Temperature difference power generation mouse

A thermoelectric power generation and mouse technology, which is applied in generators/motors, electrical components, data processing power supplies, etc., can solve problems such as insufficient power for the operation of the thermoelectric power generation mouse 10, and poor air cooling efficiency of the main casing 11, etc. To achieve the effect of effective power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

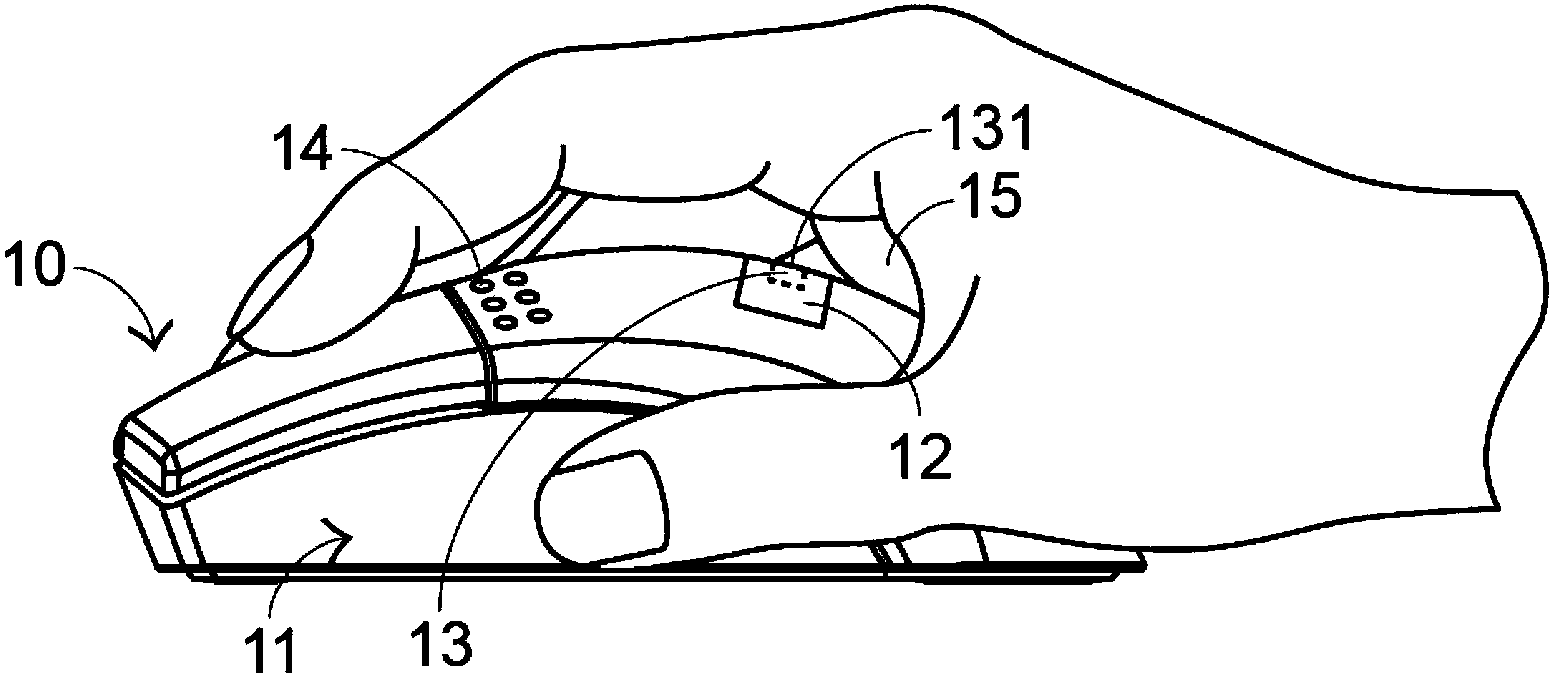

[0033] In order to improve the lack of the existing thermoelectric power generation mouse, the present invention arranges the heat conduction sheet and the thermoelectric power generation chip at the position equivalent to the button sheet, unlike the prior art where the heat conduction sheet and the thermoelectric power generation chip are arranged behind the mouse main casing end and provide cooling holes.

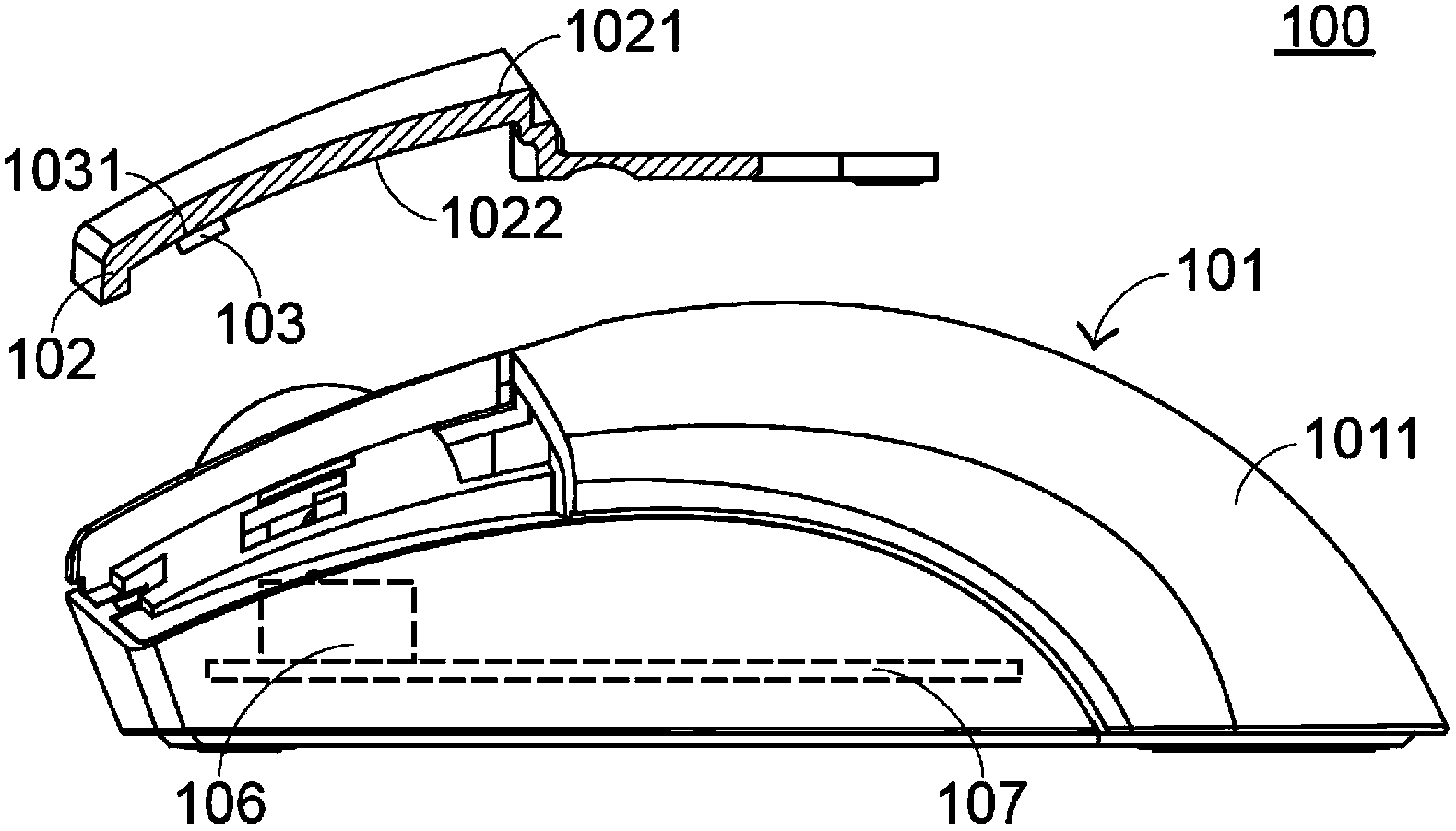

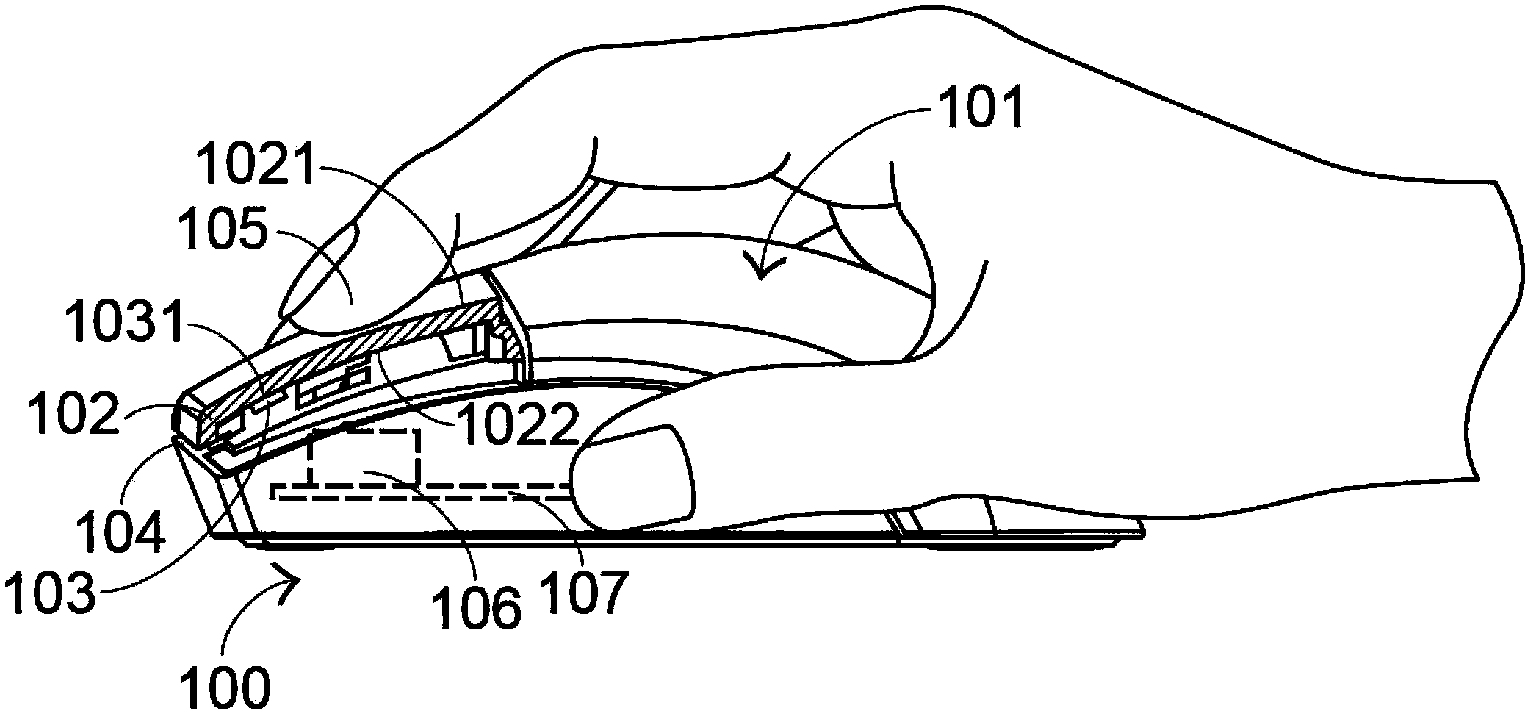

[0034] see figure 2 , which is an exploded and cross-sectional schematic diagram of the main parts of the first preferred embodiment of the thermoelectric power generation mouse of the present invention. figure 2 Among them, the thermoelectric mouse 100 includes a main casing 101 and a heat conduction sheet 102, and a first surface 1021 of the heat conduction sheet 102 extends from a surface 1011 of the main casing 101, so that the heat conduction sheet 102 and the main casing 101 jointly form a The overall appearance of the thermoelectric mouse 100. A thermoelectric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com