Electronic scale outlet balance flow control method

A flow control and outlet weighing technology, applied in the direction of weighing, measuring device, weighing equipment with continuous material flow, etc., can solve the problem of increasing the actual flow of downstream equipment, affecting the normal operation of downstream equipment, etc., to achieve the effect of increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

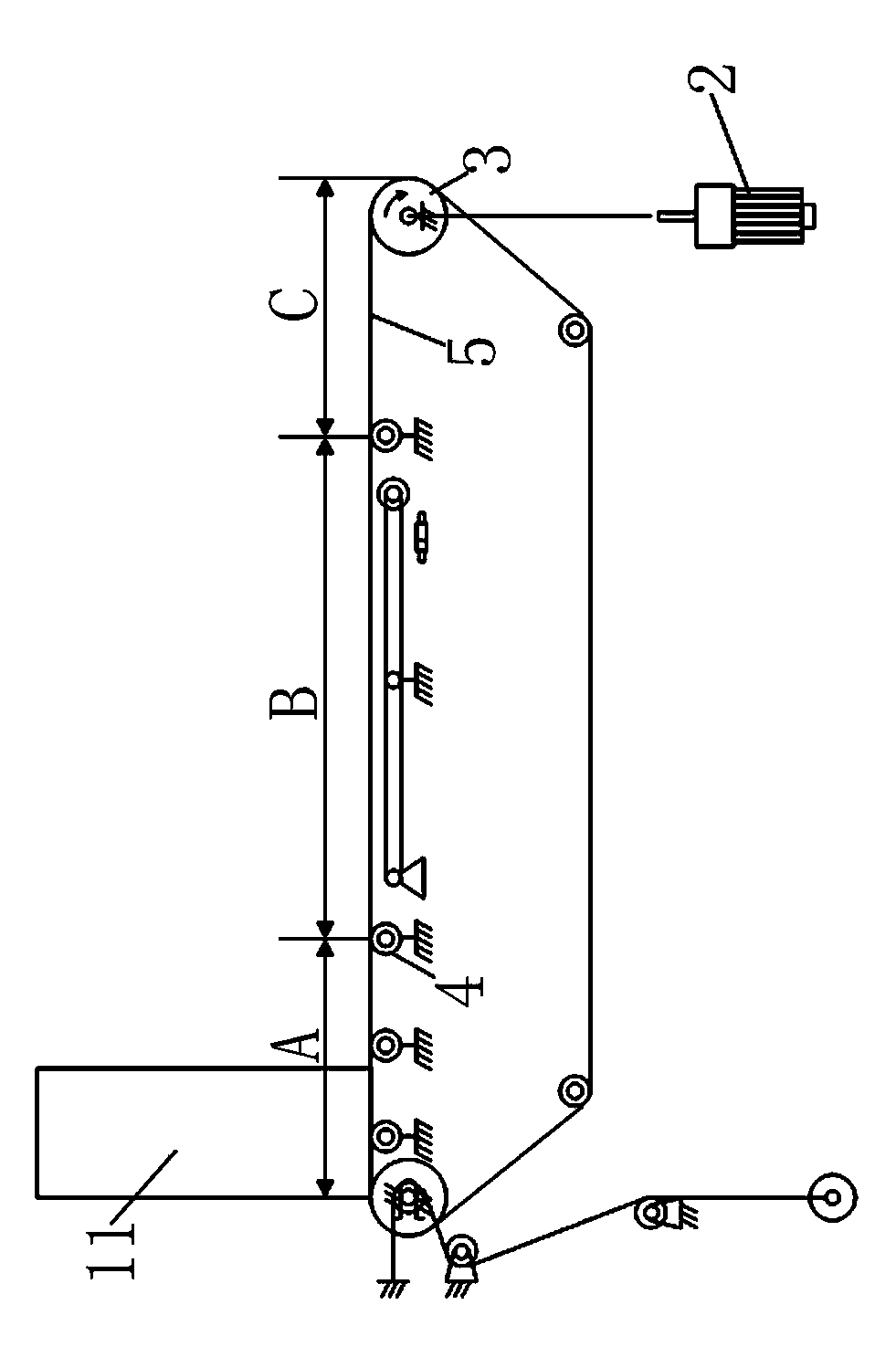

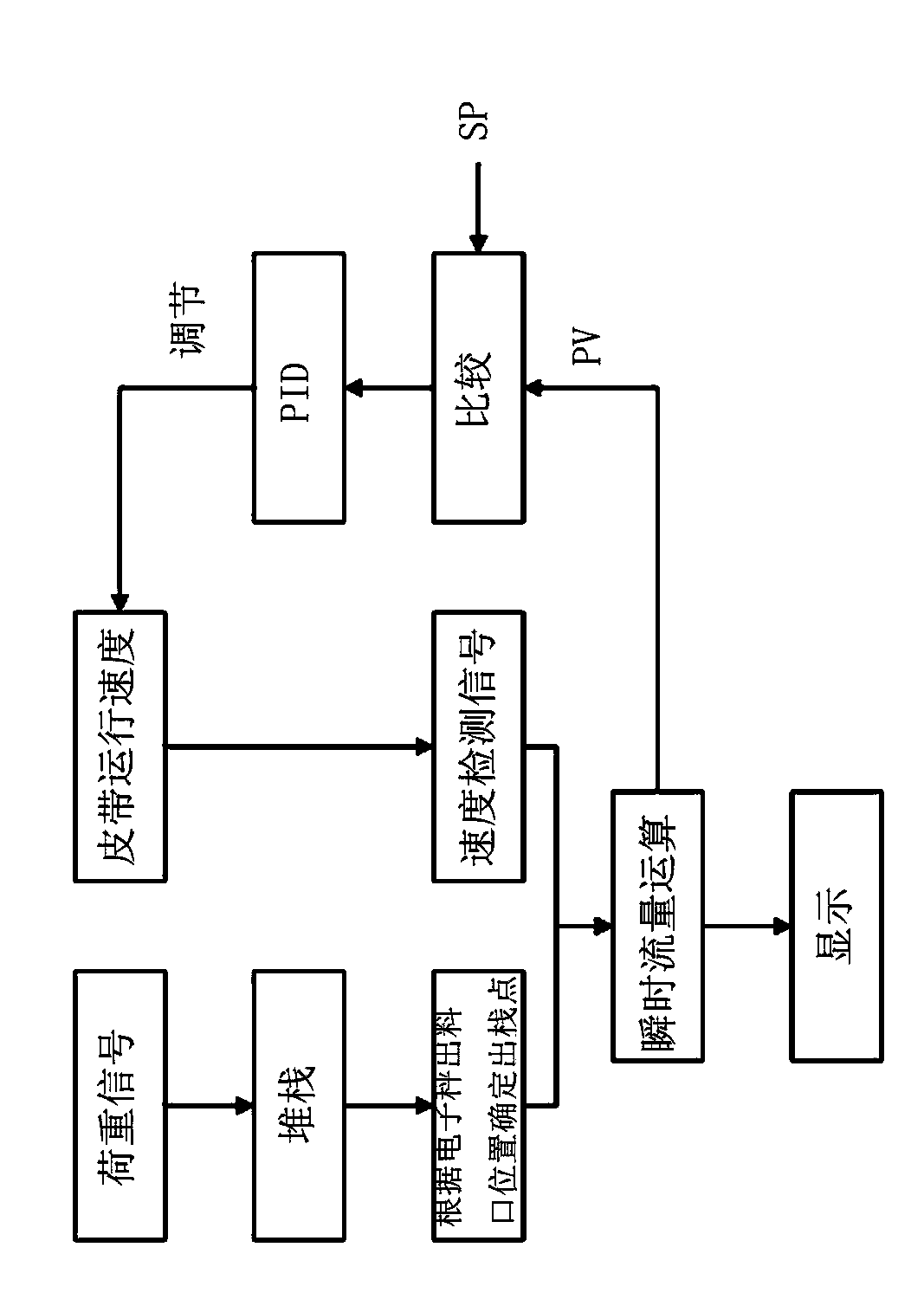

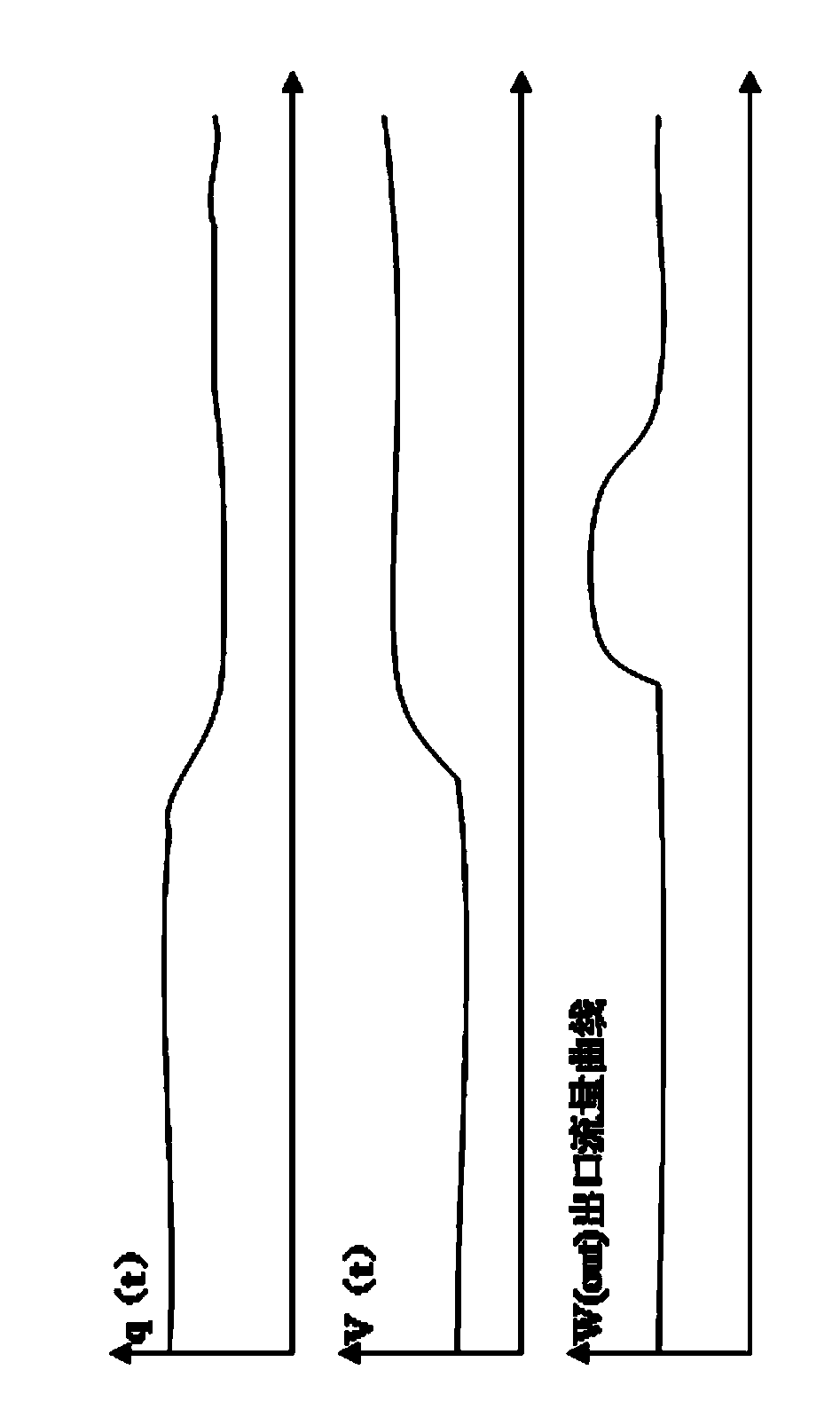

[0024] like figure 1 As shown, the flow control method of the traditional weighing area balance is to send a start signal to the electronic scale when the material in the limit tube reaches a certain level, and the motor 2 drives the transmission roller 3 and the drag roller 4 to drive the belt 5 to run, and the material is sent to the feeding area A. Go to weighing area B, calculate its instantaneous flow at the outlet of weighing area B, when its instantaneous flow deviates from the set flow, adjust the output frequency of its motor 2 through PID, thereby changing the running speed of belt 5, and realizing its stable instantaneous flow control purposes. When the supply of materials is insufficient, PID increases the frequency of the inverter to make the electronic scale run at high speed, and at the same time, the material in the discharge area C quickly passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com