Pulsating heat pipe with roughening structure

A pulsating heat pipe and roughening technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of long start-up time, limit the application of pulsating heat pipes, and start-up temperature rise, and achieve broad application prospects and shorten the start-up time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

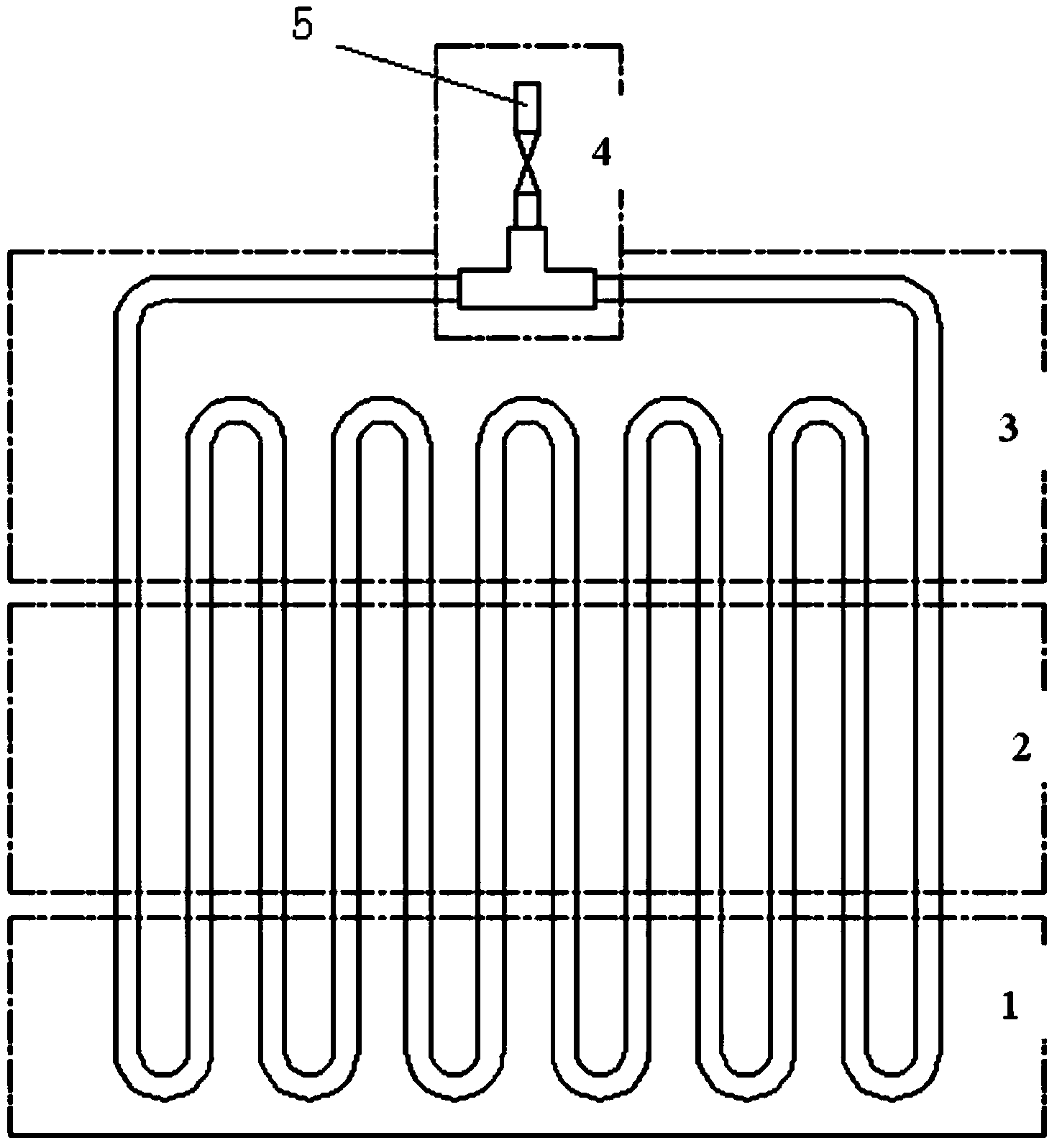

[0013] Such as figure 1 shown. The present invention has a pulsating heat pipe with a coarser structure, and acetone is poured into the pulsating heat pipe as a working medium; the pulsating heat pipe includes an evaporation section 1, a heat insulation section 2, a condensation section 3 and a working fluid perfusion section 4; the heat insulation section 2 and The condensation section 3 is integrally formed by capillary tubes; the connection between the evaporation section 1 and the heat insulation section 2 is welding; the two interfaces of the working fluid injection section 4 communicate with the tee pipe 5; the inner wall of the evaporation section 1 The surface is a granular structure (roughened structure), which can be processed by electroplating, electrochemical corrosion, chemical corrosion or powder sintering. The roughened structure helps to increase the radius of the nucleation point, which in turn facilitates the formation of new bubbles on the inner wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com