox 12, one end of the center gear 1 is the input end, and the tooth sleeve 7 is at the output end of the planetary gearbox 12 And extend out of the planetary gear box 12, the sun gear 1 is floatingly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com