LED car high beam

A technology of LED light source and high beam, applied in the direction of light source, electric light source, point light source, etc., can solve the problems of complex optical design, etc., and achieve the effects of low glare effect, high energy utilization rate, and convenient production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

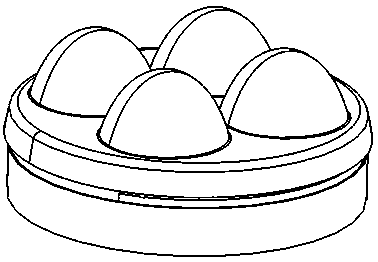

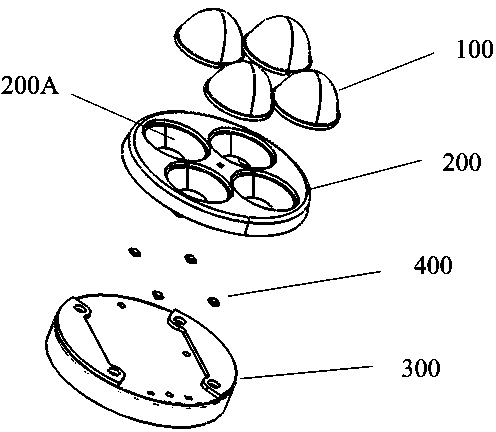

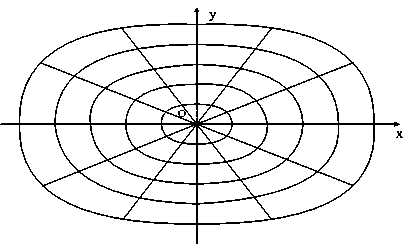

[0035] Such as figure 1 with figure 2 As shown, the LED car high beam provided by the present invention is composed of LED light source 400, free-form surface optical lens 100, lens holder 200 and base plate 300, the LED light source and lens support are fixed on the base plate, and the free-form surface optical lens is installed on the lens On the bracket, the distance between the light-emitting surface of the LED light source and the incident surface of the free-form optical lens is fixed by the height of the lens bracket. The LED car high beam has 4 LED light sources 400 and 4 free-form surface optical lenses 100, each free-form surface optical lens corresponds to each LED light source respectively, and the 4 LED light sources are fixed on the base plate 300 according to a certain position, and the lens bracket There are 4 circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com